Page - 20/90 AF9ZP0BA - EPS-ACW REACH TRUCK - User Manual

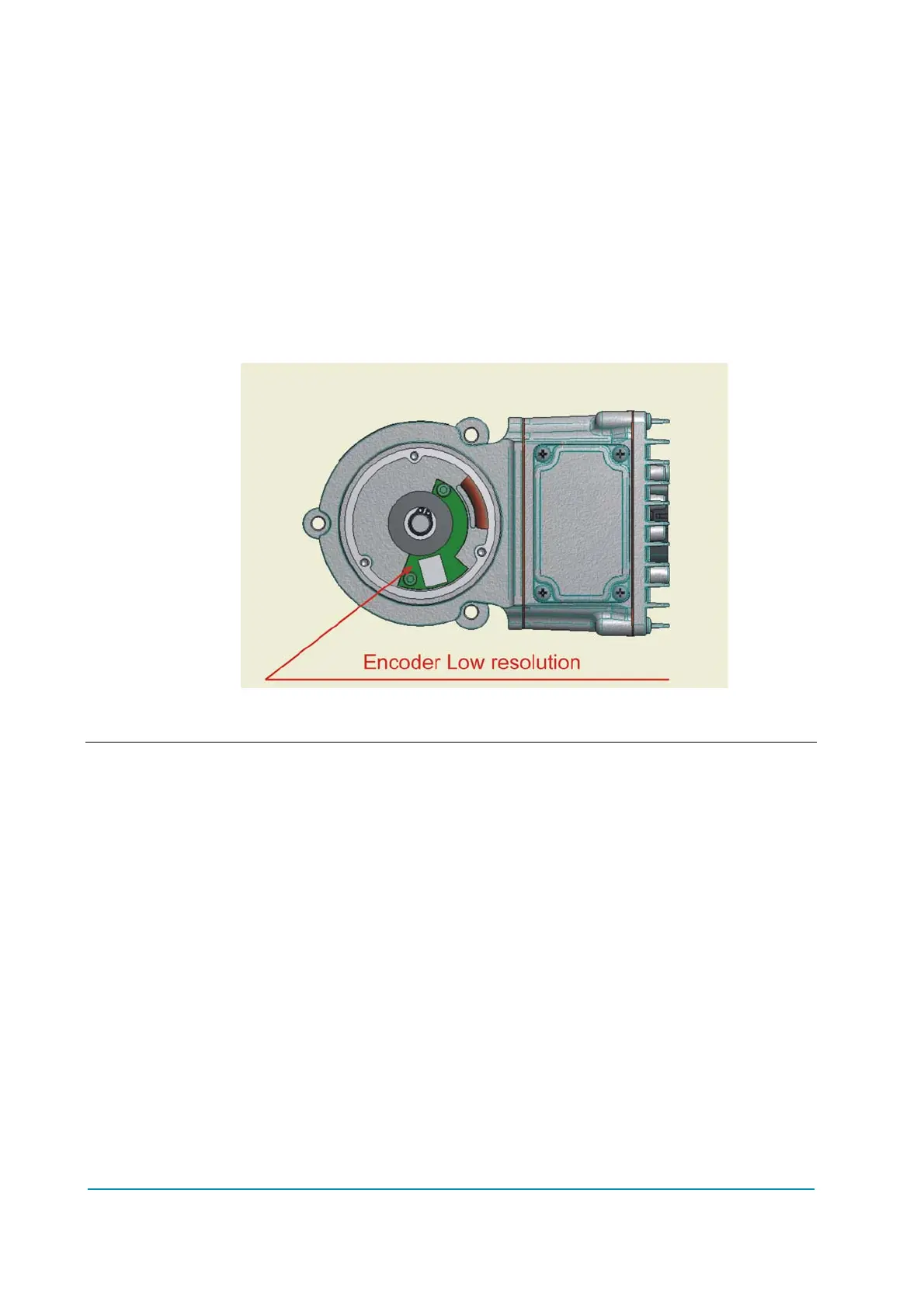

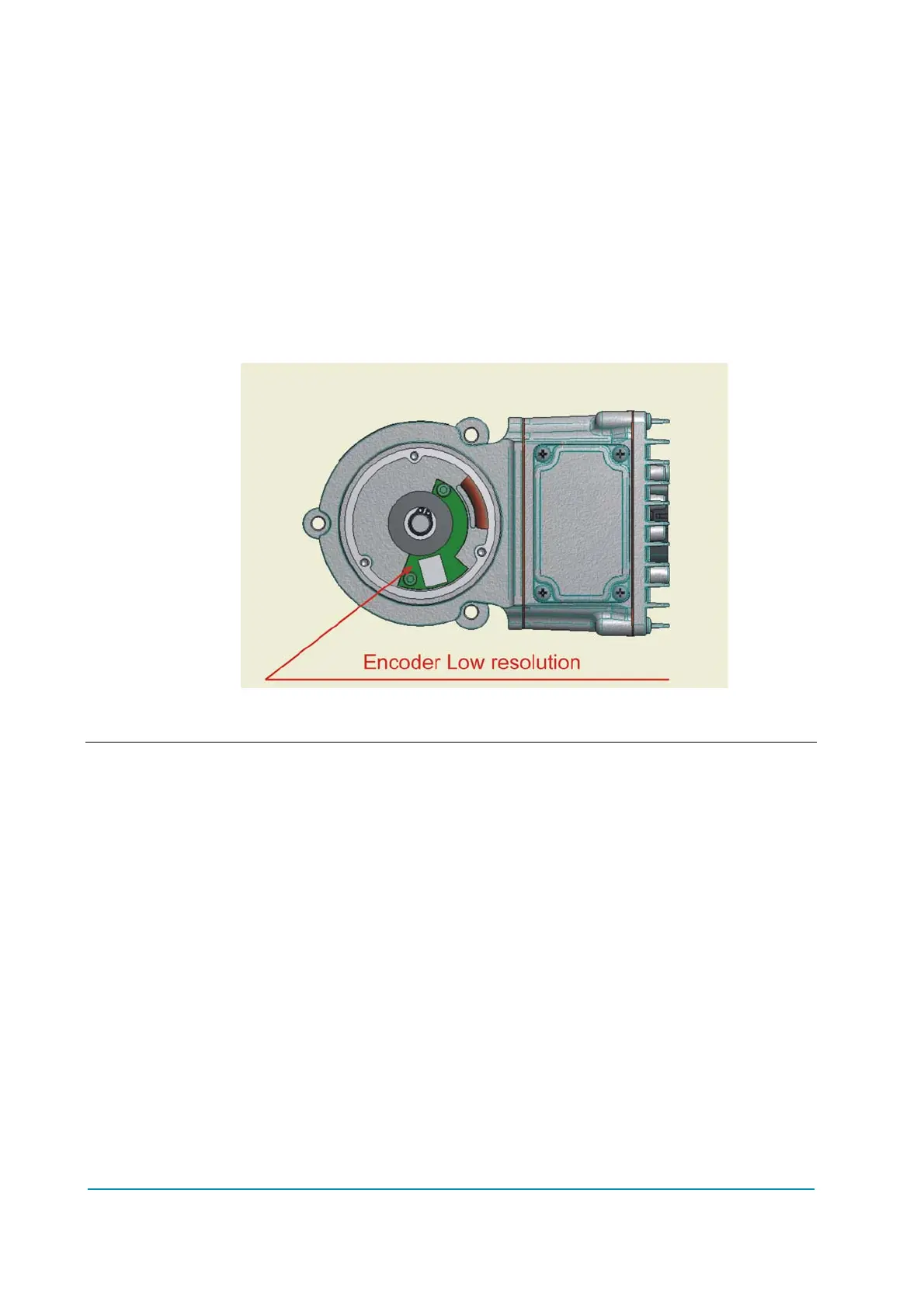

9.5.1.3 Feedback Encoder

One big advantage of our epsacW controller is that it can work with a cost-

effective very low-resolution encoder. It consists of a multipole magnet (4 pole

pairs) engaging two digital hall sensors leading to a resolution of 4pulses/rev.

That is more than enough for the angle measurement: in fact, with a total

reduction ratio of 1:200 and a 4 pulses/revs resolution, we have 1600 events

(encoder transitions) within 180° of the steered angle. So the angle

measurement is determined with quanta of 180/1600=0.112 degrees.

Following this statement, we have developed, together with the Zapi AC-motors-

manufacturer, a 4 pulses/rev discrete encoder. It is an external device (not

integrated in the ball bearing) mounted in the backside of the motor (see Figure

9.5.1.3-1). The advantages of this solution are both, money saving and effective

time saving in case of encoder replacement.

Figure 9.5.1.3-1

4 Note: The SW must know the encoder resolution together with the poles-pair

number. The encoder resolution and the motor pole pairs (the controller can

handle), will be specified in the headline of the handset showing something like:

EPSWSM 1Q NA4.98

That means:

EPSW = EpsacW steering controller

S= Open Loop Mode (Stepper motor).

M= Master Microcontroller

X= type of sensor in the TFD

1= poles pair number

Q= 4 pulses/rev encoder

NA= SW release type Nacco

4.98= SW release number 4.98

The command configuration is specified through the first two letter after EPS in

the following list:

WS= Open Loop (Stepper Motor) for Warehouse Trucks

Loading...

Loading...