T

roubleshooting

Maintenance Manual for Crawler Crane

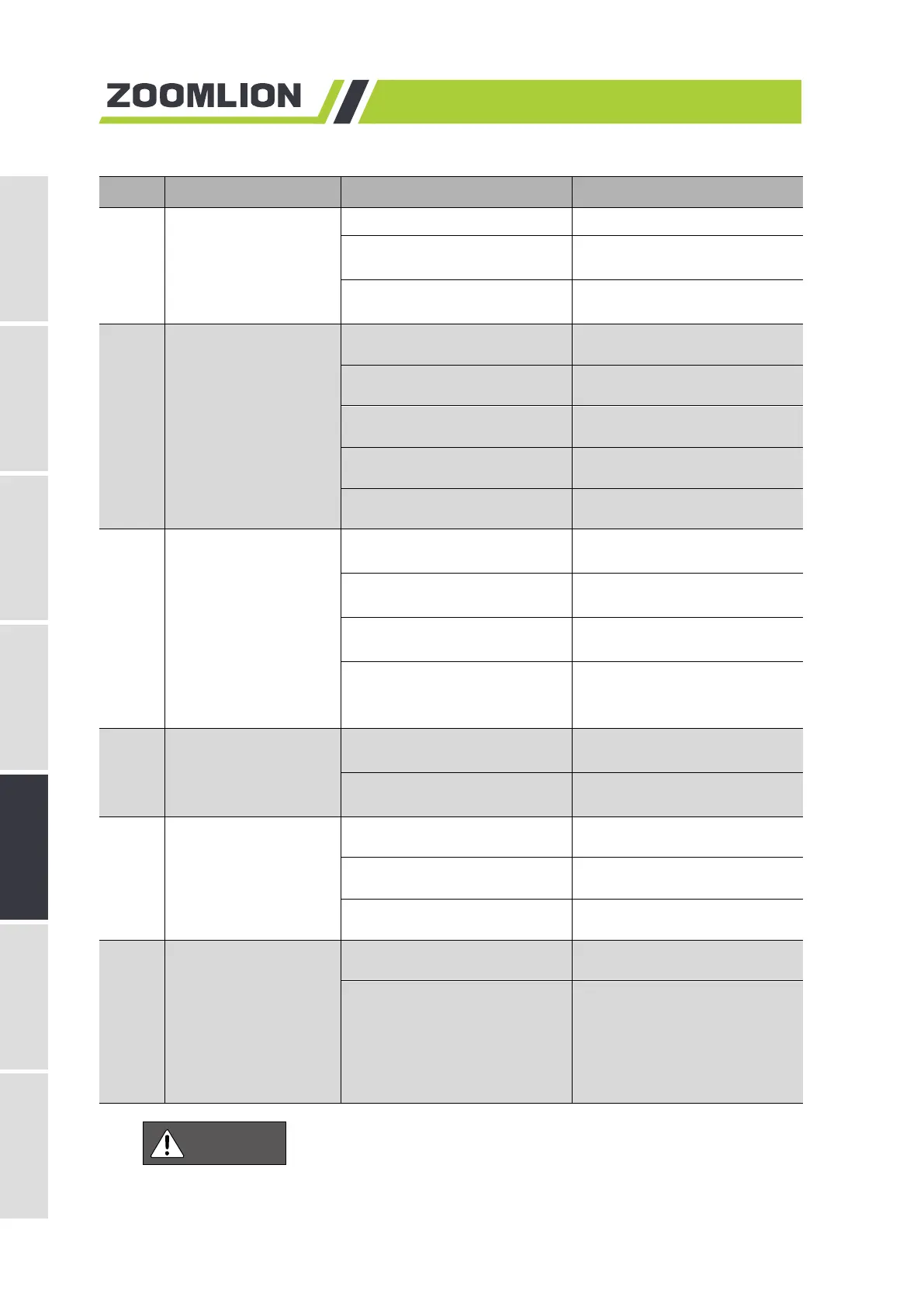

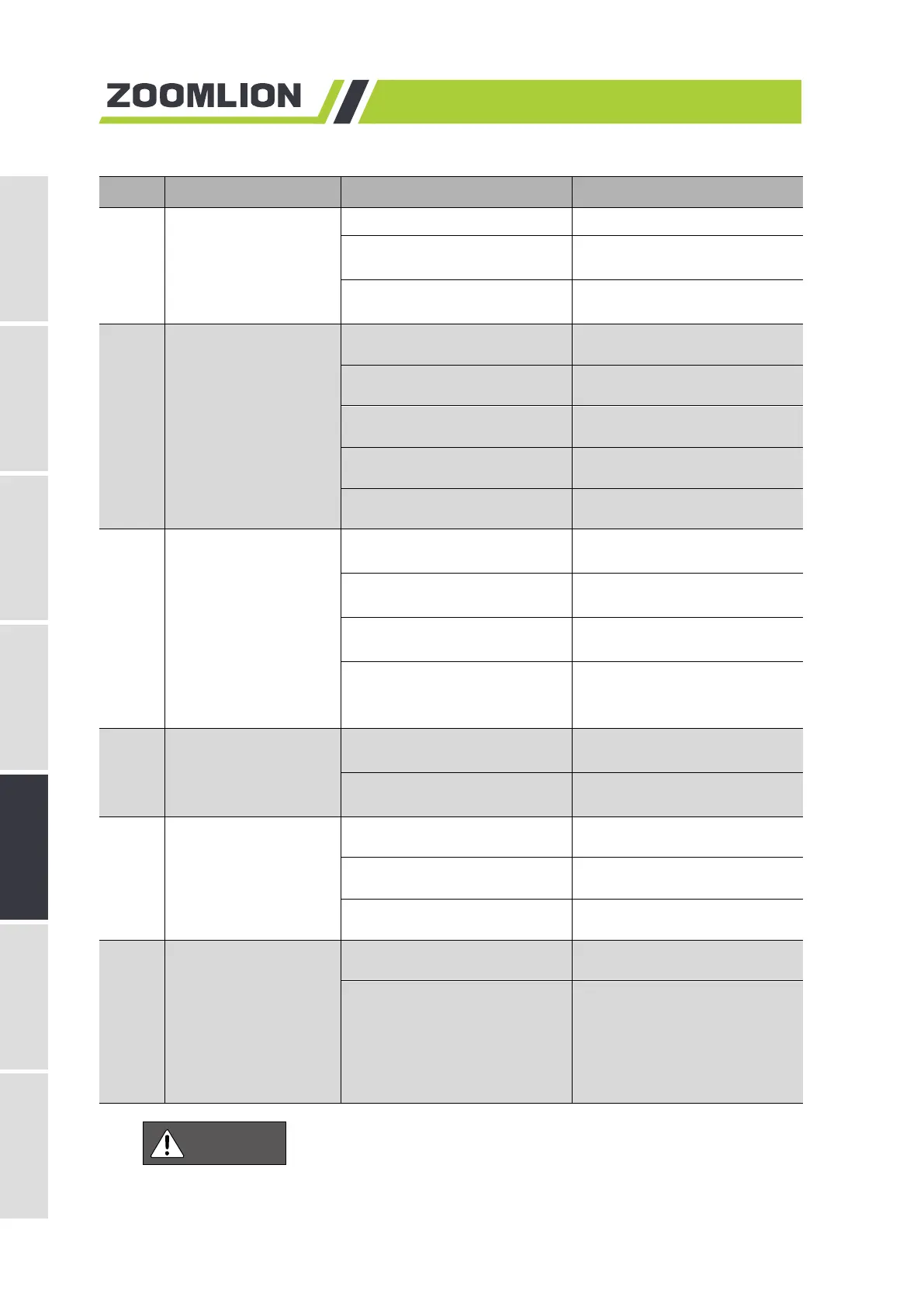

No. Troubles Causes Solutions

10

The hydraulic system

makes noise.

1. The oil viscosity is too low. 1. Change hydraulic oil.

2. The oil temperature is too

2. Preheat the hydraulic

3. The back pressure of oil

3. Modify the hydraulic

11

The oil temperature is

too high.

1. The radiator or oil pipeline is

1. Clean the radiator or oil

2. The brand of hydraulic oil is

wrong.

2. Change the hydraulic oil.

3. The hydraulic oil

3. Change the hydraulic oil.

4. The oil in the hydraulic oil

tank is insufficient.

4. Add oil to specific value.

5. The solenoid valve of cooler

5. Change the solenoid valve.

12

The hydraulic pipeline

vibrates fiercely.

1. There is an amount of air in

1. Discharge the air.

2. The pipe clamp is loose. 2. Adjust the pipe clamp and fix

3. The overflow valve or safety

3. Clean the valve. ※

4. The pump, motor or valve

fail.

4. Check and repair the pump,

motor or valve, or change them

13

The pipe fitting leaks

oil.

1. The pipe fitting is not

1. Tighten the fitting.

2. The sealing element is

2. Change the sealing element.

14 The hose bursts.

1. The hose does not match

the applied pressure.

2. The hose is aging and

2. Change the hose.

3. The fitting of hose is

blocked.

3. Clean the hose and fitting.

15

The connectors of

hydraulic pump and

hydraulic motor leak

oil.

1. The reducer leaks gear oil.

1. Change the oil seal of

2. The hydraulic pump and

hydraulic motor leak oil.

2. Detect the pressure of oil

drain hole of pump and motor.

If it exceeds 3bar, modify the

oil drainage pipeline, and

change the oil seal of pump

※

If the component marked with ※ fails, never dismember or adjust it. You must contact

the crane manufacturer.

5-10

Loading...

Loading...