11266HSH MODBUS TRANSMITTER | PRESSURE/TEMPERATURE MULTIVARIABLE | OI/266HSHMT-EN REV. A

6 Setup

6.1 Temperature measurement

— Mount the temperature sensor in the downstream pipe

of the primary element.

— Consider the downstream straight pipe requirements.

— If there is a significant difference between the

temperature of the measuring medium and the

ambient temperature, the measuring error caused by

heat conduction must be minimized by insulating the

installation location accordingly.

— Use class “A” sensors to maximize accuracy.

6.2 General information

The relevant directives must be complied with for the

electrical installation! Because the transmitter cannot be

switched off, surge protection devices, lightning

protection, or grid disconnect possibilities must be

provided at the plant.

Check that the existing supply voltage corresponds to that

indicated on the rating plate. The same lines are used for

both the power supply and the output signal.

If an optional surge protector is provided and if the

transmitter is used in a hazardous area, energy must only

be supplied via a voltage source with electrical isolation

from the grid. Because the inherently safe power circuits of

the transmitter are grounded, a sufficient equipotential

bonding must be ensured for the entire supply line.

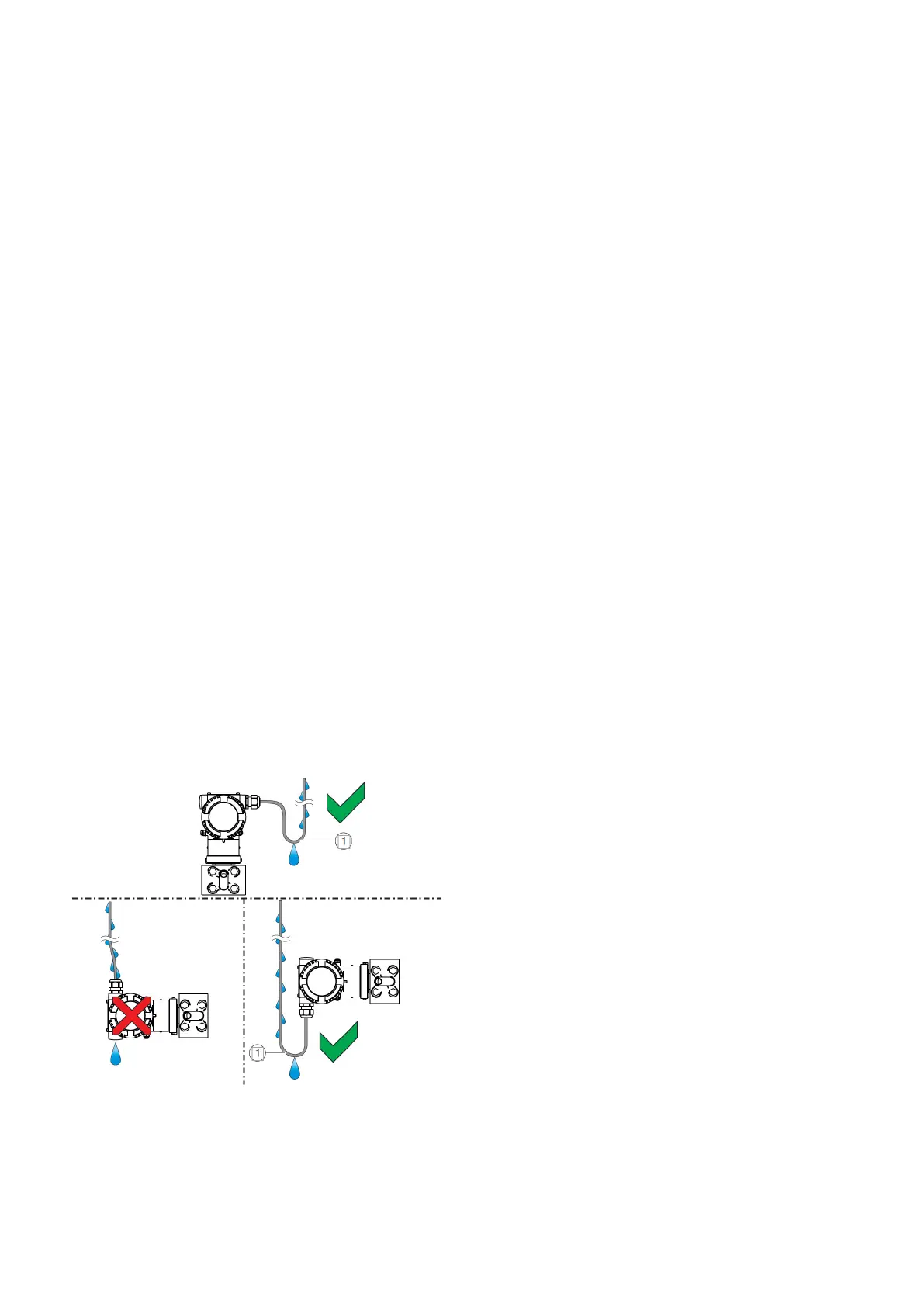

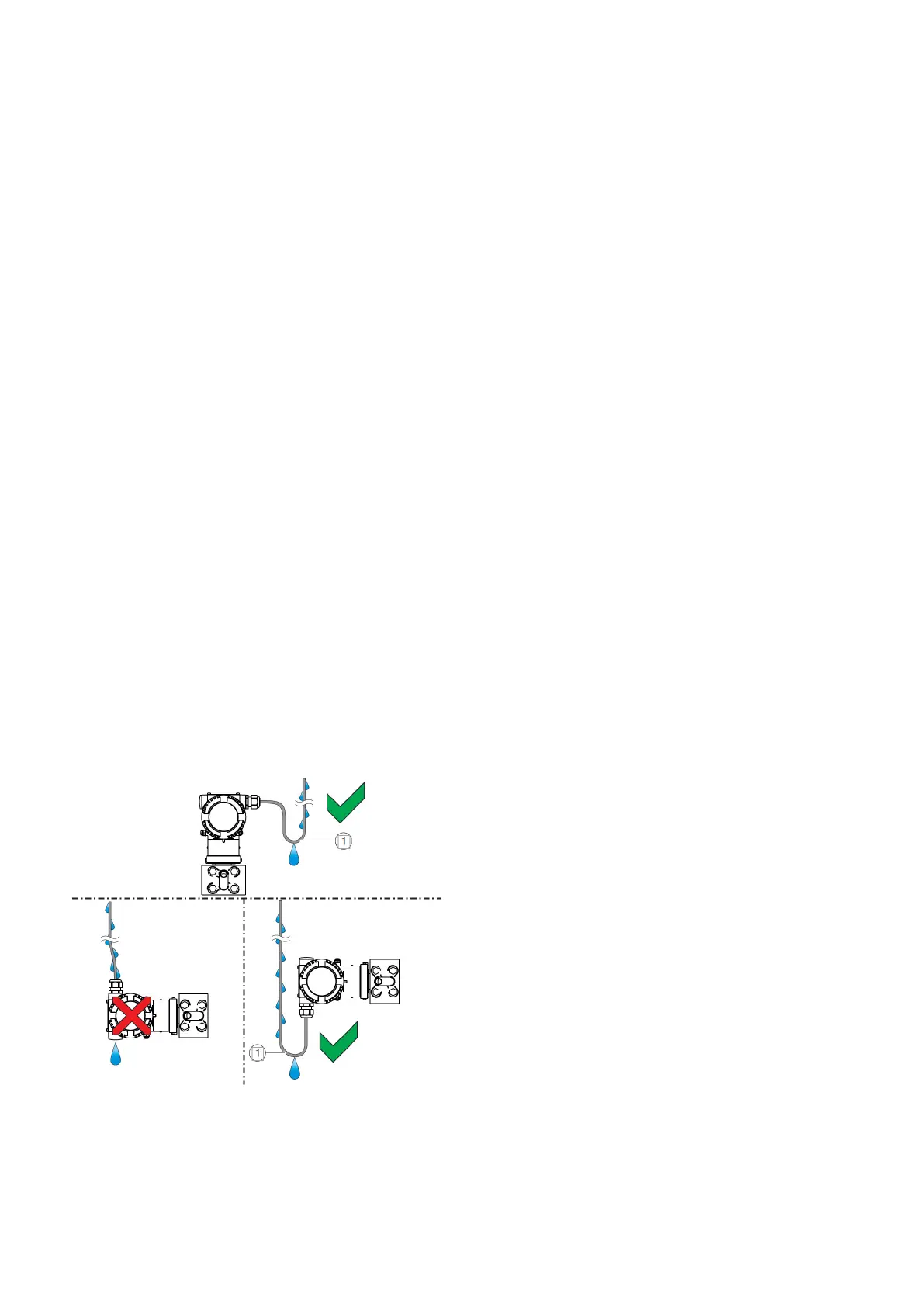

8.6.3 Installing the connecting cables

Ensure that a drip loop (water trap) is used when installing

the connecting cables for the sensor.

If necessary, rotate the transmitter housing accordingly..

NOTICE

If cable glands are not used, the red transport screw

plugs must be replaced with suitable screw plugs when

the transmitter is installed. This is because the transport

screw plugs are not certified as protected against

explosion. This requirement is particularly relevant in

hazardous areas

Cable entries with an M20 x 1.5 thread

Devices with an M20 x 1.5 thread are optional supplied

with factory-installed cable glands and sealing plugs.

Cable entries with a 1/2” NPT thread

The supplied transport sealing plugs do not have IP

rating 4X / IP67 and are not approved for use in

potentially explosive atmospheres.

The transport sealing plugs must be replaced with

suitable cable glands or sealing plugs during device

installation. When selecting the cable glands or sealing

plugs, make sure they have the required IP rating and

explosion protection!

To offer IP rating 4X / IP67, the cable glands / sealing

plugs must be screwed in using a suitable sealing

compound.

Cable entry for PT100 temperature sensor

A metal cable gland should always be used for the Pt100

cable since a shielded cable is used.

Connect the shielding within the metal cable gland!

To offer IP rating 4X / IP67, the cable glands / sealing

plugs must be screwed in using a suitable sealing

compound.

Safety instructions for use in Division 1

Conduit requirements for Div. 1 installations are not

addressed in this procedure. To avoid creating a

hazardous situation, ensure compliance with the

applicable standards, regulations, and recommendations

for installation in the country of use. Resistance

thermometer installation in classified Div. 1

Fig. 9: Installing the connecting cables

1. Drip loop

6.4 Supply requirement

For signal/power connection use twisted, stranded pairs

of wiring no 18 to 22 AWG / 0.8 to 0.35mm2 ø up to 5,000

feet (1500 meters). Longer loops require larger wire.

If a shielded wire is used, the shield should be grounded

only at one end, not both ends. In case of wiring at

transmitter end, use the terminal located inside the

housing marked with the appropriate sign.

For Ex ia and other intrinsically safe approval power supply

must not exceed 30 V DC.

Minimum operating voltage increase to 12.3 V DC with

optional surge protector or to 10.8 V DC with optional

conformity to NAMUR NE 21 (2004).

For maximum power supply voltage please refer to the top

identification plate of the transmitter.

The actual possible line length of the electrical circuit

depends on the total capacitance and resistance, and can

be estimated using the following formula:

6.3 Cable entries

The electrical connection is made via cable entries with a

1/2” NPT or M20 x 1.5 thread.

Loading...

Loading...