MAIN MOVING SYSTEM EM -45

DISASSEMBLY E A7E6C0F

1. Remove the timing belt, front case, flywheel, cylinder

head assembly and oil pan. For details, refer to the

respective chapters.

2. Remove the rear plate and the rear oil seal.

3. Remove

the connecting rod caps.

4. Remove the main bearing caps and remove the crank-

shaft.

5. Remove the crankshaft position sensor wheel.

CAUTI

ON

Mark the main bearing caps to permit reassembly

in the original position and direction.

INSPE

CTION

E76DB219

CRANKSHAFT

1. Check the crankshaft journals and pins for damage,

uneven wear, and cracks. Also check oil holes for

clogging. Correct or replace any defective part.

2. Inspe

ct the crankshaft journal for taper and out - of -

roun

d.

Standard value

Crankshaft journal O.D : 50 mm (1.9685 in.)

Crankshaft pin O.D : 45 mm (1.7717 in.)

Crankshaft journal, pin out-of-roundness and taper :

0.005 mm (0.0002 in.) or less

MAIN BEARINGS AND CONNE CTING ROD

BEARINGS

Visually inspect each bearing for peeling, melting, seizure,

and improper contact. Replace the defective bearings.

OIL CLEARANCE MEASUREMENT

1. Measure the diameter of the crankshaft journal and

pin.

2. Measure the diameter of the crankshaft bore and con-

necting rod bore.

3. Measure the thickness of the crankshaft bearing and

connecting rod bearing.

4. Measure the clearance by the value that subtract the

diameter of journal and pin and the thickness of bear-

ing from the diameter of bore.

Connecting rod bearing oil clearance :

0.018 ~ 0.036 mm (0.0007 ~ 0.0014 in.)

Crankshaft main bearing oil clearance

NO. 1,2,4,5 : 0.022 ~ 0.040 mm (0.0009 ~ 0.0018 in.)

NO.3 : 0.028 ~ 0.046 mm (0.0011 ~ 0.0018 in.)

OIL SEAL

Check front and rear oil seals for damage or wear. Replace

any seal that is defective.

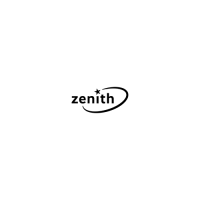

CRANKSHAFT SENSOR WHEEL

1. Remove the sensor wheel.

2. Chec k the sensor wheel for damage, cracks and wear,

and replace if necessary.

3. Chec k the clearance between the sensor wheel and

the crank position sensor with a depth gage.

Standard value

Clearance between sensor wheel and crank

position sensor :

0.5 ~ 1.1 mm (0.020 ~ 0.043 in.)

EDDA028C

NOTE

1. Measure the depth of the top of sensor wheel

tooth and the cylinder block mounting block.

2. Measure the difference between sensor length

and depth.

3. Sensor length is the distance between the end of

the sensor and the inner point of the contacting

face.

ZENITH POWER PRODUCTS - 416

Loading...

Loading...