FORM 160.73-O2 (605)

9

YORK INTERNATIONAL

CHECKING THE OIL LEVEL

IN THE OIL RESERVOIR

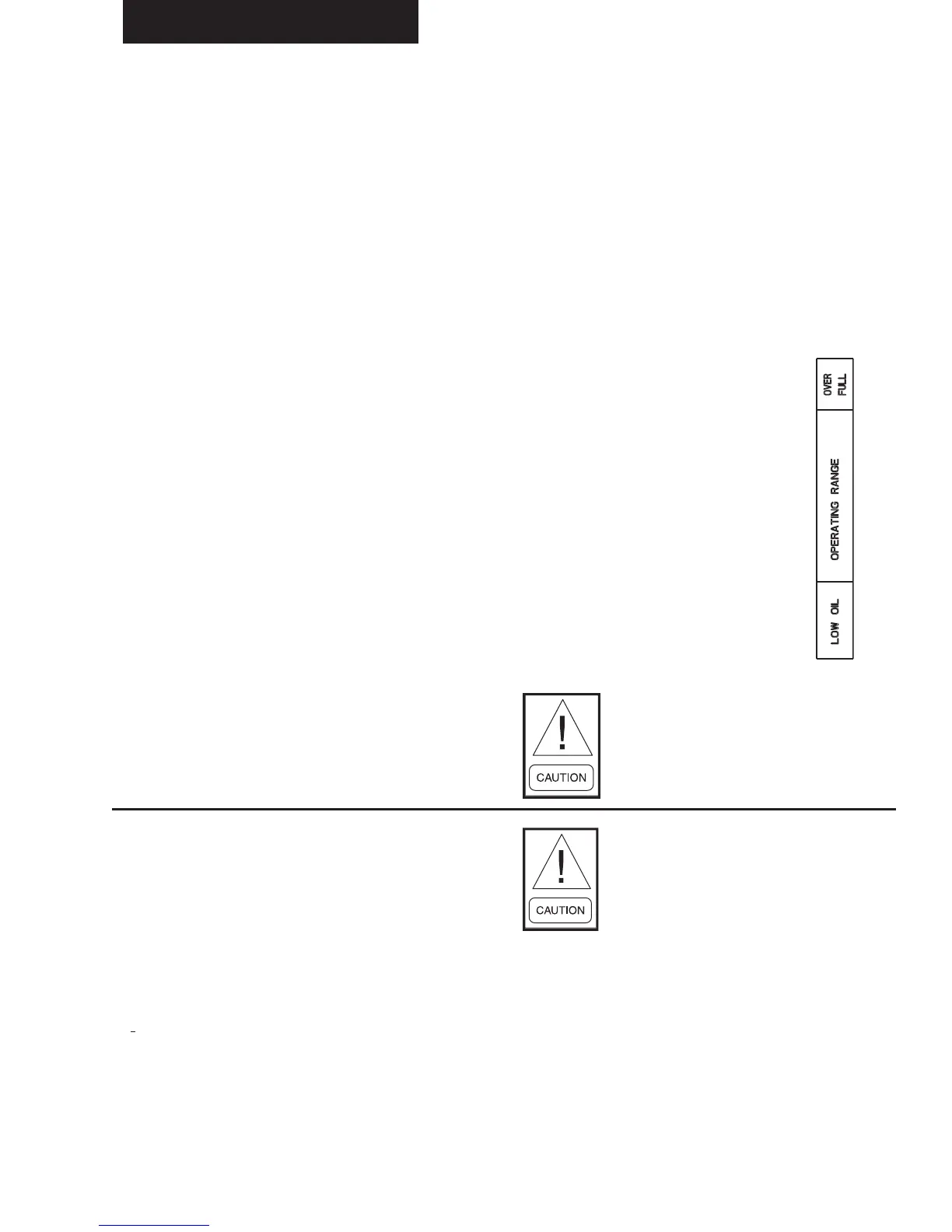

Proper operating oil level – During operation, the oil

level should fall to the “Operating Range” identifi ed on

the vertical oil level indicator label. See Figure 3.

• If the oil level during operation is in the “Over

Full” region of the oil level indicator, oil should be

removed from the oil reservoir, This reduces the oil

level to the “Operating Range”.

• If the oil level during operation is in

the “Low Oil” region of the oil level

indicator, oil should be added to the

oil reservoir. (See “Oil Charging Pro-

cedure”, page 22)

START-UP PROCEDURE

Pre-Starting

Prior to starting the chiller, observe the OptiView

Control Center. Make sure the display reads SYSTEM

READY TO START.

To pre-start the chiller, use the following procedure:

1. Oil Heater – The oil heater must be energized for

12 hours prior to starting the chiller.

2. Prior to start, the clock must be programmed for the

proper day and time. Any setpoints which are de sired

to be changed may be programmed. All Control Cen-

ter setpoints should be pro grammed before the chiller

is started. (Refer to Form 160.54-O1).

Vent any air from the chiller water

boxes prior to starting the water

pumps. Failure to do so will result in

pass baffl e damage.

START-UP

1. If the chilled water pump is manually operated, start

the pump. The Control Center will not allow the

chill er to start unless chilled liquid fl ow is es tab lished

through the unit. (A fi eld supplied chilled wa ter fl ow

switch is required.) If the chilled liquid pump is wired

to the Microcomputer Control Cen ter the pump will

au to mat i cal ly start, therefore, this step is not neces-

sary.

System Op er at ing Pro ce dures

SECTION 2

SYSTEM OPERATING PROCEDURES

OIL HEATERS

If the oil heater is de-energized during a shut down pe ri od,

it must be energized for 12 hours prior to start ing com-

pres sor, or remove all oil and re charge com pres sor with

new oil. (See “Oil Charging Pro ce dure”, page 22.)

OIL HEATER OPERATION

The oil heater operation is controlled by the OptiView™

Control Center. The heater is turned on and off to main-

tain the oil temperature differential to a val ue 50°F

(27.8°C) above the condenser saturation tem per a ture.

This is the target value and if the oil tem per a ture falls to

4°F (2.2°C) or more below the target, the heater is turned

on. It is turned off when the oil temperature increases to

3°F (1.7°C) above the target value.

If the target value is greater than 160°F (71°C), the tar get

de faults to 160°F (71°C). If the target value is less than

110°F (43.3°C), it defaults to 110°F (43.3°C).

To prevent over heat ing of the oil in the event of a con-

trol center component fail ure, the oil heat er ther mo stat

(1HTR) is set to open at 180°F (82°C).

FIG. 3 – OIL LEVEL INDICATOR

LD08647

Comply with EPA and Local reg u -

la tions when re mov ing or disposing

of Re frig er a tion System oil!

Loading...

Loading...