Electrical

Verify the unit nameplate agrees with the

power supply. Connect power and control

field wiring as shown on the unit wiring

diagram provided with the unit.

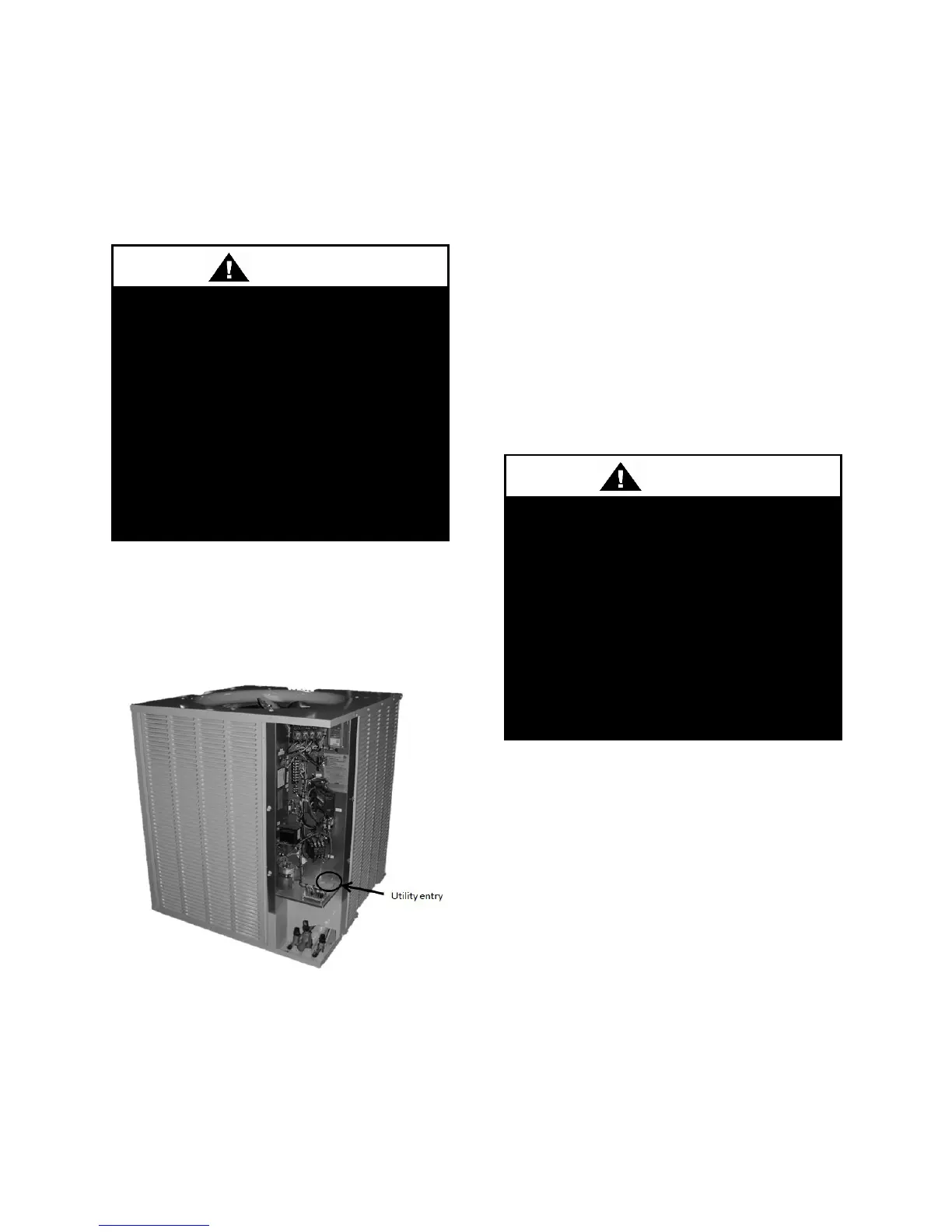

Route power and control wiring, separately,

through the utility entry right above the

service valves. Do not run power and signal

wires in the same conduit.

Figure 3 – Utility Entry

Size supply conductors based on the unit

MCA rating. Supply conductors must be

rated a minimum of 75°C.

Protect the branch circuit in accordance with

code requirements. The unit must be

electrically grounded in accordance with

local codes, or in the absence of local codes,

the current National Electric Code,

ANSI/NFPA 70 or the current Canadian

Electrical Code CSA C22.1.

Note: Units are factory wired for 208V,

230V, 460V or 575V. In some units, the

208V and 230V options may also be

provided in single or three phase

configurations. The transformer

configuration must be checked by a

qualified technician prior to startup.

Wire power leads to the unit terminal block.

All wiring beyond this point has been done

by the manufacturer and cannot be modified

without affecting the unit's agency/safety

certification.

All units require field supplied electrical

overcurrent and short circuit protection.

Device must not be sized larger than the

Maximum Overcurrent Protection (MOP)

shown on the unit nameplate.

Codes may require a disconnect switch be

within sight of the unit.

3-PHASE ROTATION

Rotation must be checked on all

MOTORS AND COMPRESSORS of

three phase units. Condenser fan

motors should be checked by a

qualified service technician at startup

and any wiring alteration should only

be made at the unit power

connection.

ELECTRIC SHOCK

Electric shock hazard. Before

attempting to perform any installation,

service, or maintenance, shut off all

electrical power to the unit at the

disconnect switches. Unit may have

multiple power supplies. Failure to

disconnect power could result in

dangerous operation, serious injury,

death or property damage.

Loading...

Loading...