起

重

机

说

明

Tr

ou

bleshooting

Maintenance Manual for Crawler Crane

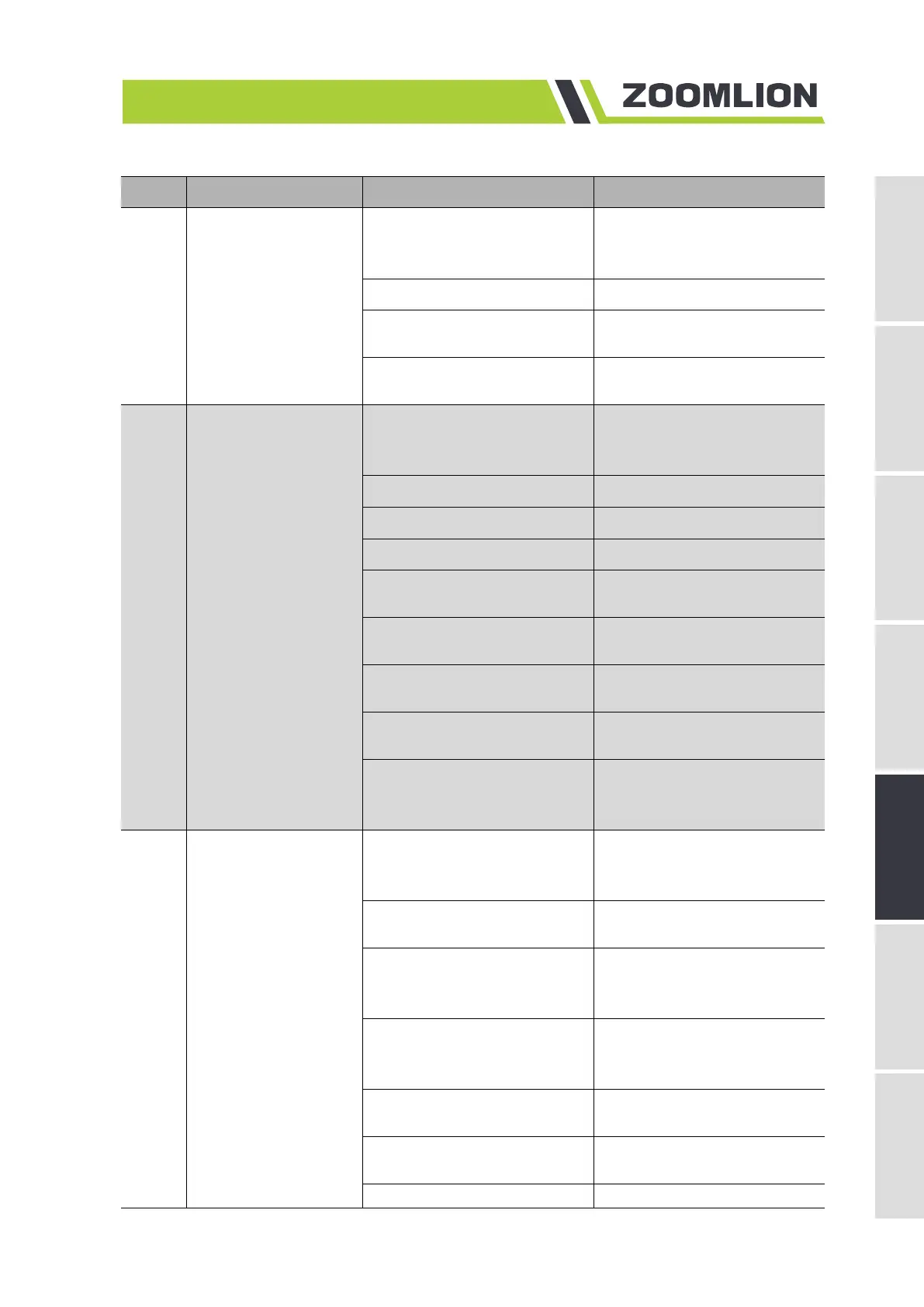

No. Troubles Causes Solutions

7

The speed of actuating

assembly is low.

1. The pump or motor leaks oil.

1. Check and repair the pump

or motor, or change them if

2. The oil pipeline is blocked. 2. Clean the oil pipeline.

3. The pilot pressure is not

3. Detect the pilot pressure. ※

4. The control lever is not

placed in proper position.

4. Adjust the position of control

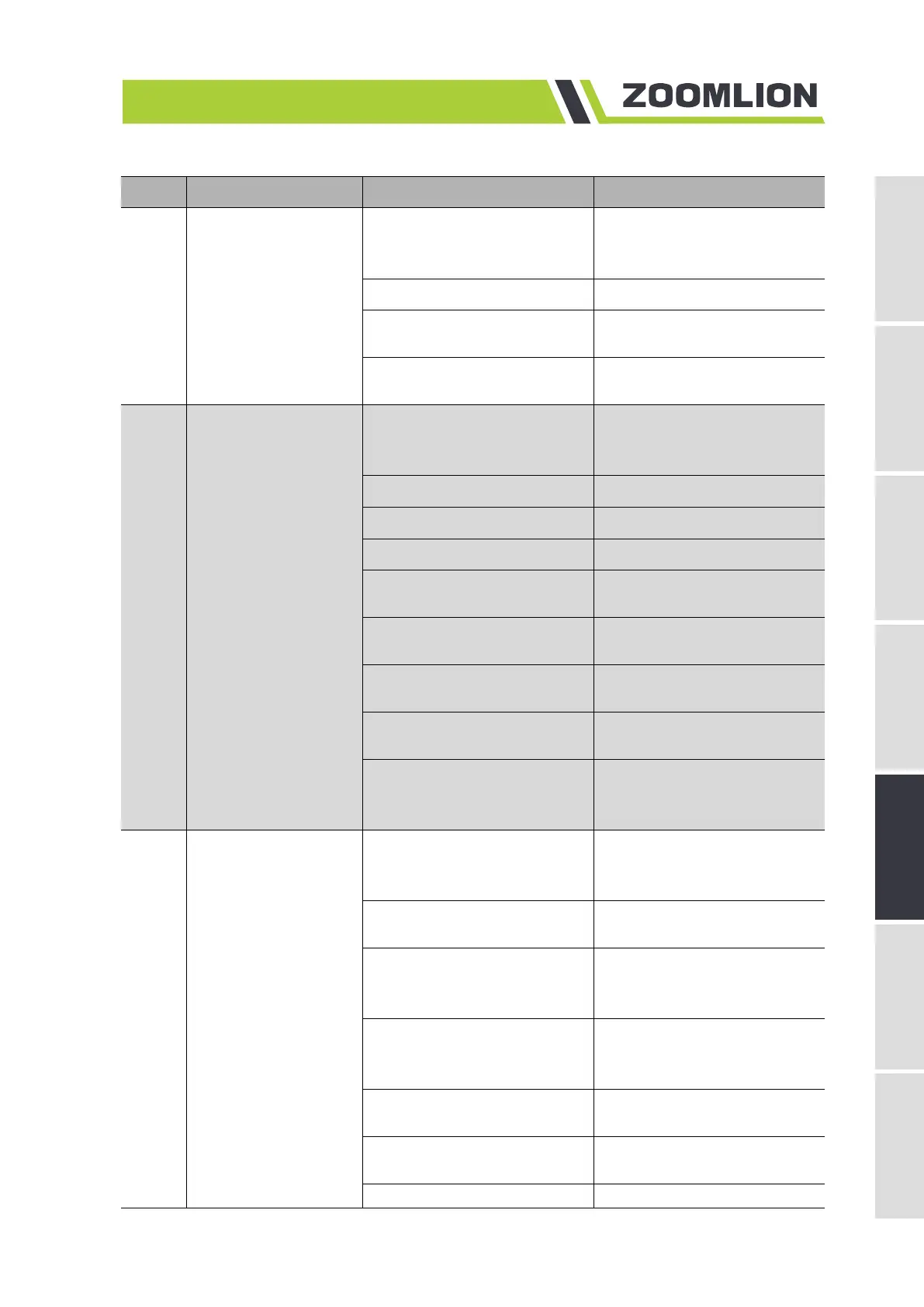

8

No movements are

performed by hoisting

winch 1 (or 2), or the

movements of hoisting

winch 1 (or 2) are

carried out weakly.

1. The hydraulic pump fails. 1. Check and repair the main

pump, or change it if

2. The oil pipeline is blocked. 2. Clean the oil pipeline.

3. The crane is overloaded. 3. Adjust the load.

4. The fuse of controller fails. 4. Change the fuse.

5. The hoisting winch 1 (or 2)

5. Change the control lever. ※

6. The circuit of main valve is

6. Change the circuit.

7. The brake cylinder is not

7. Detect the starting pressure

8. The quick-release coupling

8. Screw the quick-release

9. The pressure of overflow

valve on main valve is too low.

9. Detect the pressure of

overflow valve. Reset the

9

The brake of hoisting

winch 1 (or 2) is not

actuated.

1. The pilot pump fails. 1. Check and repair the pilot

pump, or change it if

2. The pressure relief valve of

2. Check and adjust the output

※

3. No signal is output from the

controller and brake solenoid

3. Check and repair brake

solenoid valve.

4. The oil line of brake leaks

oil.

4. Check and repair sealing

elements of oil line, or change

5. The pipeline of pilot system

5. Clean the pipeline.

6. The circuit of brake is out of

6. Change the circuit.

7. The fuse of controller fails.

5-9

Loading...

Loading...