45

Using the Movable Black Mark Sensor

9/30/2014 GT800™ Thermal Transfer Printer User Guide P1032729-003Rev. A

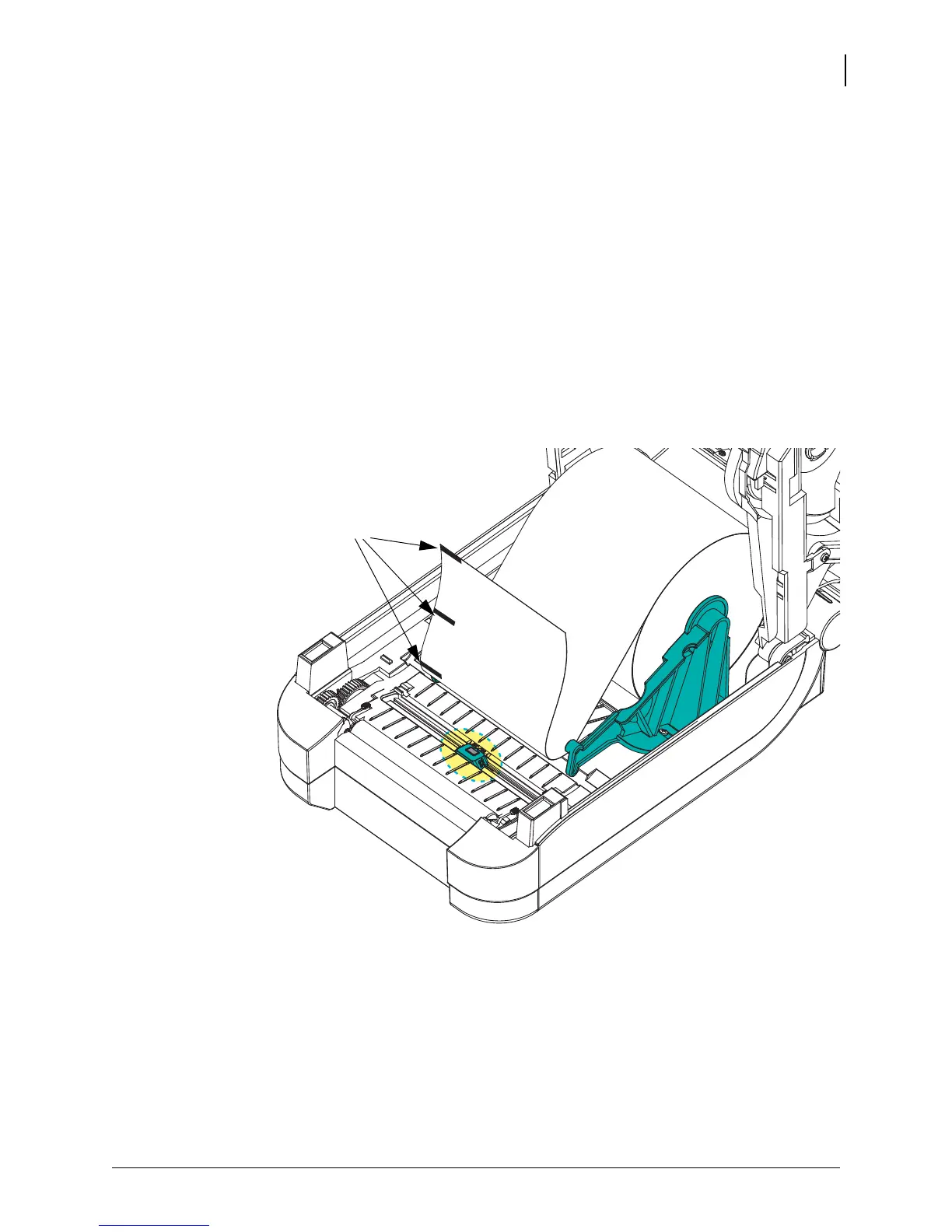

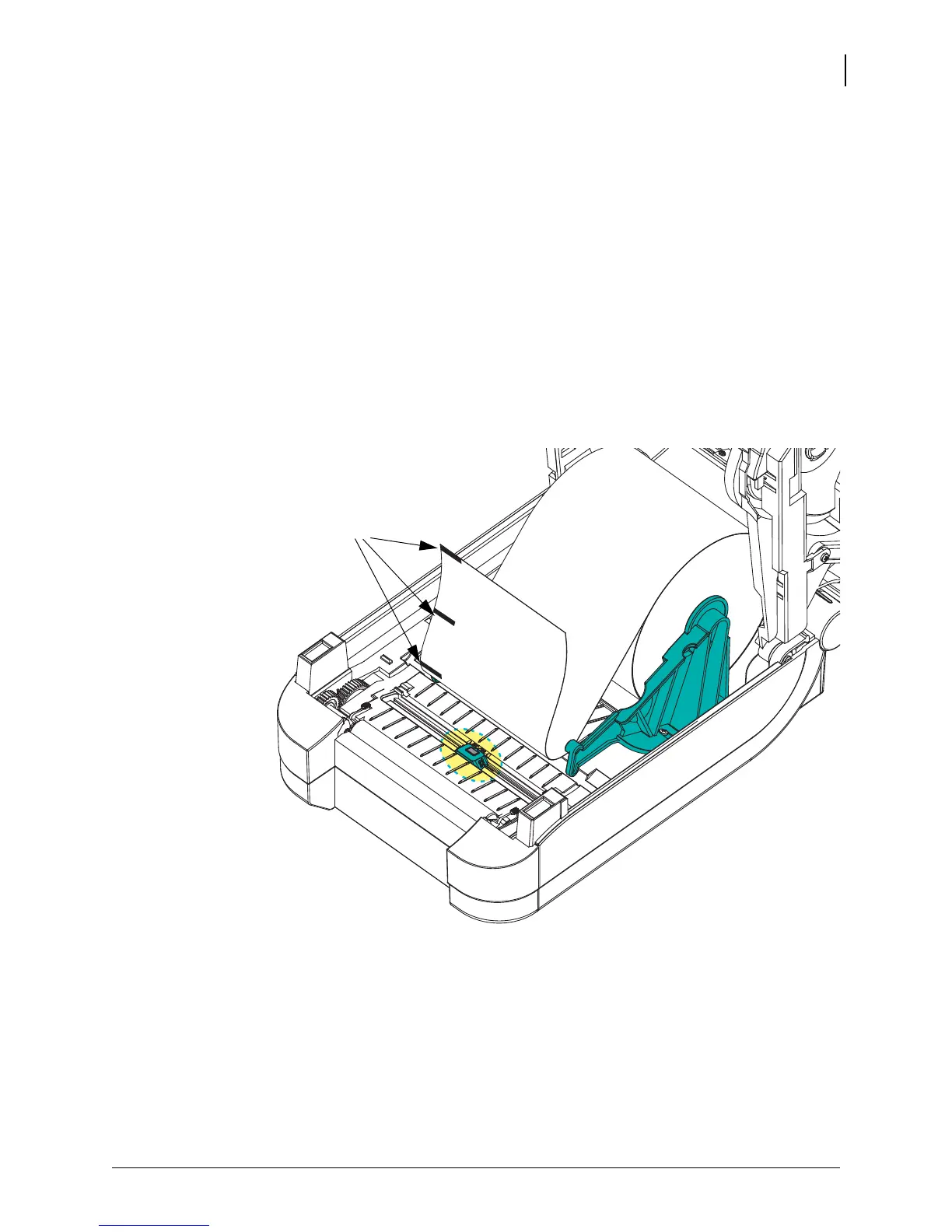

Adjusting the Movable Sensor for Black Marks or Notches

The black mark sensor looks for non-reflective surfaces such as black marks, black lines,

notches or holes in the media which do not reflect the sensor’s beam back to the sensor’s

detector. The sensor light and it’s black mark detector are next to each other under the sensor

cover (dark plastic cover is translucent to the sensor’s non-visible light).

Aligning the movable sensor’s alignment arrow to the middle of the black mark or notch in the

underside of the media. Sensor alignment should be set as far as possible from the edge of

media but where 100% of the sensor window is covered by the mark. When printing, the

media can move from side to side ±1mm (due to media variations and edge damage due to

handling). Notches cut into the side of the media can also become damaged.

Load the media. Before closing the printer, adjust the movable black mark sensor as follows:

1. Flip the media back over the roll to expose the black marks or notches on the backside

(non printing side) of the media.

Loading...

Loading...