Subtract the measured liquid line

temperature from the saturated temperature

to determine the liquid sub-cooling.

Compare calculated sub-cooling to Table 3

below for the appropriate unit type and

options.

Checking Evaporator Superheat

Measure the temperature of the suction line

close to the compressor.

Read gauge pressure at the suction line close

to the compressor.

Convert the pressure obtained to a saturated

temperature using the appropriate refrigerant

temperature-pressure chart.

Subtract the saturated temperature from the

measured suction line temperature to

determine the evaporator superheat.

Compare calculated superheat to Table 3

below for the appropriate unit type and

options.

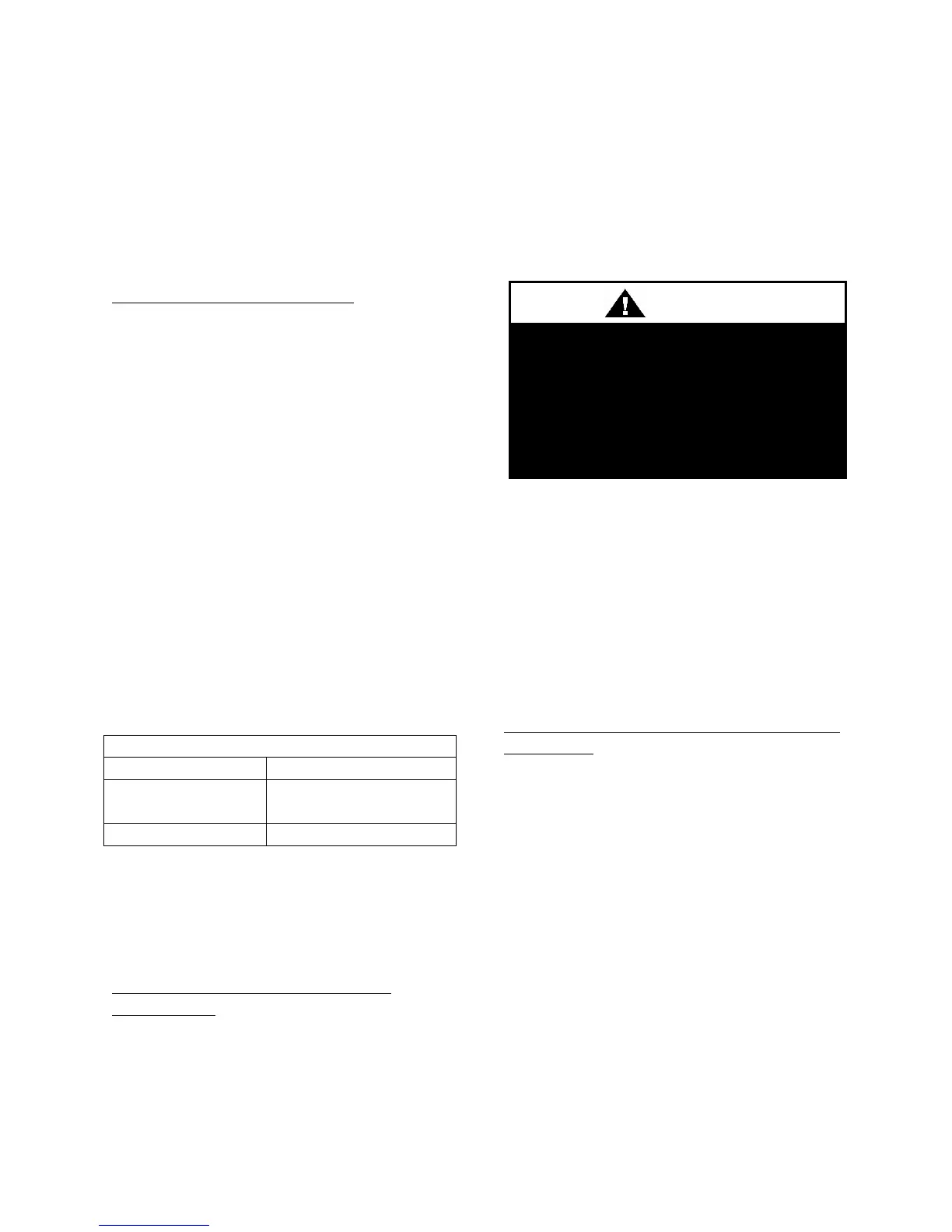

Table 3 - Acceptable Refrigeration Circuit

Values

Air-Cooled Cond./Air-Source Heat Pump

Sub-Cooling with

Hot Gas Reheat**

*In cooling mode operation

**Sub-cooling must be increased by 2°F per

20 feet of vertical liquid line rise for R-410A

***Superheat will increase with long

suction line runs.

Adjusting Sub-cooling and Superheat

Temperatures

The system is overcharged if the sub-cooling

temperature is too high and the evaporator is

fully loaded (low loads on the evaporator

result in increased sub-cooling) and the

evaporator superheat is within the

temperature range as shown in Table 3 (high

superheat results in increased sub-cooling)

Correct an overcharged system by reducing

the amount of refrigerant in the system to

lower the sub-cooling.

The system is undercharged if the superheat

is too high and the sub-cooling is too low

Correct an undercharged system by adding

refrigerant to the system to reduce superheat

and raise sub-cooling.

If the sub-cooling is correct and the

superheat is too high, the TXV may need

adjustment to correct the superheat.

Special Low Ambient Option Charging

Instructions

For units equipped with low ambient control

(LAC) refrigerant flood back option being

charged when the ambient temperature is

warm:

Once enough charge has been added to get

the evaporator superheat and sub-cooling

values to the correct setting, more charge

must be added. Add approximately 80% of

the receiver tank volume to the charge to

help fill the receiver tank. The additional

charge is required for the system when

running in cold ambient conditions.

DO NOT OVERCHARGE!

Refrigerant overcharging leads to

excess refrigerant in the condenser

coils resulting in elevated compressor

discharge pressure.

Loading...

Loading...