17

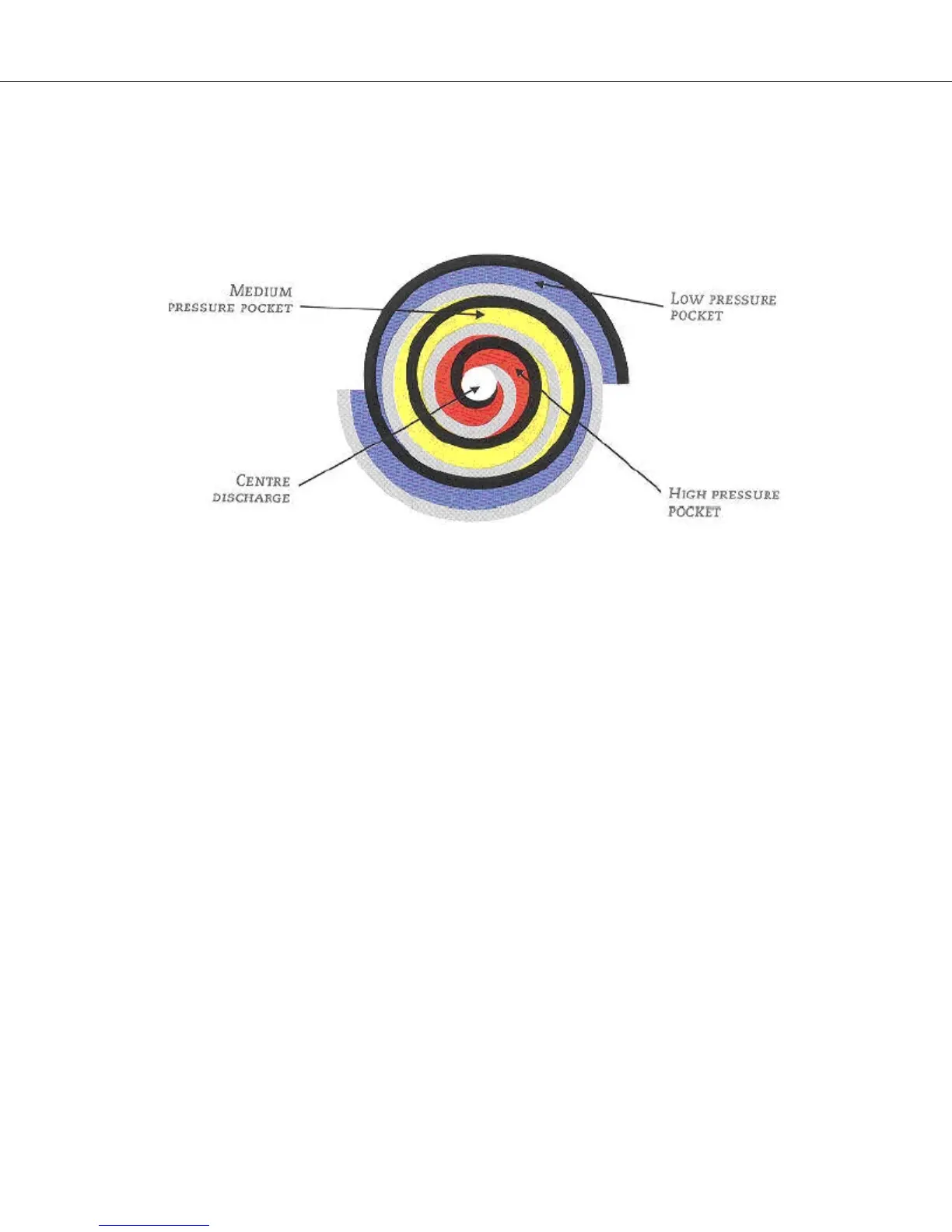

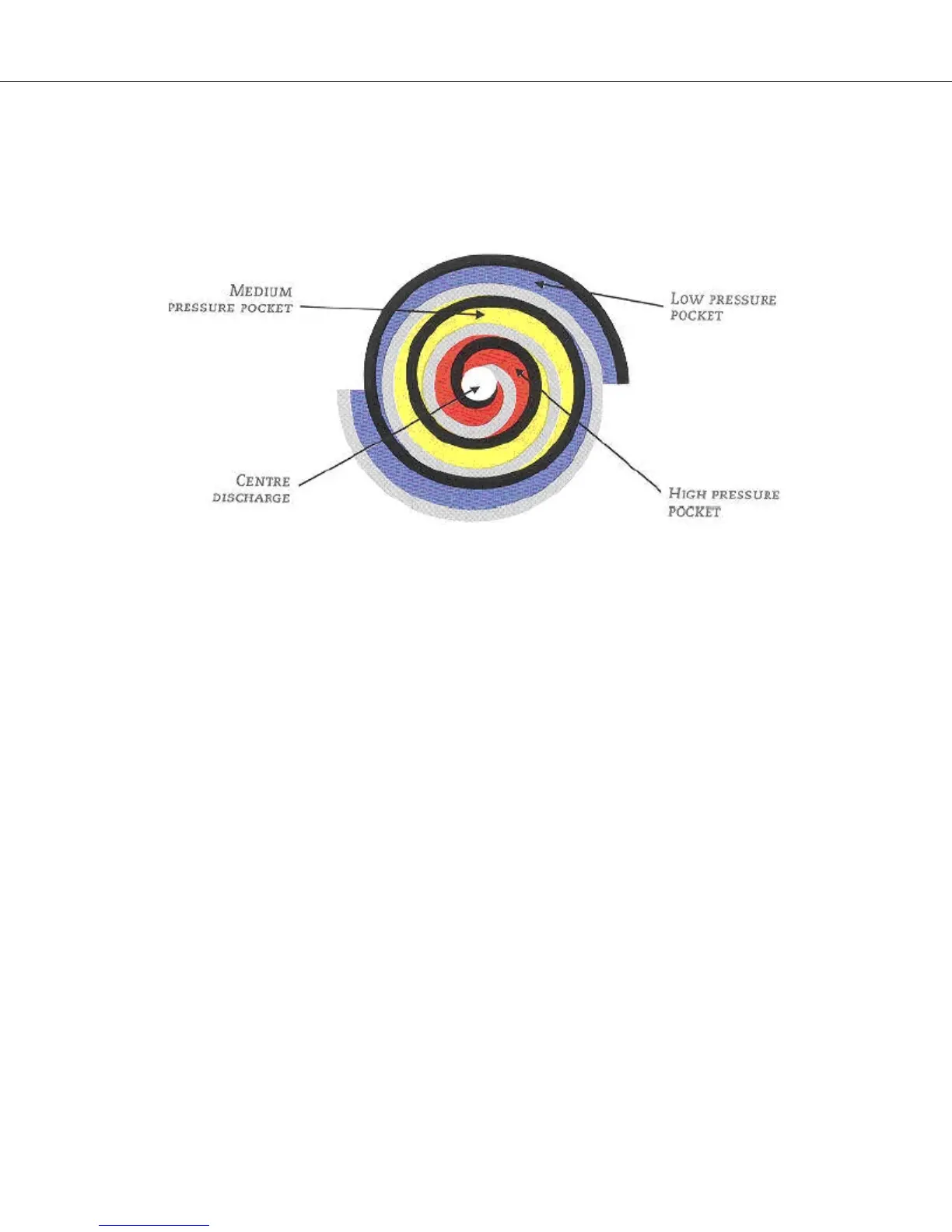

Refrigerant enters the compressor at the suction connection and flows around the motor’s housing and enters at the

bottom side through the openings.

Oil droplets separate from the refrigerant and fall into the oil sump.

All suction refrigerant passes through the electrical motor, ensuring full motor cooling.

After that the refrigerant enters the scroll elements.

3.3.2 Condenser Coil

Condenser coils are corrugated fin and tube type; constructed of seamless 3/8" diameter inner grooved copper tubes,

mechanically bonded to enhanced louvered aluminum fins for maximum heat transfer efficiency. As the fins have full self

spacing collars which completely cover each tube. The staggered tube design improves the thermal efficiency. End

plates support sheets are heavy gauge galvanized steel, formed to provide structural strength. Each coil is pressure

tested in the factory at not less than 450 psi air pressure. Finally the coils are coated with thermo guard coating for

protection against seashore salty and corrosive environments.

3.3.3 Condenser Fan

Condenser fans are constructed of die cast aluminum blades/hubs with direct driven motors. All fans are statically and

dynamically balanced to operate at minimum noise and vibration. Fan blades are designed with appropriate pitch angle

which result in maximum airflow through the condenser coil.

3.3.4 Condenser Fan Motor

Condenser fans, the impeller and motors are so constructed to form an integral unit. All fan motors shall be three phase

with class ‘’F’’ winding insulation and ball bearings for high ambient application. These fan motors are of totally enclosed

air over type (TEAO) with inherent thermal protection of automatic reset type & specially designed for outdoor applica-

tions.

3.3.5 Evaporator Coil

Coils are made with corrugated fins and seamless ½’’ diameter copper tubes mechanically bounded enhanced fins

enable maximum heat transfer efficiency. Evaporator is tested in the factory at 300 PSI air pressure. Finally the coils are

coated with thermo guard coating for protection against seashore salty and corrosive environments. Coils conform to ARI

standard 410.

3.3.6 Evaporator Fan

Heavy-duty high pressure backward radial fan is capable of supplying required airflow & static pressure. The fan dis-

charge outlet can be connected to a flexible pre-conditioned delivery hose (supplied along with unit). Flexible duct is

constructed by two-ply, abrasion resistant fabrics or PVC coated fabrics and is stowed inside the storage box, when not

in use.

Loading...

Loading...