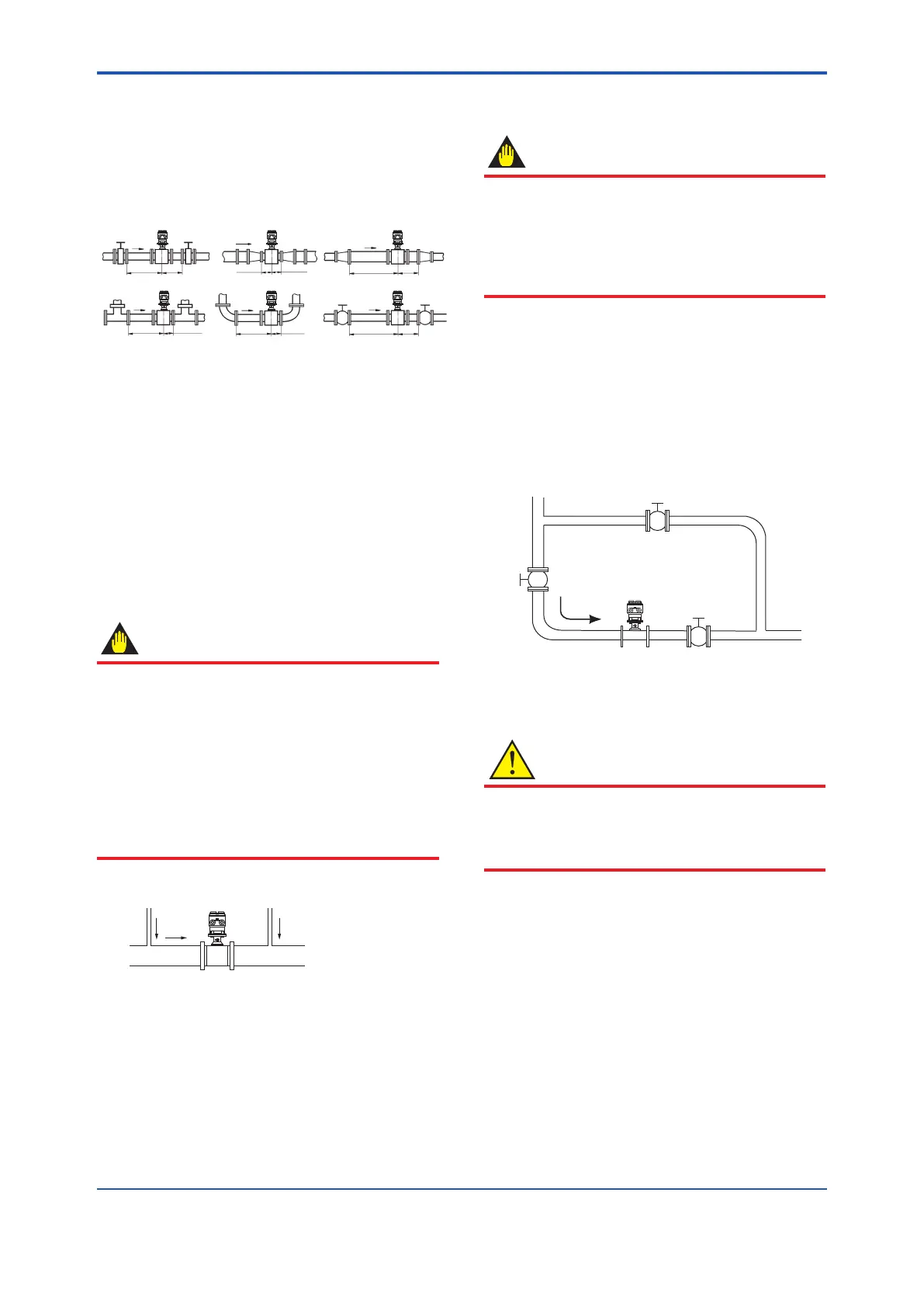

(3) Required Lengths of Straight Runs

Based on JIS B 7554 “Electromagnetic Flowmeters” and

our piping condition test data, we recommend the piping

conditions as shown in the following gures. This is not

always enough when the piping line incorporates multiple

conditions at the same time.

Gate valve

fully open

5D or more

2D

or more

Reducer

pipe

Expander

pipe

0 is allowable. 0 is allowable.

10D or more

10D or more

Tee

90-degree bend

Various valves

0 is allowable.5D or more 0 is allowable.5D or more

2D

or more

Figure 3.1.1 Required Lengths of Straight Runs

*1: Do not install anything in the vicinity that may interfere

with the magnetic eld, induced signal voltages, or ow

velocity distributions of the owmeter.

*2: A straight run may not be required on the downstream

side of the owmeter. However, if a downstream valve

or other tting causes irregularity or deviation in ows,

provide a straight run of 2D to 3D on the downstream side.

*3: The valves shall be mounted on the downstream side so

that deviated ows do not occur in the sensor and to avoid

startup from an empty condition.

*4: In case the piping conditions are compounded, install

on the straight pipe section where the upstream part is

sufciently rectied.

(4) Maintaining Stable Fluid Conductivity

IMPORTANT

Do not install the owmeter where uid conductivity

tends to become uneven. If chemicals are fed near

the upstream side of a magnetic owmeter, they may

affect the ow rate’s indications. To avoid this situation,

it is recommended that the chemical feed ports be

located on the downstream side of the owmeter. If

it is unavoidable that chemicals must be fed on the

upstream side, provide a sufcient length of straight

run (approximately 50D or more) to ensure the proper

mixture of uids.

Upstream side

Figure 3.1.2 Chemical Injection

(5) Precautions for Use of Liquid Sealing

Compounds

IMPORTANT

Care must be taken in using liquid sealing compounds

on the piping, as it may have a negative inuence on

the ow indications by owing out and covering the

surfaces of an electrode or grounding ring. In particular,

care must be taken if a liquid sealing compound is used

in the case of vertical piping.

(6) Service Area

Select locations where there is adequate space to service

installing, wiring, overhauling, etc.

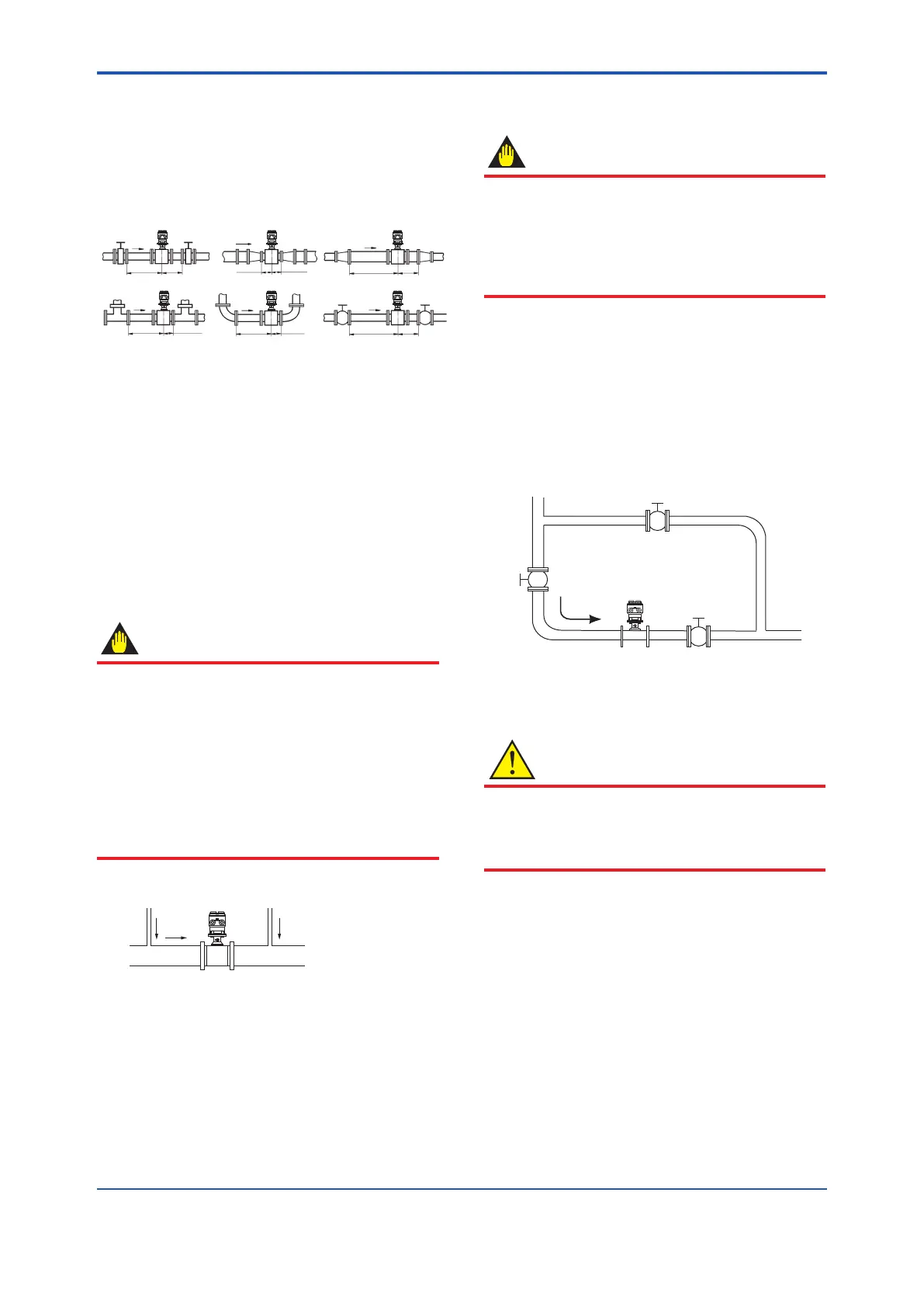

(7) Bypass Line

It is recommended to install a bypass line to facilitate

maintenance and zero adjustment.

Block valve

Figure 3.1.3 Bypass Line

(8) Supporting the Flowmeter

CAUTION

Do not secure the owmeter separately to prevent the

vibrations, shocks, and expansion and contraction forces

of the piping from affecting it. Fix the pipes rst, then

support the owmeter with the pipes.

<3. Installation>

10

IM 01E24A01-01EN

Loading...

Loading...