Maintenance and Installation Instructions Edition 11.07.2006 13 of 30

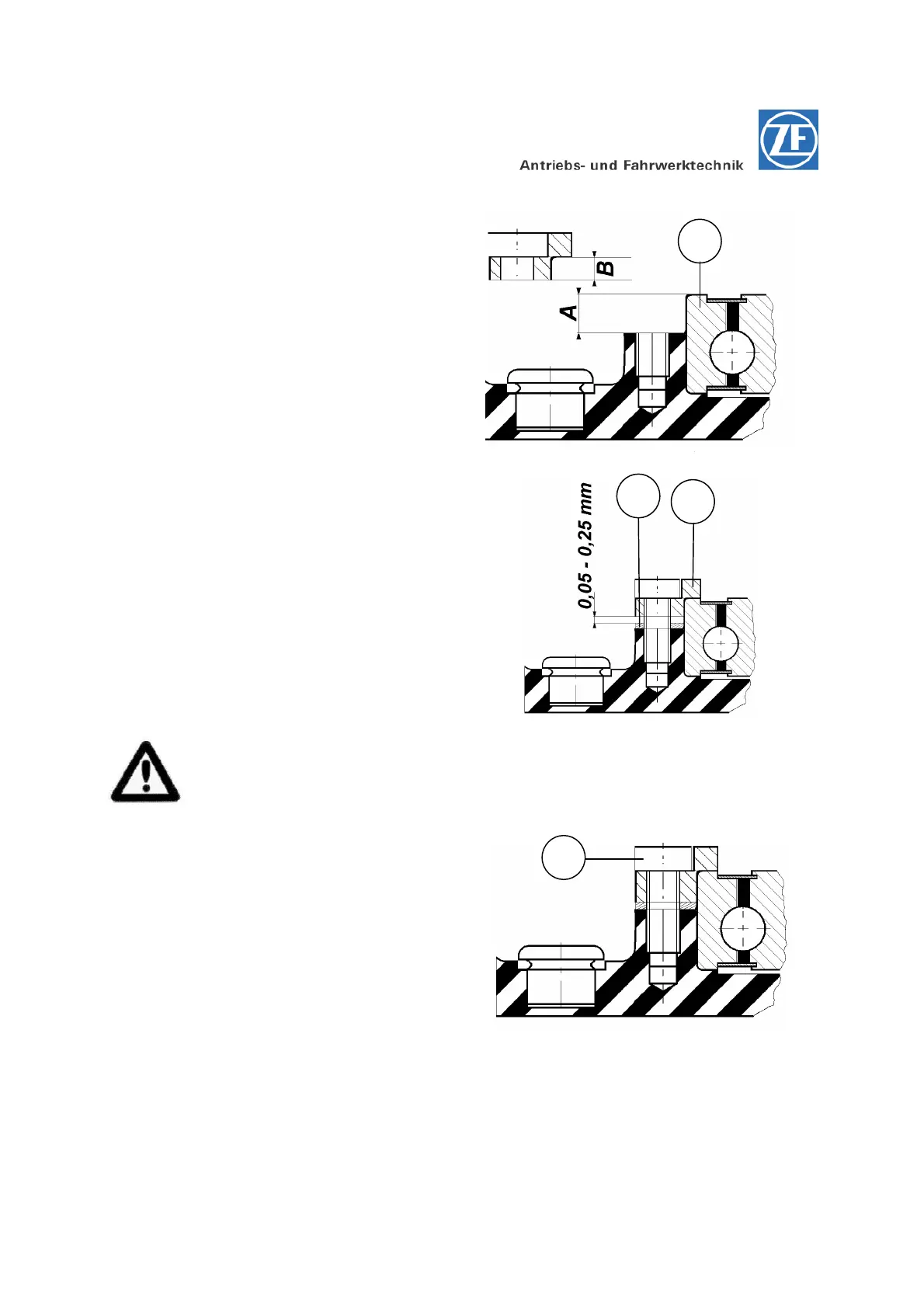

Mounting of the pivoted bogie bearing with holding ring GK 40

a) Press the pivoted bogie bearing (Item 01)

evenly into the transmission top section

until contact is obtained.

b) Determine the Dim. A and B.

Prior to bolting

Figure 06

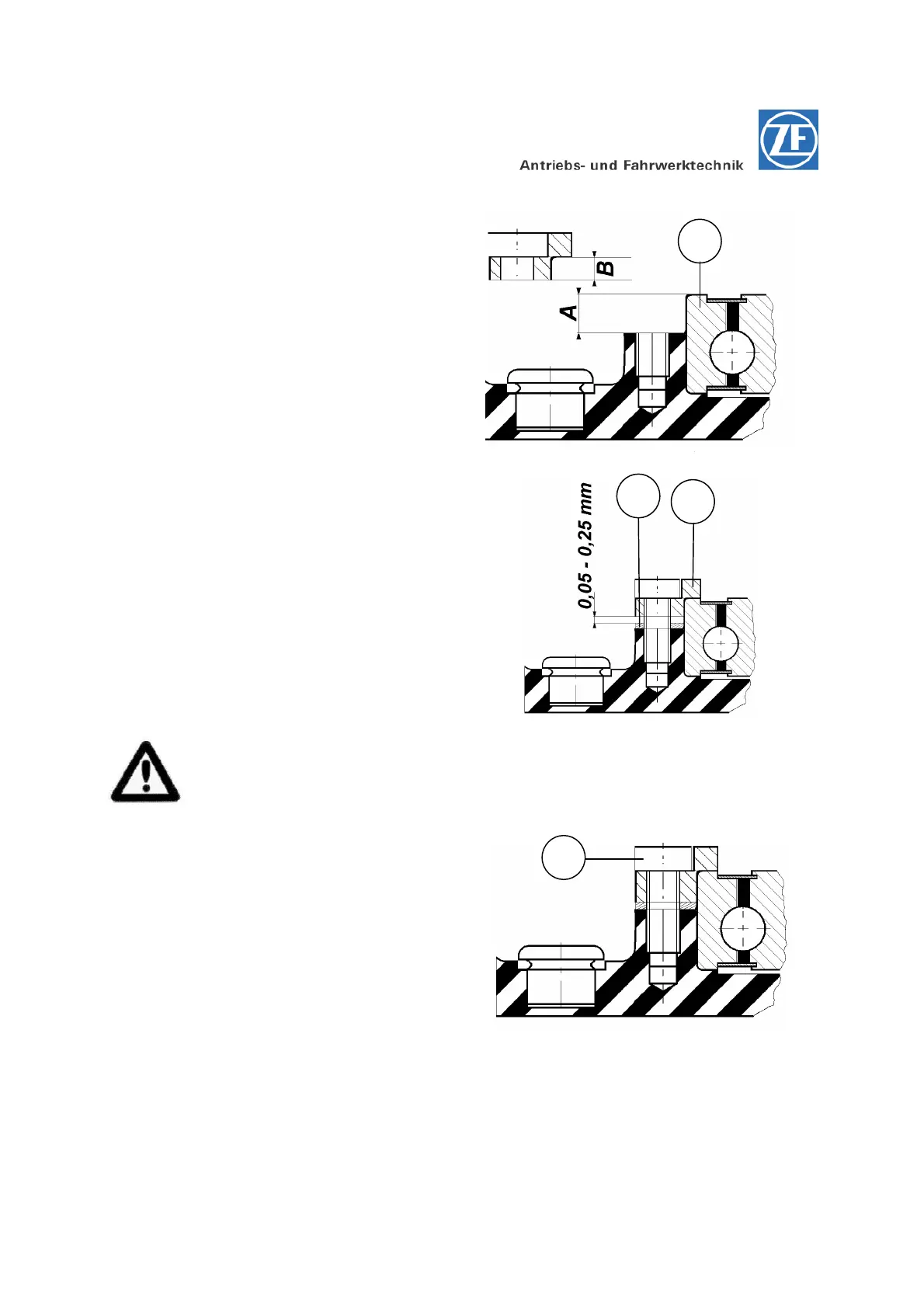

c) Calculate the thickness of the shim rings

(Item 02) to be inserted, so that the bearing

preload is reached.

d) Dim. A – Dim. B – 0.05 to 0.25 mm =

bearing preload

e) Prepare the required shim ring thickness

and insert it.

Figure 07

In order to obtain the bearing preload a gap of 0.05 – 0.25 mm must exist

before between the holding ring (Item 03) and the inserted shim rings (Item

02) before bolting. Bearing play and an excessive preload have a negative

effect on the service life of the pivoted bogie bearing.

After bolting

f) Put on one drop each of LOCTITE 242

onto the threads of the Allen screws M10

(Item 02) and fasten the holding ring (Item

03) with screws.

g) Tighten the screws crosswise.

h) Tightening torque: 46 Nm

Figure 08

02

03

01

02

Loading...

Loading...