MAIN MOVING SYSTEM EM -47

REASSEMBLY E0ABCAB2

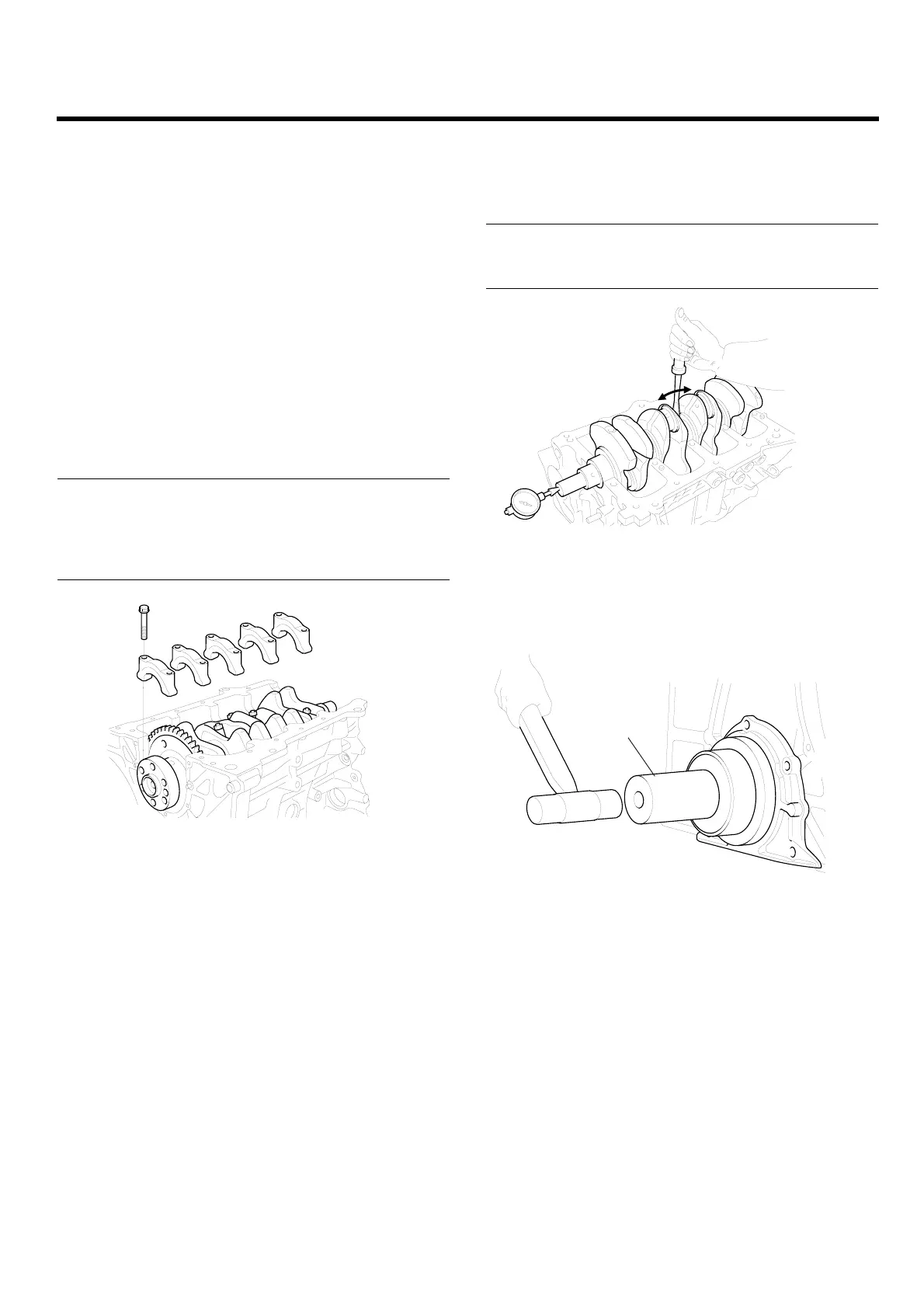

1. Install the upper main bearing inserts in the cylinder

block.

When reusing the main bea rings, remember to in-

stall them by referring to the location marks made

at the time of disassembly.

2. Install the crankshaft. Apply engine oil to the journals.

3. Instal

l bearing caps and tighten cap bolts to the spec-

ified

torque in the following sequence; center, No.2,

No.4,

front, and rear caps.

Cap bo

lts should be tightened evenly in 2 to 3 stages

befor

e they are tightened to the specified torque.

The ca

ps should be installed with the arrow mark di-

recte

d toward the crank pulley side of engine. Cap

numbe

rs must be correct.

Tightening torque

Main bearing cap bolt :

55 ~ 60 Nm (550 ~ 600 kg.cm, 41 ~ 44 lb.ft)

Connecting rod cap bolt :

32 ~ 35 Nm (320 ~ 350 kg.cm, 24 ~ 26 lb.ft)

EDKE151A

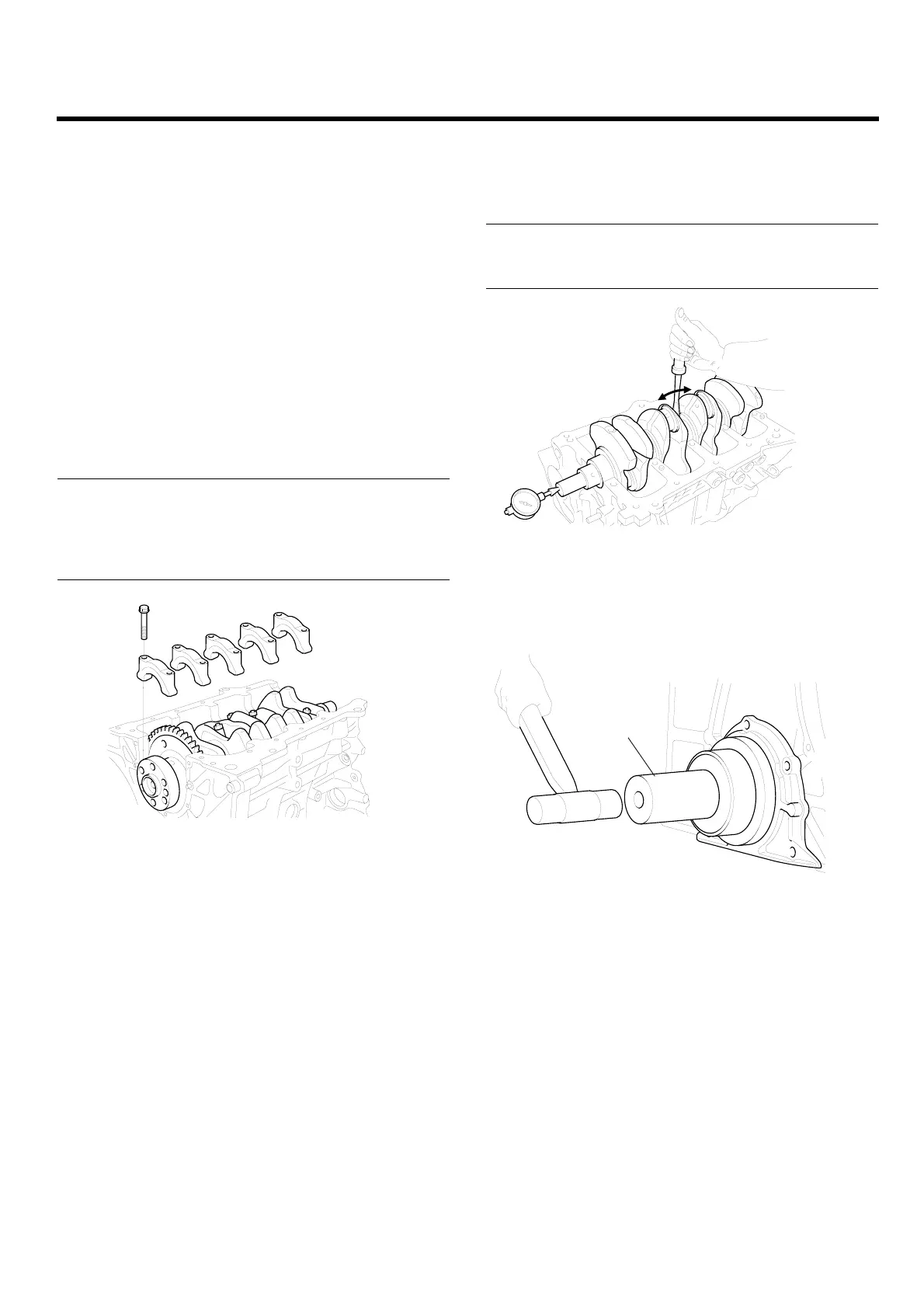

4. Mak e certain that the crankshaft turns freely and has

the proper clearance between the center main bear-

ing thrust flange and the connecting rod big end bear-

ing.

Standard value

Crankshaft end play :

0.05 ~ 0.175 mm (0.0019 ~ 0.0068 in.)

ECKD001B

5. Install the oil seal in the crankshaft rear oil seal case.

Use the Special Tool, Crankshaft Rear Oil Seal In-

staller (09231 - 21000) as shown. Press fit the oil seal

all the way in, being careful not to misalign it.

09231-21000

ECKD326A

6. Install the rear plate and tighten the bolts.

7. Install the connecting rod caps.

8. Install the flywheel, front case, oil pan and timing belt.

For further details, refer to the respective chapters.

ZENITH POWER PRODUCTS - 416

Loading...

Loading...