Do you have a question about the YASKAWA P7 and is the answer not in the manual?

Details model numbers and corresponding enclosure styles for different Yaskawa P7 drives.

Provides detailed dimensions for mounting various P7 Drive models, including NEMA 1 and Open Chassis types.

Presents heat loss data for 200V and 400V class P7 drives, indicating cooling methods.

Specifies vertical installation and required clearances for proper heat dissipation and cooling efficiency.

Provides instructions for safely removing and reattaching the terminal cover for wiring connections.

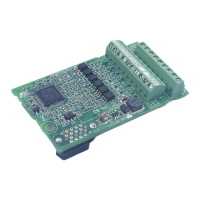

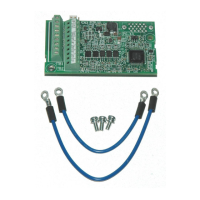

Illustrates the layout of control and main circuit terminal blocks for different P7 Drive models.

Details applicable wire sizes, connector specifications, and clamping torque for main circuit terminals based on drive model and HP.

Provides a comprehensive diagram illustrating all field wiring connections to the P7 Drive terminals.

Explains the components and functions of the digital operator display, including menu, data, and mode indicators.

Describes the function of each key on the digital operator for programming, operation, and monitoring.

Used to set and read the most commonly used parameters in the Drive, providing quick access to essential settings.

Allows setting and reading of all available parameters in the Drive, offering comprehensive control.

A checklist to ensure proper preparation before initiating the Drive start-up procedure, covering installation and verification.

Step-by-step instructions for powering up, configuring basic settings, and verifying the Drive operation.

Covers initial setup parameters like language selection, access level, and parameter initialization methods.

Configuration for Proportional-Integral (PI) control, enabling feedback and setpoint adjustments for closed-loop operations.

Guides through the auto-tuning process to optimize motor control and performance by adjusting parameters.

Explains how faults are detected and displayed, and procedures for resetting faults.

Provides general troubleshooting steps for common issues like parameters not setting or errors being displayed.

Step-by-step guide for testing main circuit components like diodes, fuses, and transistors using a multimeter.

Outlines regular checks to be performed on the Drive and motor with and without power applied.

Provides a schedule for inspecting various Drive components based on operating conditions and time intervals.

Comprehensive list of all Drive parameters, including number, name, description, range, factory setting, and menu location.

Lists parameters related to fault tracing, providing details about the fault condition at the time of occurrence.

Explains how to set the Drive capacity based on the model number and lists corresponding o2-04 settings.

Details electrical and performance specifications for 208-240Vac and 480Vac P7 Drive models.

Explains how to configure and use Modbus communication, including specifications and connection details.

Provides reference data, monitor data, and broadcast data tables for Modbus communication.

Recommends fuse and circuit breaker ratings per NEC for branch circuit short circuit protection for 208-240Vac and 480Vac inputs.

Lists and describes peripheral devices like magnetic contactors, reactors, and noise filters that may be required.

Lists primary spare parts for the power PCB, transistor module, and fans for 208/230/240Vac models.

Lists recommended EMC filters, their model numbers, current ratings, dimensions, and nominal HP for different Drive models.

| Manufacturer | Yaskawa |

|---|---|

| Model | P7 |

| Number of I/O Points | Varies by configuration |

| Storage Temperature | -20°C to 60°C |

| Dimensions | Varies depending on model (refer to specific model datasheet) |

| Weight | Varies depending on model (refer to specific model datasheet) |