Programming 5 - 46

! L6 Torque Detection

" L6-01 Torque Detection Selection 1

" L6-02 Torque Detection Level 1

Setting Range: 0 to 300% of Drive rated output current

Factory Default: 15% of Drive rated output current

" L6-03 Torque Detection Time 1

Setting Range: 0.0 to 10.0 Seconds

Factory Default: 10.0 Seconds

The Drive can be programmed to indicate when either an overtorque or an undertorque conditions exist. A digital output must

be programmed for “Torque Detection”, (H2-01/H2-02= “B: Trq Det 1 N.O.” or “17: Trq Det 1 N.C.). A warning of an

overtorque condition can indicate a jam and an undertorque condition can indicate a broken belt, no water in a pump, or other

loss of load.

To configure Torque Detection requires the following decisions:

1. Do you wish to check for an overtorque condition or an undertorque condition?

2. Do you wish to check for the torque condition whenever the drive is running or only at speed agree? Nuisance detection

during acceleration, when variable torques are normally required, can be avoided.

3. Do you want the drive to fault if the torque condition is detected or only alarm and continue operation?

The following table can help choose the proper setting for Torque Detection Selection 1 to get the wanted results.

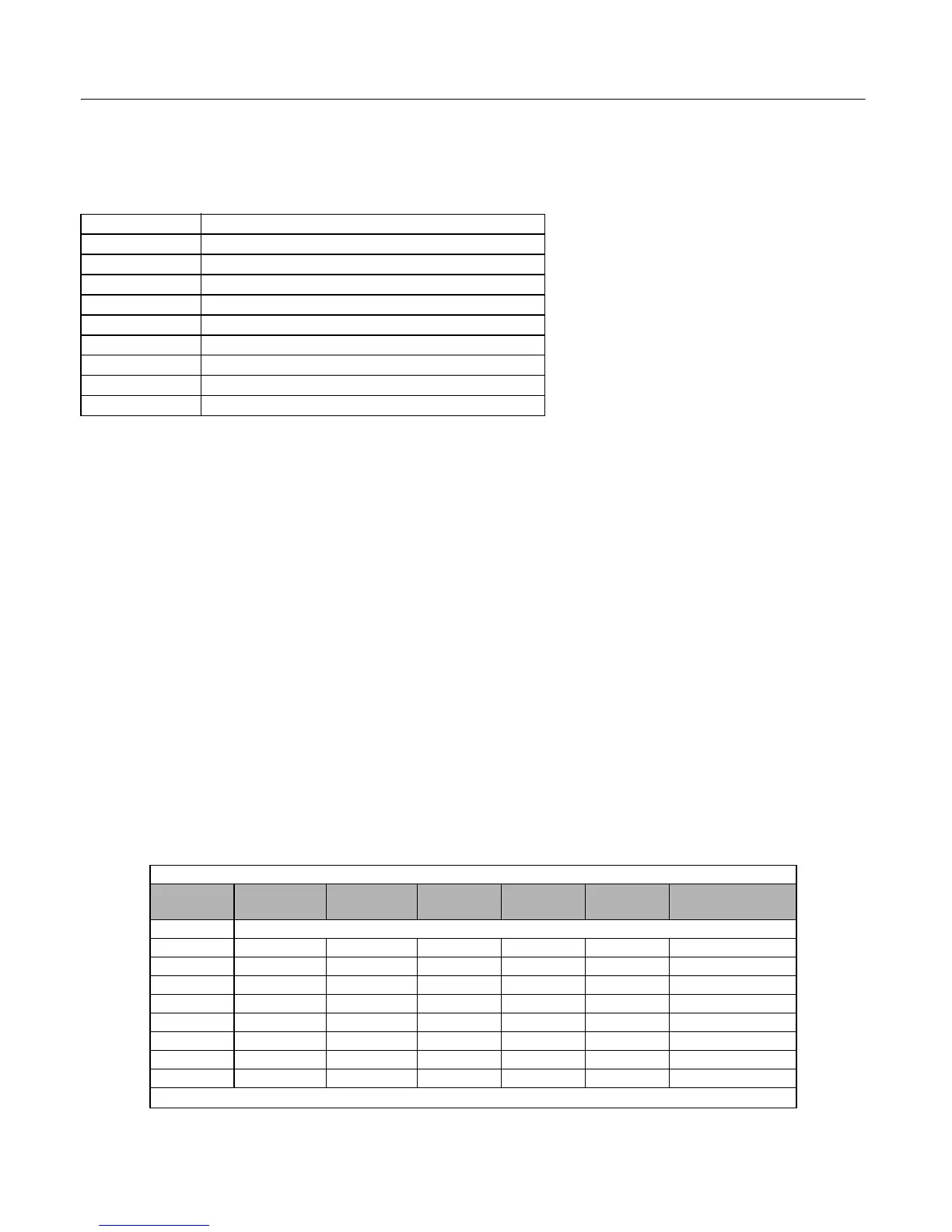

Setting Description

0 Disabled (factory default)

1OL@SpdAgree - Alm

2OL At Run -Alm

3 OL@SpdAgree - Flt

4OL At Run - Flt

5UL@SpdAgree - Alm

6 UL at Run - Alm

7 UL@SpdAgree - Flt

8UL At Run - Flt

Table 6 L6-01 Setting Choices

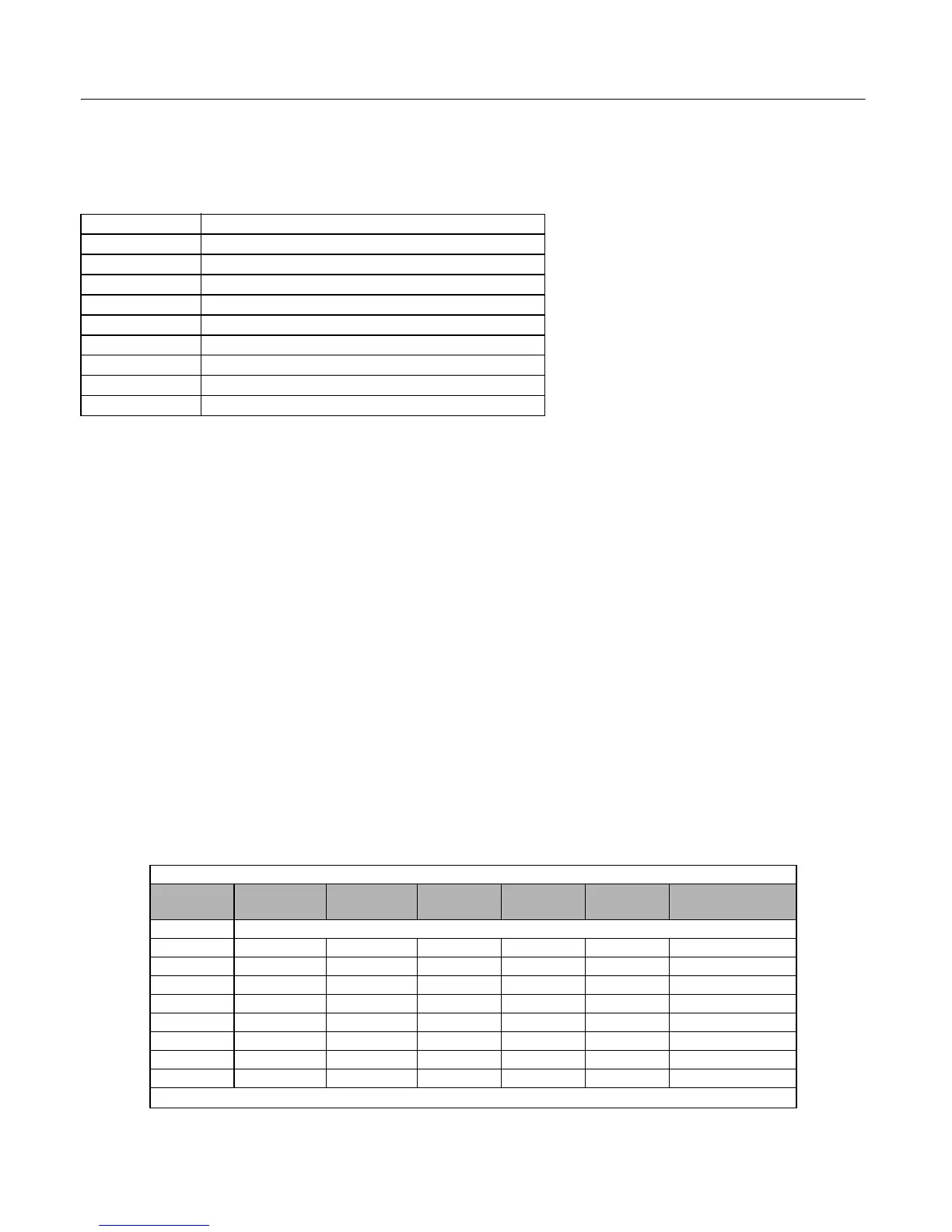

L6-01

Setting

Overtorque Undertorque Fault Alarm

Always

Detected

Only Detected @

Spd Agree

0 Torque Detection Disabled

1X X X

2X XX

3X X X

4X X X

5* X X X

6XXX

7X X

8X X

*Suggested settings for Loss of Load indication

Loading...

Loading...