25

Emergency Heat (W) - The blower will be started on “W” speed,

10 seconds later the first stage of electric heat will be turned on.

If the emergency heat demand is not satisfied after 2 minutes the

second electric heat stage will be energized.

Blower (G) - The blower will start immediately upon receiving a

thermostat G command. If there are no other commands from the

thermostat the ECM will run on “G” speed until the G command is

removed. Regardless of blower input (G) from the thermostat, the

blower will remain on for 30 seconds at the end of each heating

cycle.

Cooling Operation

In all cooling operations, the reversing valve directly tracks the O

input. Thus, anytime the O input is present, the reversing valve will

be energized.

Cooling, 1st Stage (Y1, O) - The blower is started on “Y1” speed

immediately and the compressor is energized 10 seconds after the Y1

input is received.

Cooling, 2nd Stage (Y1, Y2, O) - The compressor will be staged

to full capacity 20 seconds after Y2 input is received. The 5 speed

ECM blower will shift to Y2 speed immediately.

Emergency Shutdown - Four (4) seconds after a valid ES input,

P2-7 is present, all control outputs will be turned off and remain

off until the emergency shutdown input is no longer present. The

first time that the compressor is started after the control exits the

emergency shutdown mode, there will be an anti-short cycle delay

followed by a random start delay. Input must be tied to common to

activate.

Continuous Blower Operation - The blower output will be

energized any time the control has a G input present, unless the

control has an emergency shutdown input present. The blower

output will be turned off when G input is removed.

Load Shed - The LS input disables all outputs with the exception

of the blower output. When the LS input has been cleared, the anti-

short cycle timer and random start timer will be initiated. Input must

be tied to common to activate.

Aurora ‘Base’ Control LED Displays

These three LEDs display the status, configuration, and fault

codes for the control. These can also be read in plain English via

the Aurora AID Tool.

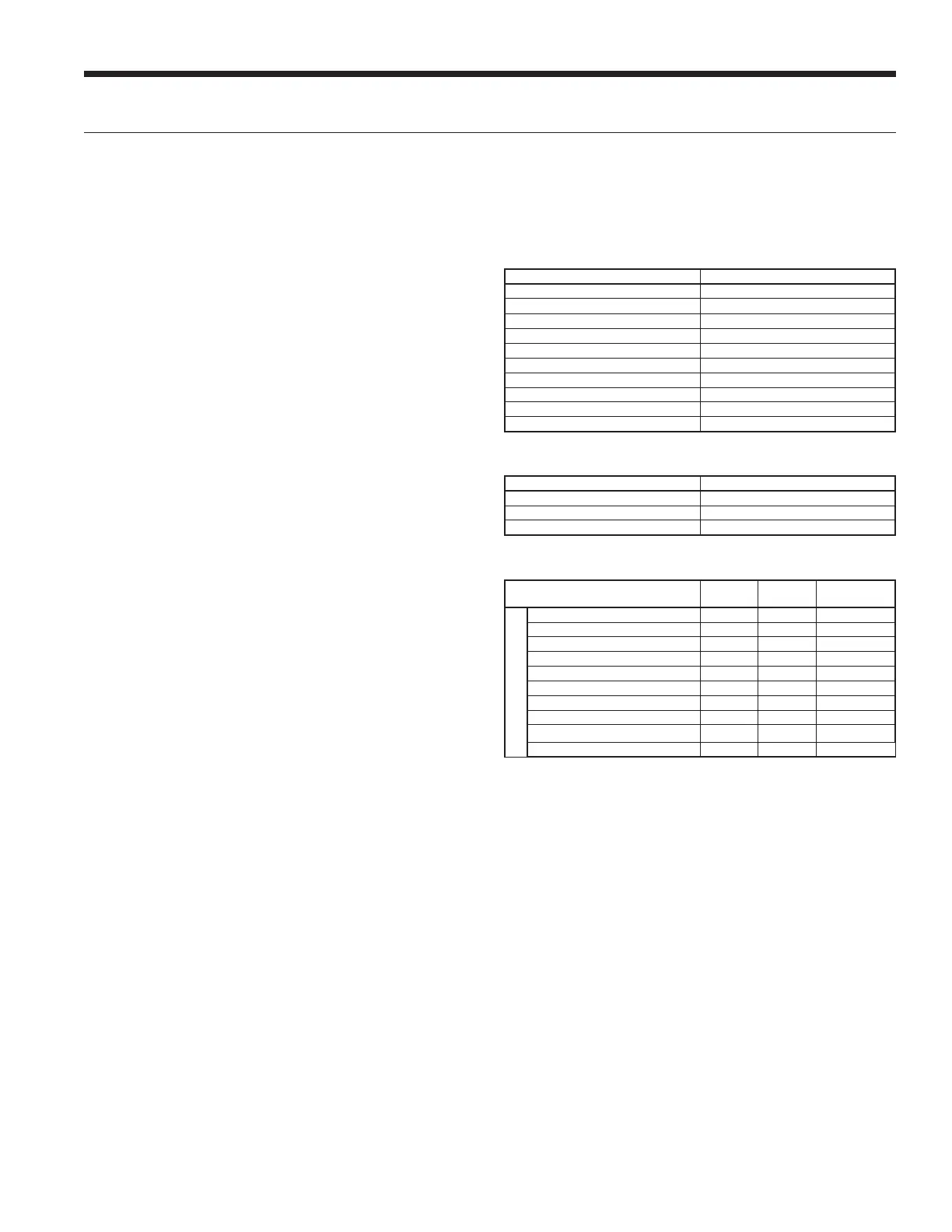

Status LED (LED3, Green)

Description of Operation Fault LED, Green

Normal Mode ON

Control is Non-functional OFF

Test Mode Slow Flash

Lockout Active Fast Flash

Dehumidification Mode Flash Code 2

(Future Use) Flash Code 3

(Future Use) Flash Code 4

Load Shed Flash Code 5

Emergency Shutdown Flash Code 6

Smart Grid Flash Code 7

Configuration LED (LED2, Yellow)

Description of Operation Configuration LED, Yellow

No Software Overwritten Flashing ECM Setting

DIP Switch was Overwritten Slow Flash

ECM Configuration Mode Fast Flash

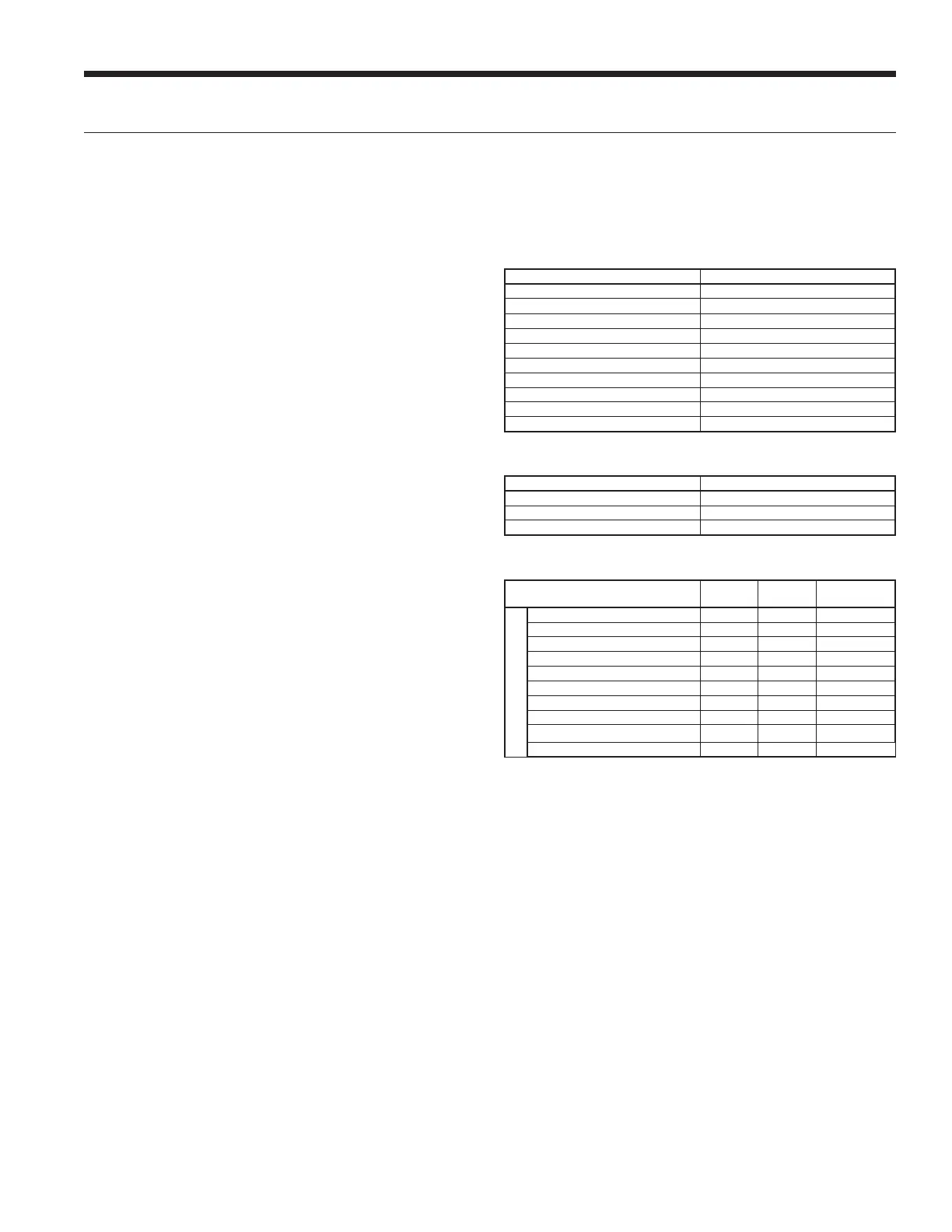

Fault LED (LED1, Red)

Red Fault LED

LED Flash

Code*

Lockout Reset/Remove

ABC Basic Faults

Normal - No Faults OFF –

Fault - Input 1 No Auto

Fault - High Pressure 2 Yes Hard or Soft

Fault - Low Pressure 3 Yes Hard or Soft

Fault - Freeze Detection FP2 4 Yes Hard or Soft

Fault - Freeze Detection FP1 5 Yes Hard or Soft

Fault - Condensate Overflow 7 Yes Hard or Soft

Fault - Over/Under Voltage 8 No Auto

Fault - FP1 Sensor Error 11 Yes Hard or Soft

Fault - CritComErr 19 NO Auto

NOTE: All codes >11 use long flash for tens digit and short flash for the ones digit. 20,

30, 40, 50, etc. are skipped.

The Aurora ‘Base’ Control System cont.

LX SERIES INSTALLATION MANUAL

Loading...

Loading...