5120416-XIM-C-0216

36 Johnson Controls Unitary Products

Air Balance

Start the supply air blower motor. Adjust the resistances in both

the supply and the return air duct systems to balance the air

distribution throughout the conditioned space. The job

specifications may require that this balancing be done by

someone other than the equipment installer.

To check the supply air CFM after the initial balancing has been

completed:

1. Remove the two 5/16” dot plugs from the blower motor and

the filter access panels shown in the Unit Dimensions and

Rear View Clearances Figure 6.

2. Insert at least 8" of 1/4 inch tubing into each of these holes

for sufficient penetration into the air flow on both sides of

the indoor coil.

NOTE: The tubes must be inserted and held in a position

perpendicular to the air flow so that velocity pressure

will not affect the static pressure readings.

3. Using an inclined manometer, determine the pressure drop

across a dry evaporator coil. Since the moisture on an

evaporator coil may vary greatly, measuring the pressure

drop across a wet coil under field conditions would be

inaccurate. To assure a dry coil, the compressors should

be deactivated while the test is being run.

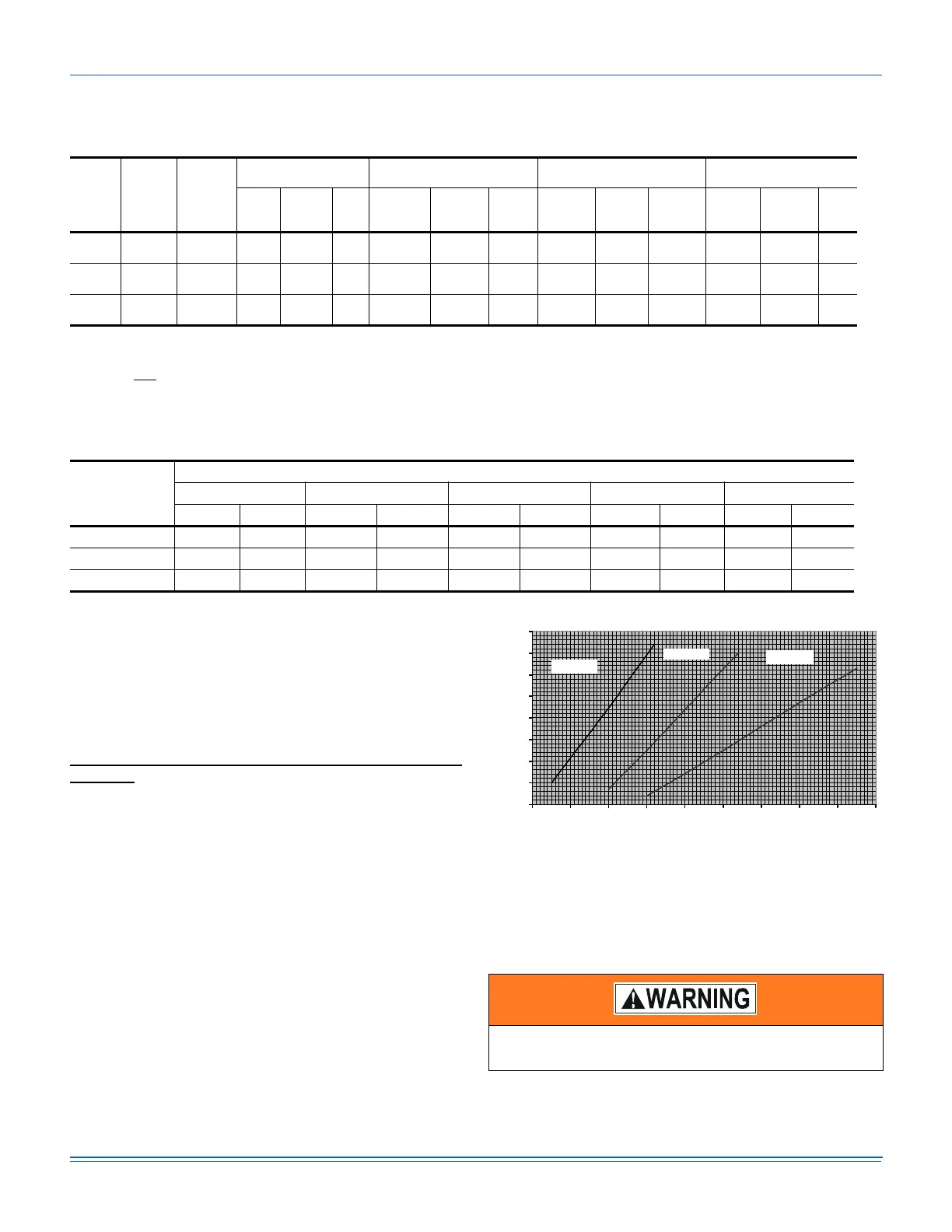

Figure 22: Pressure Drop Across A Dry Indoor Coil Vs.

Supply Air CFM For All Unit Tonnages

4. Knowing the pressure drop across a dry coil, the actual

CFM through the unit can be determined from the curve in

Pressure Drop vs. Supply Air CFM Figure 22.

After readings have been obtained, remove the tubes and reinstall the two 5/16” dot plugs that were removed in Step 1.

Table 14: Blower Motor And Drive Data

MODEL

SIZE

DRIVE

1

1. All 50 Hz DM180-300 models come standard with factory filtered High Static Drive.

BLOWER

RANGE

(RPM)

MOTOR

2

2. All motors have a nominal speed of 1450 RPM, a 1.15 service factor and a solid base. They can operate to the limit of their service factor because

they are located in the moving air, upstream of any heating device.

ADJUSTABLE MOTOR PULLEY

3

3. Do NOT close this pulley below 1 turn open.

FIXED BLOWER PULLEY

BELT

(NOTCHED)

kW/HP FRAME

EFF.

(%)

DESIG-

NATION

PITCH

DIA.

(mm/IN.)

BORE

(mm/IN.)

DESIG-

NATION

PITCH

DIA.

(mm/IN.)

BORE

(mm/IN.)

DESIG-

NATION

PITCH

LENGTH

(mm/IN.)

QTY.

180

High

Static

1030/1240 3.7/5.0 184 T 83 1VP62

109-135

4.3-5.3

29/1-1/8 BK75 175/6.9 25/1 BX68 1773/69.8 1

240

High

Static

895-1080 5.6/7.5 213 T 87 1VP75

140-165

5.5-6.5

35/1-3/8 BK100 239/9.4

30/1-3/16

4

4. Requires bushing (included in kit).

BX81 2103/82.8 1

300

High

Static

950/1130 7.5/10 254 T 89

1LVP58

B70A

157-188

(6.2-7.4)

A2

Bushing

1B5V94 241 (9.5)

B

Bushing

5VX840 2134/84 1

Table 15: Power Exhaust Performance

MOTOR

SPEED

STATIC RESISTANCE OF RETURN DUCTWORK, IWG

0.2 0.3 0.4 0.5 0.6

CFM KW CFM KW CFM KW CFM KW CFM KW

HIGH* 5250 0.83 4500 0.85 4200 0.88 3750 0.93 3000 0.99

MEDIUM 4900 0.77 3900 0.79 3500 0.82 2900 0.85 - -

LOW 4400 0.72 3700 0.74 3000 0.78 - - - -

Failure to properly adjust the total system air quantity

can result in extensive blower damage.

0.25

0.3

0.35

0.4

0.45

0.5

0.55

0.6

0.65

45678910111213

NOMINAL CFM (THOUSANDS) SUPPLY AIR

PRESSURE DROP (IWG)

240 MBH

Loading...

Loading...