ENGINE BLOCK EM -73

DISASSEMBLY E E96372F

1. Remove the timing belt, cylinder head, front case, fly-

wheel, pistons and crankshaft.

2. Remove the oil pressure switch.

Adapter

EDDA008A

INSPECTION EBADEC 3 C

1. Check the engine block for scores, rust and corrosion.

Also check for cracks or any other defects. Replace

the block if defective.

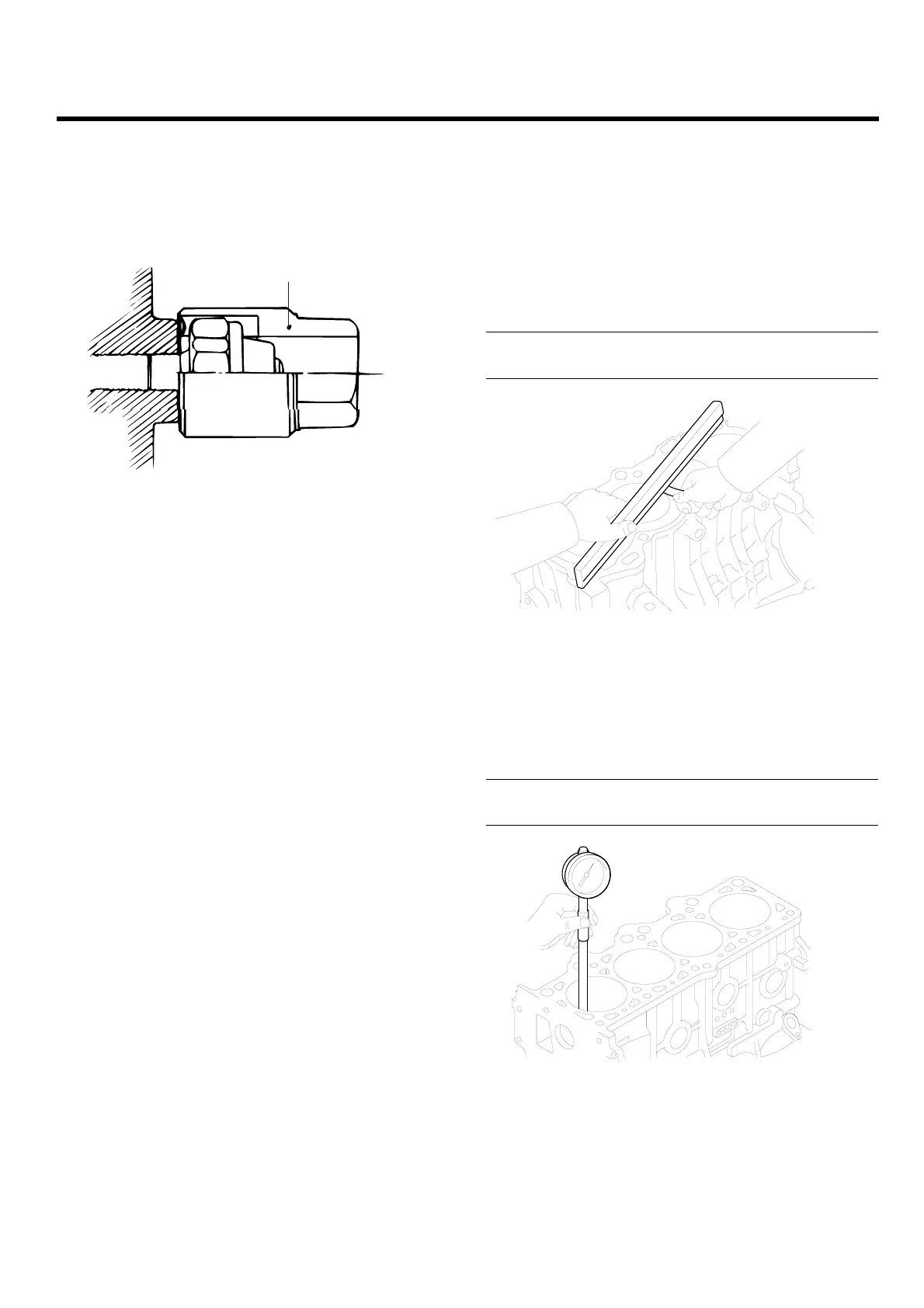

2. Using a straight edge and feeler gauge, check the

top surface of the block for warpage. Make sure that

the surface is free from gasket chips or other foreign

material.

Standard : 0.03 mm (0.0012 in.) or less

Limit : 0.06 mm (0.0024 in.) or less

ECKD00 1L

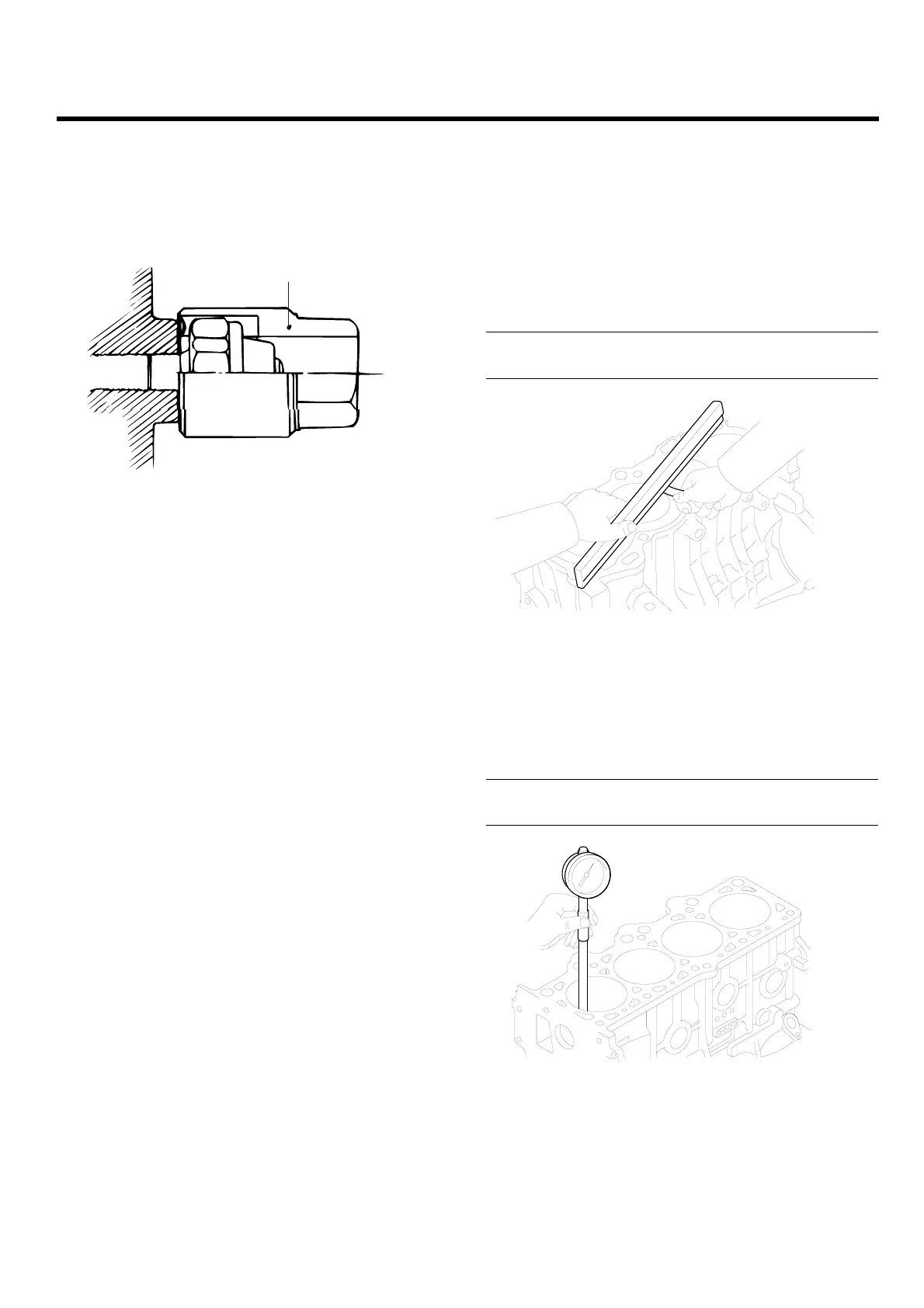

3. Measure the cylinder bore with a cylinder gauge at

three levels in the direction of A and B. If the cylinder

bores show more than the specified out-of-round

or taper or if the cylinder walls are badly scuffed or

scored, the cylinder block should be rebored and

honed. Oversize pistons and rings must be fitted.

Cylinder I.D : 76.5 ~ 76.53 mm (3.0118 ~ 3.0130 in.)

Cylinder I.D taper : 0.01 mm (0.0004 in.) or less

ECKD318A

ZENITH POWER PRODUCTS - 416

Loading...

Loading...