©2018, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection.

48

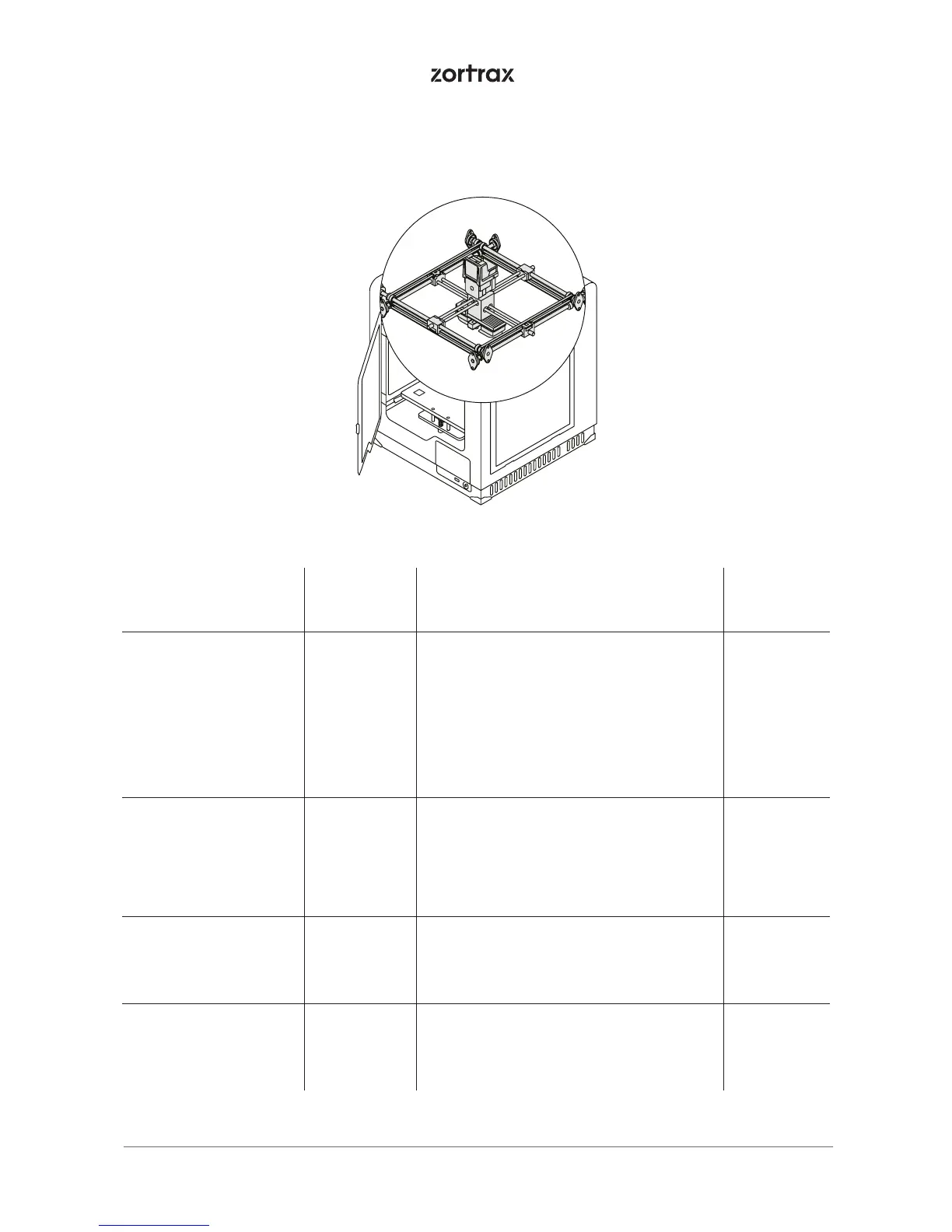

4. X/Y axes; extruder guide rails

Activity Frequency Solutions to the problems

Necessary

accessories

Checking if the axes

and the extruder

guide rails are clean

from material remains

and dust

Before each

printing

It is possible to feel slight resistance while

checking if the extruder moves freely on

the guide rails. In such case you should

check if the X/Y axes and the extruder

guide rails are covered with black grime.

The axes and guide rails should be

cleaned with a cloth damped in acetone

and then lubricated with grease supplied

in the Starter Kit

-

Checking the tension of

the drive belts on the

X/Y axes

Every 300

working

hours

In order to check the tension of the drive

belts on the X/Y axes, move the extruder

to the central point and gently tug the

belts. If the belts are loosened, tighten the

screws placed on the top part of the X/Y

axes blocks

-

Checking the tension of

the drive belts between

the motors and the

X/Y axes

Every 300

working

hours

- -

Checking if the screws

on the X/Y axes and

the motors pulleys are

tightened

Every 300

working

hours

- -

Loading...

Loading...