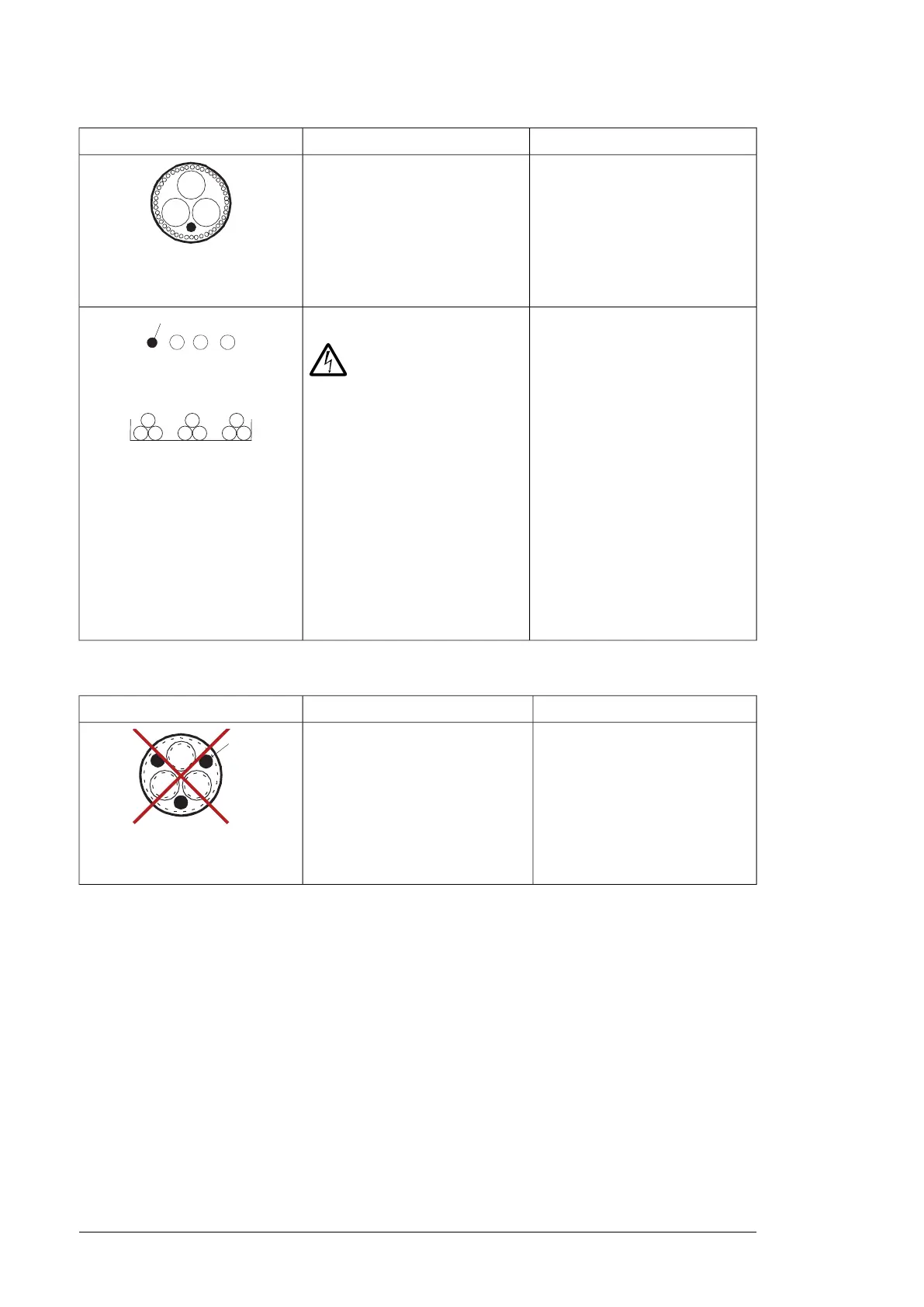

Use as motor cablingUse as input power cablingCable type

Yes with motors up to 100 kW

(135 hp). A potential equalization

between the frames of motor and

driven equipment is required.

Yes

Well-shielded (Al/Cu shield or ar-

mor) four-conductor cable (three

phase conductors and a PE)

NoYes

WARNING!

If you use unshielded high-

power input power cables

in an IT network, make sure

that the non-conductive

outer sheath (jacket) of the

cables have good contact

with a properly grounded

conductive surface, for ex-

ample, install the cables on

a properly grounded cable

tray. Otherwise voltage may

become present on the non-

conductive outer sheath of

the cables, and there is

even a risk of an electric

shock.

A single-core cable system: three

phase conductors and PE conductor

on cable tray

Preferable cable arrangement to

avoid voltage or current unbalance

between the phases

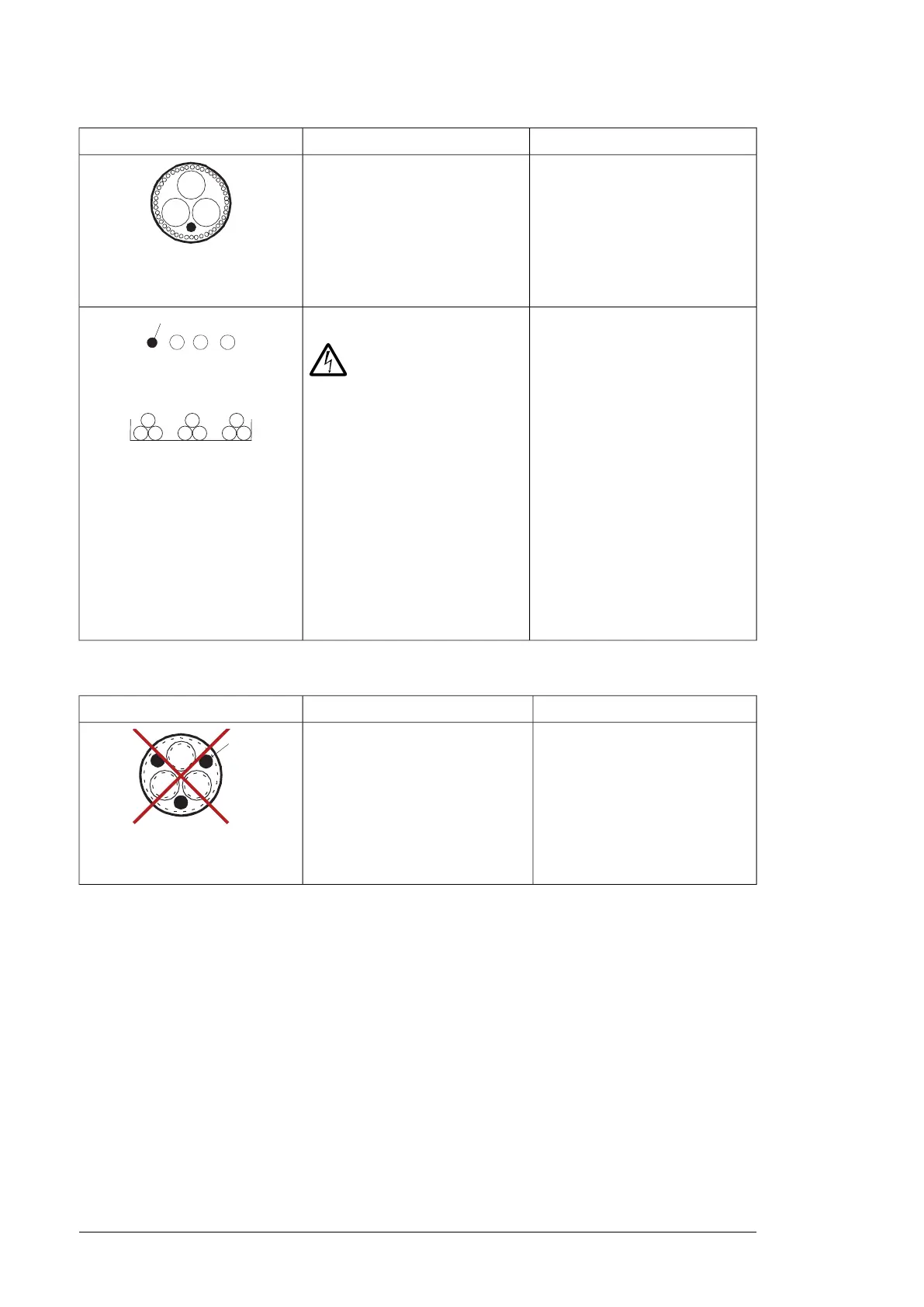

Not allowed power cable types

Use as motor cablingUse as input power cablingCable type

NoNo

Symmetrical shielded cable with in-

dividual shields for each phase

conductor

■ Power cable shield

If the cable shield is used as the sole PE conductor, make sure that its conductivity agrees

with the PE conductor requirements.

To effectively suppress radiated and conducted radio-frequency emissions, the cable shield

conductivity must be at least 1/10 of the phase conductor conductivity. The requirements

are easily met with a copper or aluminum shield. The minimum requirement of the motor

cable shield of the drive is shown below. It consists of a concentric layer of copper wires

with an open helix of copper tape or copper wire. The better and tighter the shield, the lower

the emission level and bearing currents.

26 Electrical planning guidelines

Loading...

Loading...