FORM 160.73-O2 (605)

11

YORK INTERNATIONAL

2

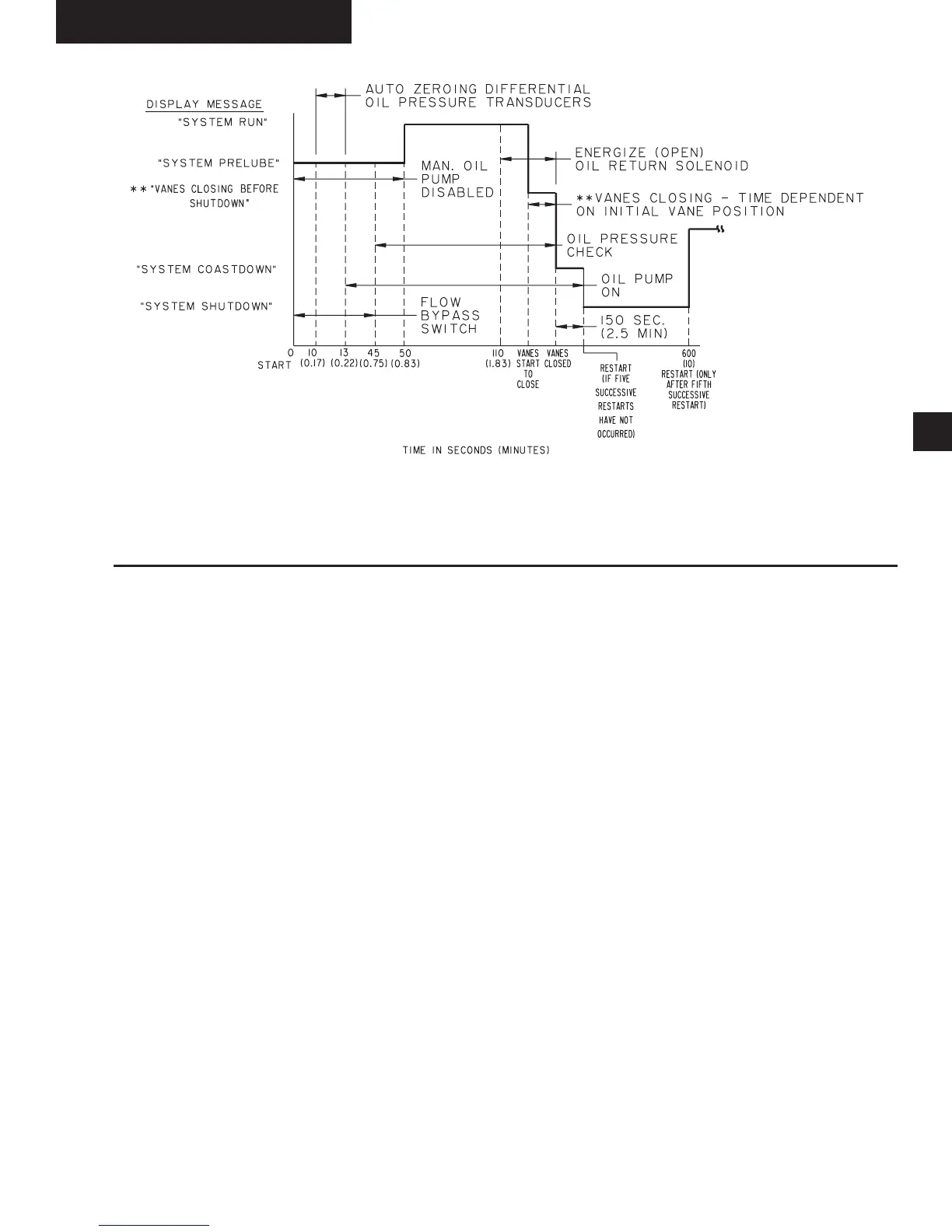

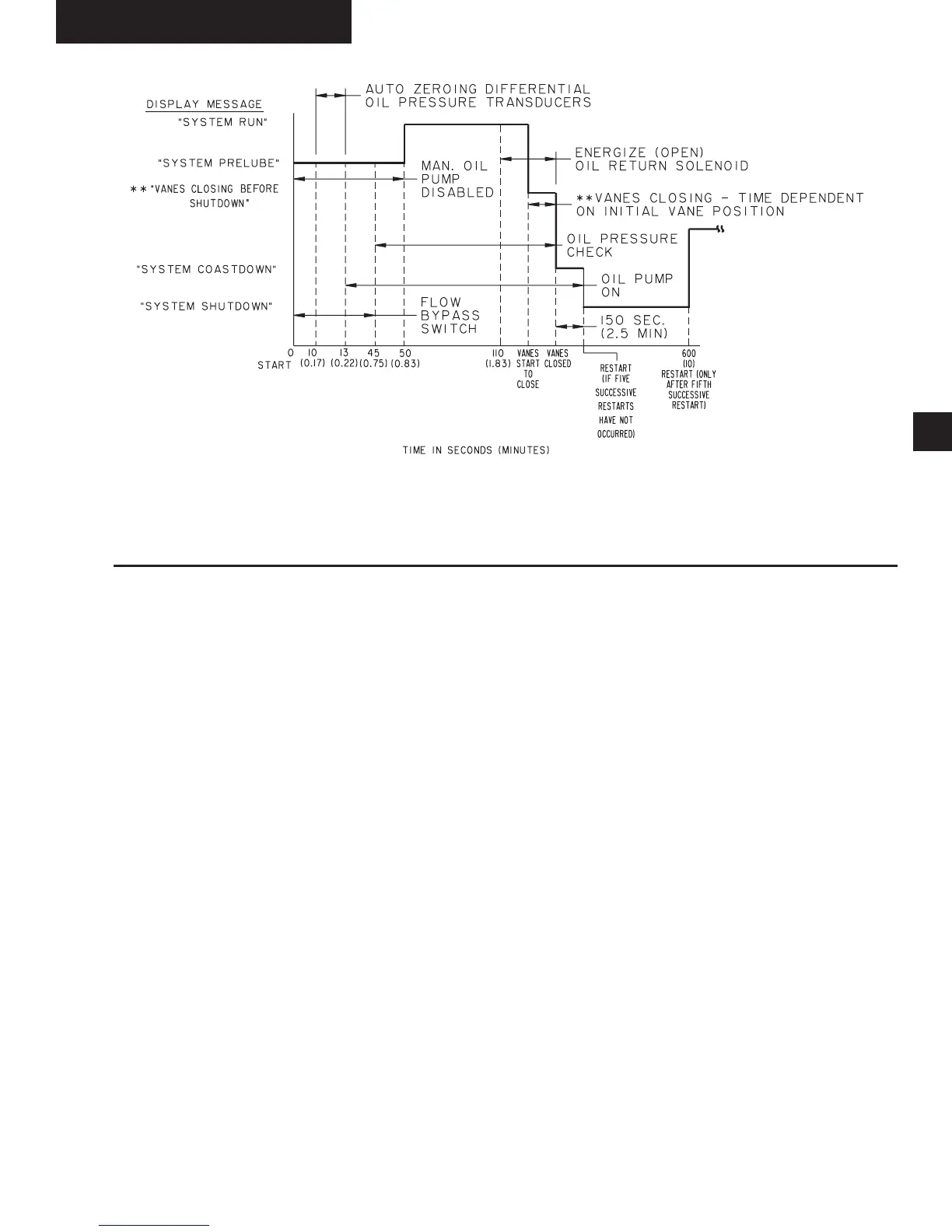

FIG. 5 – CHILLER STARTING SEQUENCE & SHUTDOWN SEQUENCE

(VARIABLE SPEED DRIVE)

LD04130

CHILLER OPERATION

After the compressor reaches its operating speed, the

Prerotation Vanes will begin to open under the control

of the Microprocessor Board which senses the leaving

chilled liquid temperature. The unit capacity will vary to

maintain the leaving CHILLED LIQUID TEM PER A-

TURE setpoint. The Prerotation Vanes are mod u lat ed

by an actuator un der the control of the Mi cro pro ces sor

Board. The vane control routine employs pro por tion al

plus de riv a tive (rate) control action. A drop in chilled

liquid tem per a ture will cause the actuator to close the

Prerotation Vanes to de crease chiller ca pac i ty. When

the chilled liq uid tem per a ture rises, the ac tu a tor will

open the Prerotation Vanes to increase the ca pac i ty of

the chiller.

However, the current draw (amperes) by the com pres sor

motor cannot exceed the setting of the % CUR RENT

LIM IT at any time during the unit operation, since the

Microcomputer Control Center 40 to 100% three-phase

peak current limit software function, plus the 3-phase

100% solid state overload current limiter (CM-2), on

Electro-Mechanical Starter applications, or the Solid

State Starter current Limit function will over ride the

tem per a ture control function and prevent the Pre rota tion

Vanes from opening beyond the % CUR RENT LIMIT

setting.

** NOT FOR ALL SHUTDOWNS. REFER TO “DISPLAY MES-

SAG ES” SECTION OF THIS MANUAL.

System Op er at ing Pro ce dures

If the load continues to decrease, after the Prerotation Vanes

are entirely closed, the chiller will be shut down by the

Leaving Chilled Liquid – Low Temperature Con trol.

CONDENSER WATER TEMPERATURE CON TROL

The YORK MaxE

TM

chiller is designed to use less power

by taking advantage of lower than design tem per a tures

that are naturally produced by cooling tow ers through out

the operating year. Exact control of con dens er water

such as a cooling tower bypass, is not nec es sary for

most installations. The chiller requires only that the

minimum condenser water temperature be no lower

than the value

determined by referring to the for mu la below:

where:

ECWT = Entering Condensing Water Temperature

LCWT = Leaving Chilled Water Temperature

C Range = Condensing water temperature range at the

given load condition.

Min. ECWT = LCWT – C RANGE + 17ºF

Min. ECWT = LCWT – C RANGE + 9.4ºC

Loading...

Loading...