EM -56 ENGINE DOHC

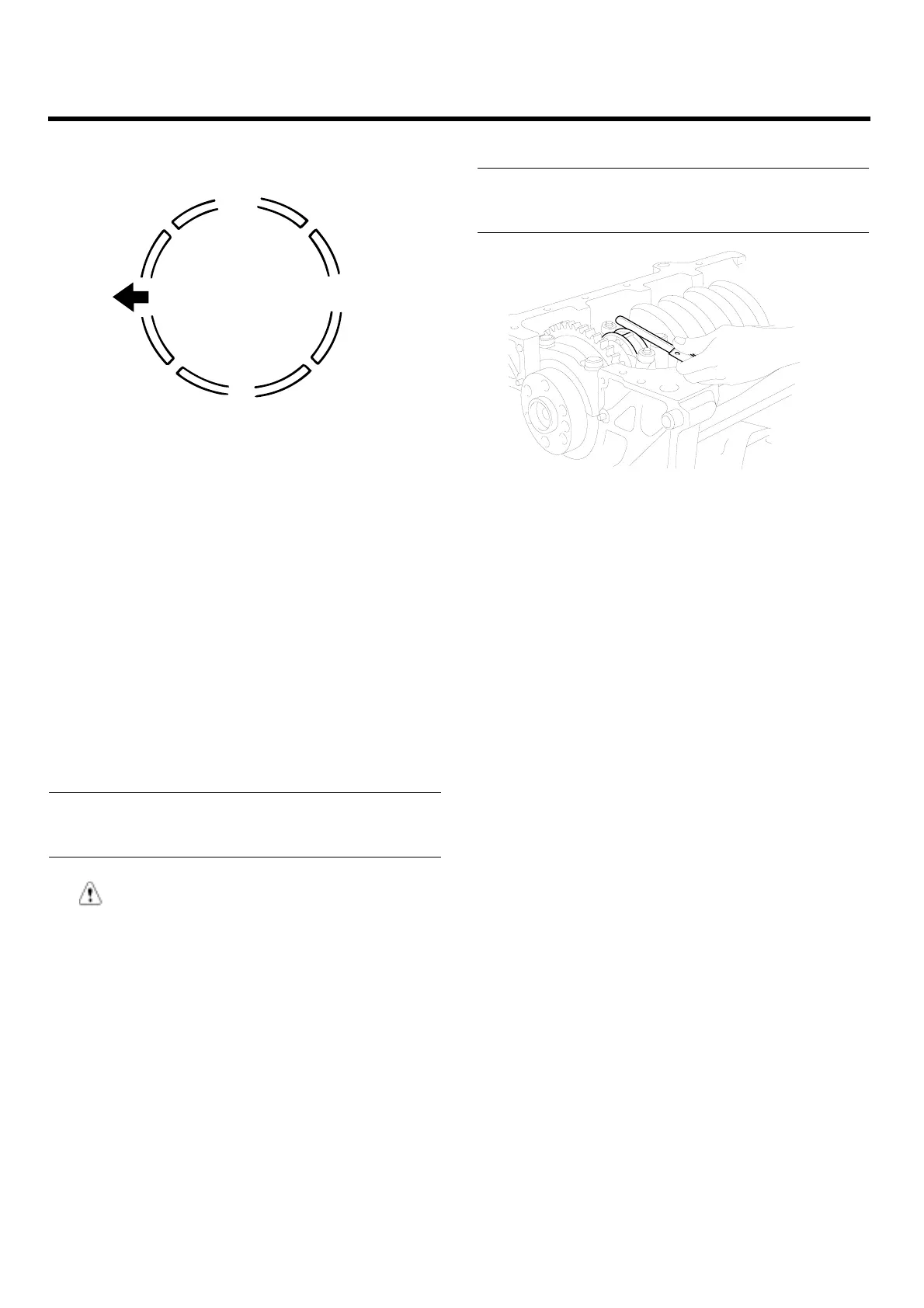

8. Hold the piston rings firmly with a piston ring compres-

sor as they are inserted into cylinder.

Gap of upper

side rail

No.1 ring

gap

Front of

engine

No.2 ring gap

and spacer

expander gap

Gap of lower

side rail

ECA9380D

9. Install the upper main bearings in the cylinder block.

10. Install the lower main bearings in the main bearing

caps.

11. Make sure that the front mark of the piston and the

front mark (identification mark) of the connecting rod

are directed toward the front of the engine.

12. When a new connecting rod is installed, make sure

that the notches for holding the bearing in place are

on the same side.

13. When assembling, bolts should be fastened by the

angle - torque controlled method as the following.

1) Apply oil to the thread of nuts and spot areas.

2) Tighten the connecting rod bolt.

Tightening torque

Connecting rod cap nut :

32 ~ 35 Nm (320 ~ 350 kg.cm, 24 ~ 26 lb.ft)

CAUTION

After removing the connecting rod bolt, do not

use if again.

When using a new bolt, do not tighten the bolt

more than 3 times.

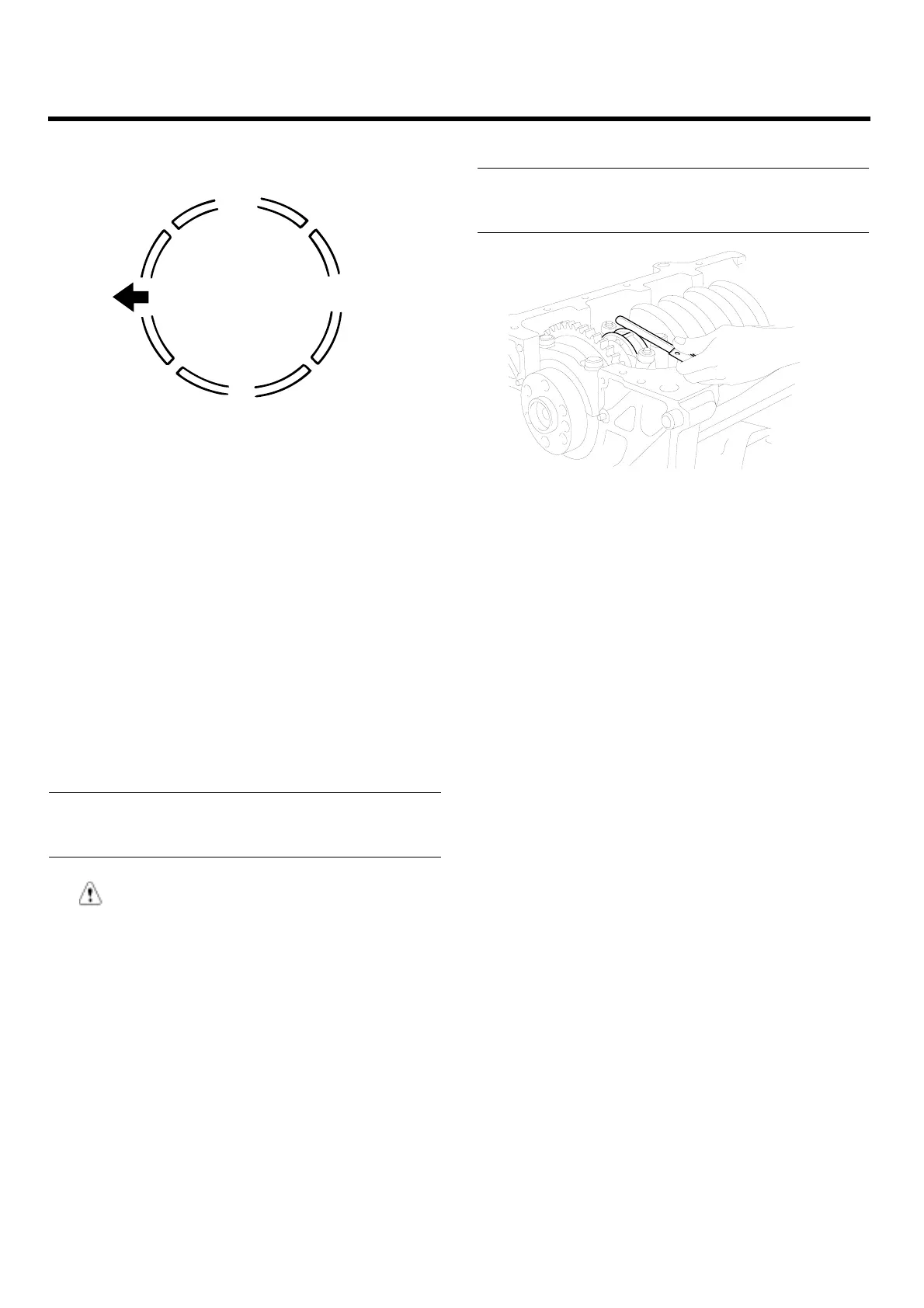

14. Check the connecting rod side clearance.

Connecting rod side clearance

Standard : 0.10 ~ 0.25 mm (0.0039 ~ 0.0098 in.)

Limit : 0.4 mm (0.0157 in.)

EDKD14 5A

15. Install the oil screen.

16. Install the oil pan.

17. Install the cylinder head.

ZENITH POWER PRODUCTS - 416

Loading...

Loading...