18

POWER DIRECT VENTING (PDV)

The combustion air intake and exhaust vent system and termination

may be installed in one of the following type terminations:

1. Horizontal (2 Pipe) (air intake and exhaust vent).

2. Vertical (2 Pipe) (air intake and exhaust vent)

3. Concentric (horizontal/side wall installation).

4. Concentric (vertical/roof installation).

5. Low Prole (2 Pipe) (air intake and exhaust vent). Horizontal

use only.

CONNECT FIELD

SUPPLIED FLEXIBLE

DRAIN HOSE TO BARB

FITTING AND FORM A

LOOP WATER TRAP IN

DRAIN HOSE

RUN DRAIN HOSE

TO SUITABLE FLOOR

DRAIN SEPARATELY

FROM OTHER

CONDENSATE DRAINS

FIELD SUPPLIED

2” x 2” x 1/2” TEE

WITH HOSE BARB

FITTING INSTALLED

FACTORY-SUPPLIED

INTAKE AIR

CONNECTION

INSTALL TEE FITTING AS CLOSE

TO WATER HEATER

INTAKE AIR CONNECTION AS

POSSIBLE

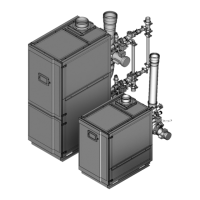

Figure 14. Intake Air Condensate Tee Installation

DIRECT VENT AIR INTAKE MOISTURE PROTECTION

The air intake piping in a direct vent system will normally not have

any moisture accumulation in it. However, in certain cases, moisture

may build up and needs to be drained. Typical situations include,

but are not limited to:

• Cold outdoor temperature, particularly if the air inlet is short

• Heater being used mostly for space heating

• Air inlet pipe has vertical rise near the heater

Installations with any of these conditions are required to provide a

moisture drain with a trap that ows to a waste drain. See

Figure 14.

A horizontal section of the air inlet pipe, near the heater should

include a 2” x 2” x 1/2” tee and a hose barb tting to drain the water.

The tee should be as close to the heater as is practical. The drain

tubing in any installation should have a loop trap and ow to an

appropriate waste drain. The air intake drain line must be entirely

separate from the exhaust vent outlet condensate line.

Loading...

Loading...