TroubleshootingGuide

31|Page

CHECKINGTHEFLOWSENSOR

Ifthetanklessunitisproperlyconnectedtowater,gas,andpowersuppliesbutthefanmotordoesnot

initiatewhenwaterisrunthroughit,theflowsensorismostlikelynotworkingproperlyandnottelling

thePCBoardtoinitiate.

1) TOOLS

‐Gatherthefollowingmaterialstogether:

a. Degreaserinapumpactionbottle

b. #2PhilipsScrewDriver

c. Flashlight

d. OldTowels,atleastthree

2) PREPARETHEUNIT

–

a. Draintheunitbyfollowingtheproceduresonp.21.

b. Disconnectpowertotheunit.

3) FRONTCOVER

‐Removethefrontcover.

4) COMPUTERBOARD

a. Removethescrewholdingthecomputerboardtothe

manifold,andletthecomputerboardhanginfrontoftheunit

b. Disconnecttheflowsensorwire.

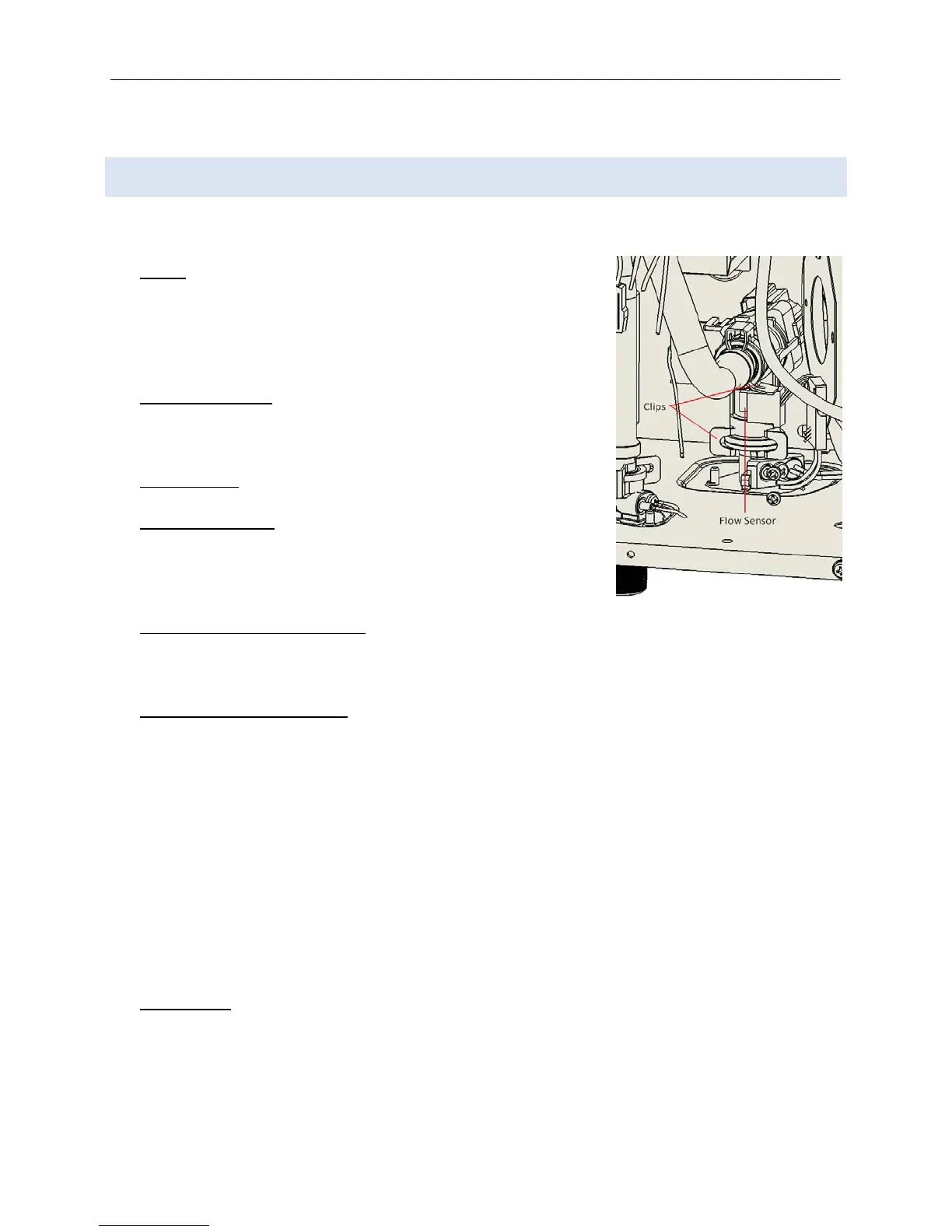

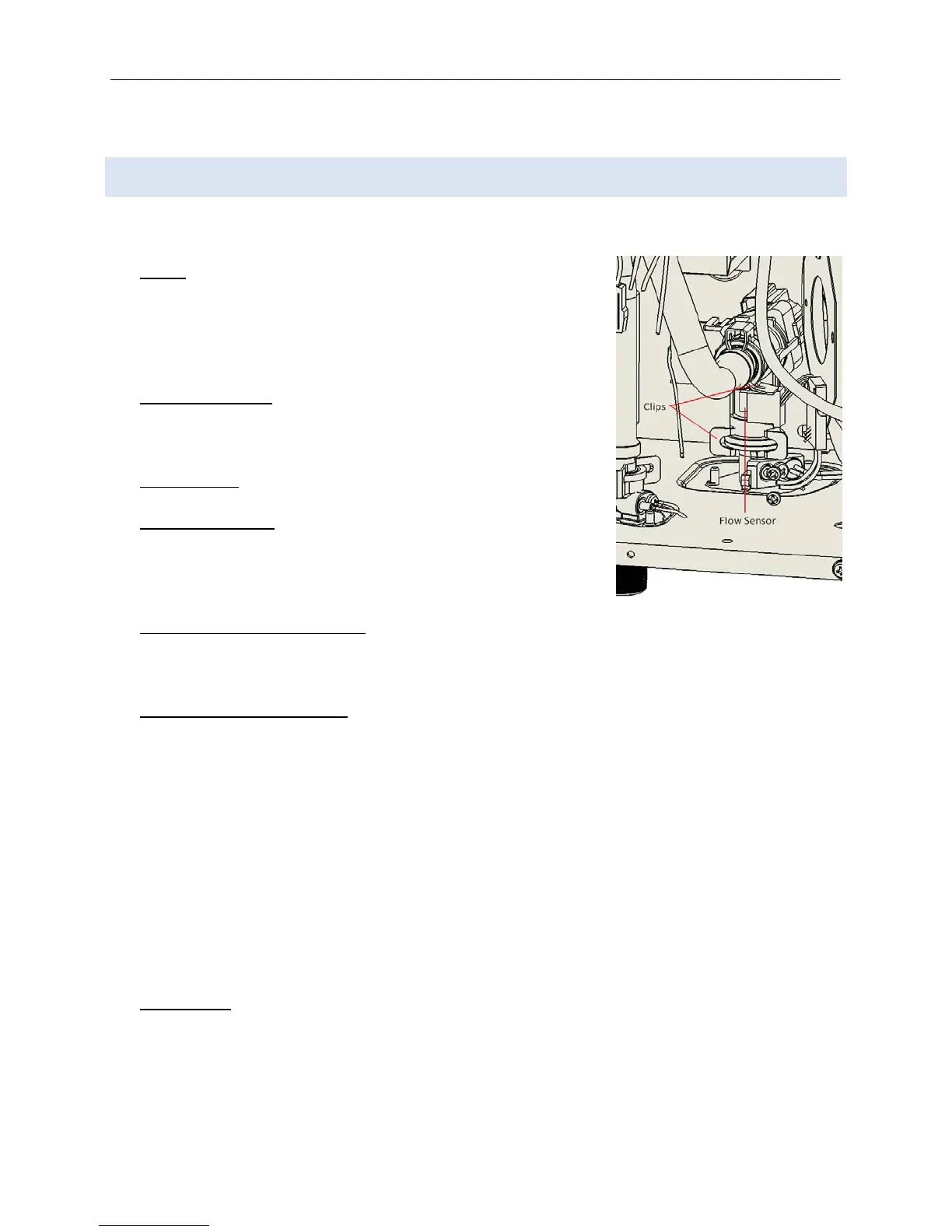

5) DISCONNECTFROMWATERWAY

a. Theflowsensorislocatedbehindthecomputerboard.

b. Removethewaterwayclipsoneachsideoftheflowsensorbypushingonthetabs.

6) CHECKINGTHEFLOWSENSOR

a. Checkforfunctionality .Flow rateisdeterminedbyanimpellerthatspinsasfluidrunsthrough

it.

b. Blowintotheinletoftheflowsensor.Listenforthespinningimpeller;itshouldspinfreelyfora

fewseconds.Ifitcomestorestabruptlyordoesn’tspinatall,itneedstobecleanedor

replaced.

c. Placetheflowsensorintoacon taineroflemonjuiceoranotherdegreaserfor30minutesand

checkthespinningcapabilityagain.

d. Testthecleanedflowsensorby“jumping”thesystem:

i. Reattachtheflowsensorwires.

ii. Turnpowerbackontotheunit.(GASSHOULDSTILLBEOFF)

iii. Blowintotheflowsensor;ifthefaninitiates,theflowsensorsuccessfullyreadthe

airflowandshouldnowworkproperly.

7) REASSEMBLE‐Reassembletheunitinreverseorder.EnsurethattheO‐ringsandwaterwayclipsare

allinplace.

Figure34

Loading...

Loading...