<3. Installation>

17

IM 01E24A01-01EN

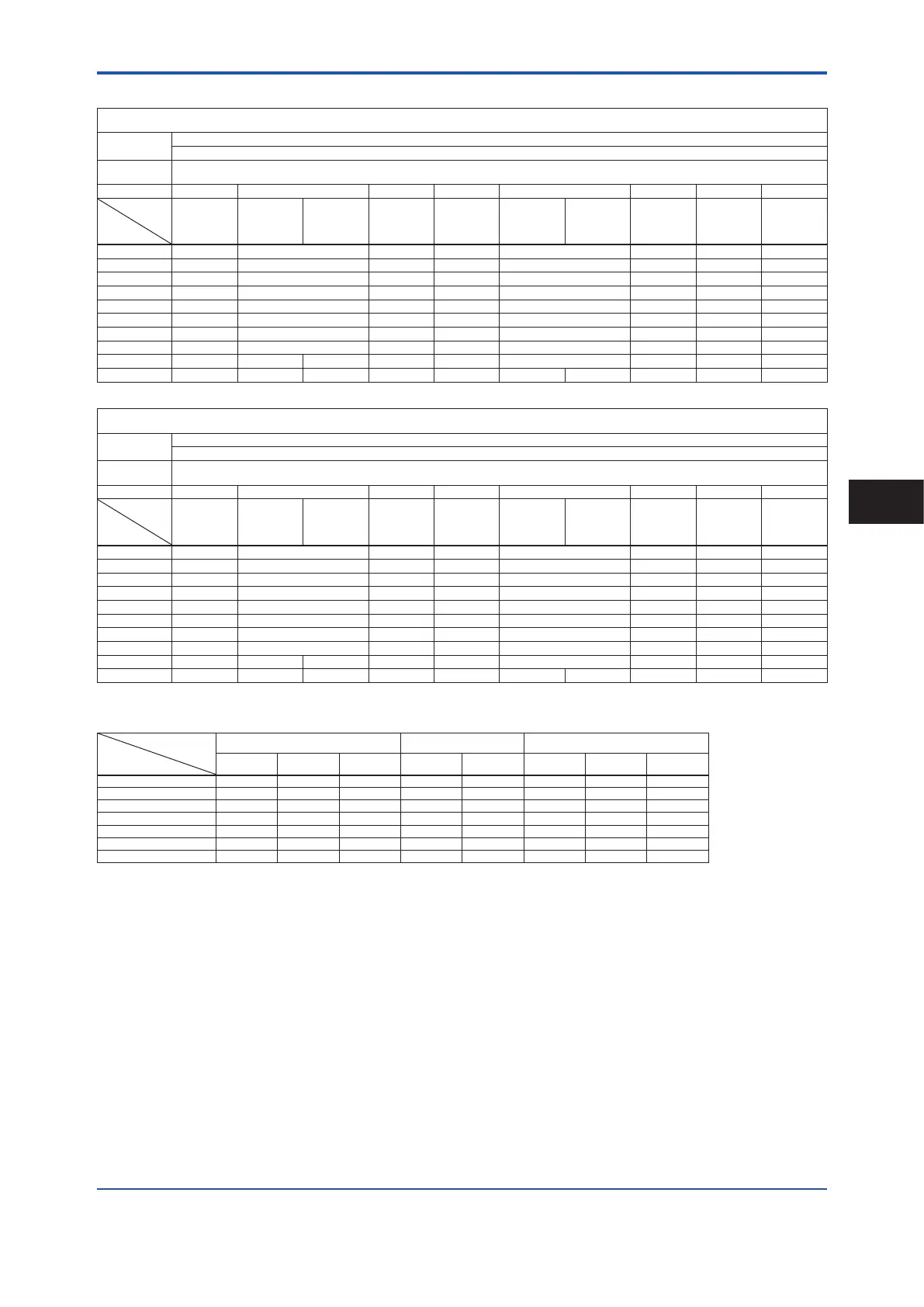

Table 3.3.2 Wafer Type Tightening Torque Values for Metal Piping

Tightening torque values for Natural Hard Rubber/Natural Soft Rubber/Polyurethane Rubber lining (N·m)

Gasket types

within sensor

Natural Soft Rubber/Polyurethane Rubber lining: No gasket (Standard)

Natural Hard Rubber lining: Non-asbestos gasket, PTFE-sheathed non-asbestos gasket, or the equivalent in hardness

Gasket types

for user’s ange

Non-asbestos gasket, PTFE-sheathed non-asbestos gasket (Optional code BSF), or the equivalent in hardness

Flange Rating JIS 10K ASME Class 150 EN PN10 JIS 20K ASME Class 300 EN PN16 EN PN40 JIS F12

Thread

Standards

Size mm

Metric

screw

Metric

screw

Unied

screw

Metric

screw

Metric

screw

Metric

screw

Unied

screw

Metric

screw

Metric

screw

Metric

screw

25 11.2 to 18.4 8.5 to 12.6 ― 11.8 to 18.4 11.0 to 16.7 ― 8.8 to 12.7 ―

32 12.6 to 20.5 8.2 to 11.7 ― 13.5 to 20.5 10.8 to 15.5 ― 10.5 to 15.2 ―

40 19.5 to 31.3 14.3 to 20.2 ― 21.3 to 31.3 22.8 to 31.9 ― 19.0 to 26.7 ―

50 24.8 to 38.7 22.5 to 33.2 ― 13.0 to 19.3 13.9 to 19.8 ― 25.8 to 33.8 ―

65 39.2 to 59.9 36.4 to 51.9 ― 19.7 to 30.0 23.2 to 35.5 13.8 to 20.9 ― ―

80 21.6 to 33.1 37.0 to 49.2 ― 27.4 to 41.4 23.0 to 33.7 14.8 to 21.5 ― 43.7 to 66.2

100 29.2 to 42.8 24.2 to 31.6 ― 37.7 to 53.5 31.8 to 43.2 20.1 to 26.8 ― 58.9 to 85.6

125 45.9 to 65.6 34.1 to 40.5 52.9 to 71.7 37.8 to 46.2 26.1 to 32.0 ― 49.5 to 69.9

150 44.9 to 58.9 39.4 to 44.9 38.3 to 43.0 ― 33.4 to 43.0 27.3 to 32.7 32.2 to 37.6 ― 48.7 to 62.9

200 36.3 to 43.3 57.5 to 63.2 56.0 to 61.6 36.7 to 42.1 41.3 to 45.5 41.5 to 45.7 42.9 to 47.2 27.1 to 29.8 ― 45.3 to 52.0

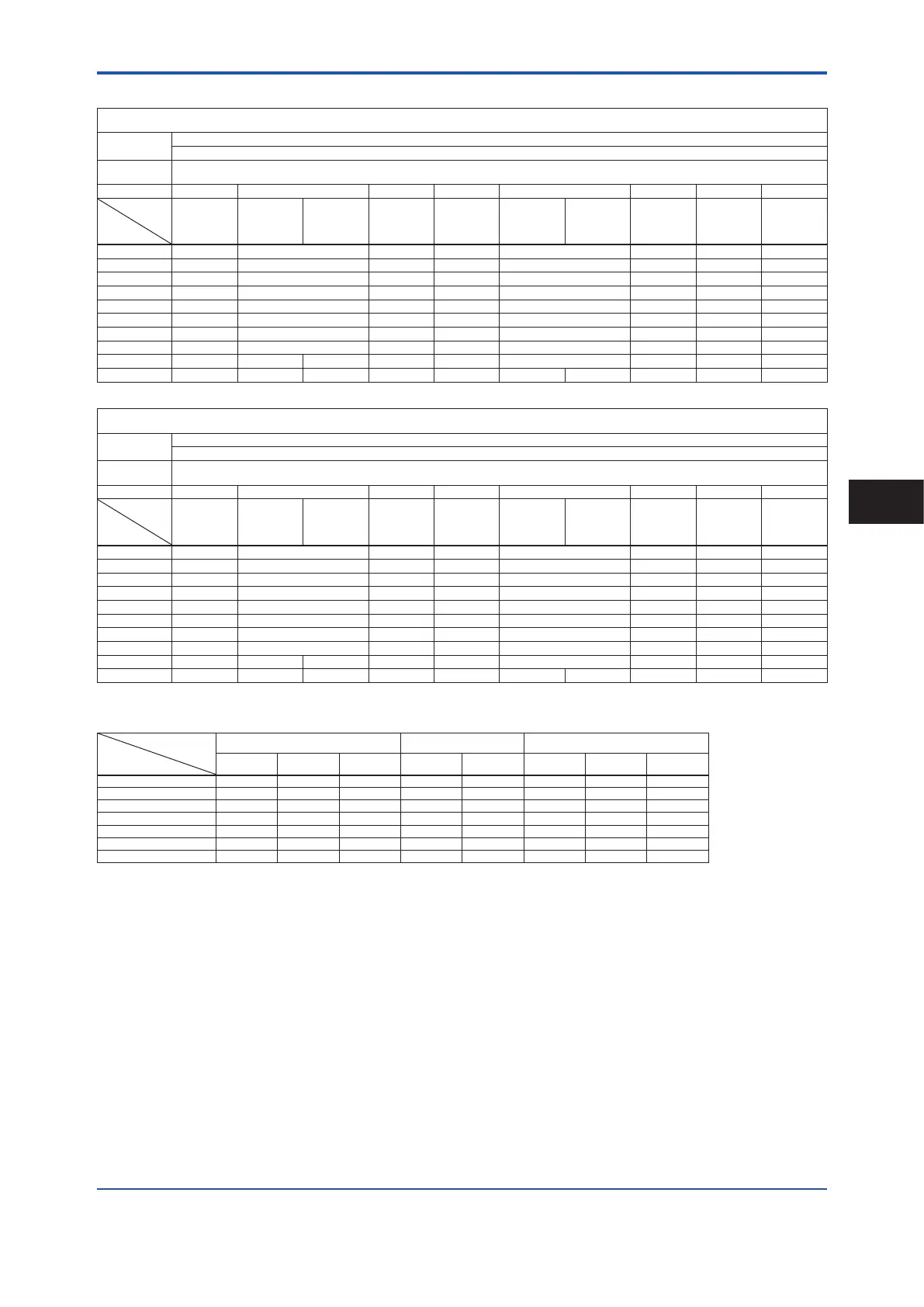

Tightening torque values for Natural Hard Rubber/Natural Soft Rubber/Polyurethane Rubber lining (in.·lbf)

Gasket types

within sensor

Natural Soft Rubber/Polyurethane Rubber lining: No gasket (Standard)

Natural Hard Rubber lining: Non-asbestos gasket, PTFE-sheathed non-asbestos gasket, or the equivalent in hardness

Gasket types

for user’s ange

Non-asbestos gasket, PTFE-sheathed non-asbestos gasket (Optional code BSF), or the equivalent in hardness

Flange Rating JIS 10K ASME Class 150 EN PN10 JIS 20K ASME Class 300 EN PN16 EN PN40 JIS F12

Thread

Standards

Size in.

Metric

screw

Metric

screw

Unied

screw

Metric

screw

Metric

screw

Metric

screw

Unied

screw

Metric

screw

Metric

screw

Metric

screw

1.0 99.1 to 162.9 75.2 to 111.5 ― 104.4 to 162.9 97.4 to 147.8 ― 77.9 to 112.4 ―

1.25 111.5 to 181.4 72.6 to 103.6 ― 119.5 to 181.4 95.6 to 137.2 ― 92.9 to 134.5 ―

1.5 172.6 to 277.0 126.6 to 178.8 ― 188.5 to 277.0 201.8 to 282.3 ― 168.2 to 236.3 ―

2.0 219.5 to 342.5 199.1 to 293.8 ― 115.1 to 170.8 123.0 to 175.2 ― 228.3 to 299.2 ―

2.5 346.9 to 530.2 322.2 to 459.4 ― 174.4 to 265.5 205.3 to 314.2 122.1 to 185.0 ― ―

3.0 191.2 to 293.0 327.5 to 435.5 ― 242.5 to 366.4 203.6 to 298.3 131.0 to 190.3 ― 386.8 to 585.9

4.0 258.4 to 378.8 214.2 to 279.7 ― 333.7 to 473.5 281.5 to 382.4 177.9 to 237.2 ― 521.3 to 757.6

5.0 406.2 to 580.6 301.8 to 358.5 468.2 to 634.6 334.6 to 408.9 231.0 to 283.2 ― 438.1 to 618.7

6.0 397.4 to 521.3 348.7 to 397.4 339.0 to 380.6 ― 295.6 to 380.6 241.6 to 289.4 285.0 to 332.8 ― 431.0 to 556.7

8.0 321.3 to 383.2 508.9 to 559.4 495.6 to 545.2 324.8 to 372.6 365.5 to 402.7 367.3 to 404.5 379.7 to 417.8 239.9 to 263.8 ― 400.9 to 460.2

Table 3.3.3 Centering Device Identication (Natural Hard Rubber/Natural Soft Rubber/Polyurethane Rubber lining)

Flange Rating

Size

mm (inch)

JIS ASME EN

10K 20K F12 Class 150 Class 300 PN10 PN16 PN40

50 (2.0) B B — B F — — F

65 (2.5) B B — B G — F —

80 (3.0) B F H F C — G —

100 (4.0) B F H C H — F —

125 (5.0) B C C G D — F —

150 (6.0) C D D C E — C —

200 (8.0) C D D D E C C —

*: Each centering device is engraved with a character as identication.

Installation

3

Loading...

Loading...