Routing the cables

■ Guidelines for routing the cables

• Route the motor cable away from other cables.

• Avoid long parallel runs of power cables with other cables. See the allowed minimum

distances below. You can install motor cables of several drives in parallel.

• Install the motor cable, input power cable and control cables on separate trays.

• Make sure that the cable trays have good electrical bonding to each other and to the

grounding electrodes. You can use aluminum tray systems to improve local equalizing

of potential.

• Where control cables must cross power cables, make sure they are arranged at an

angle as near to 90 degrees as possible.

• Do not run extra cables through the drive.

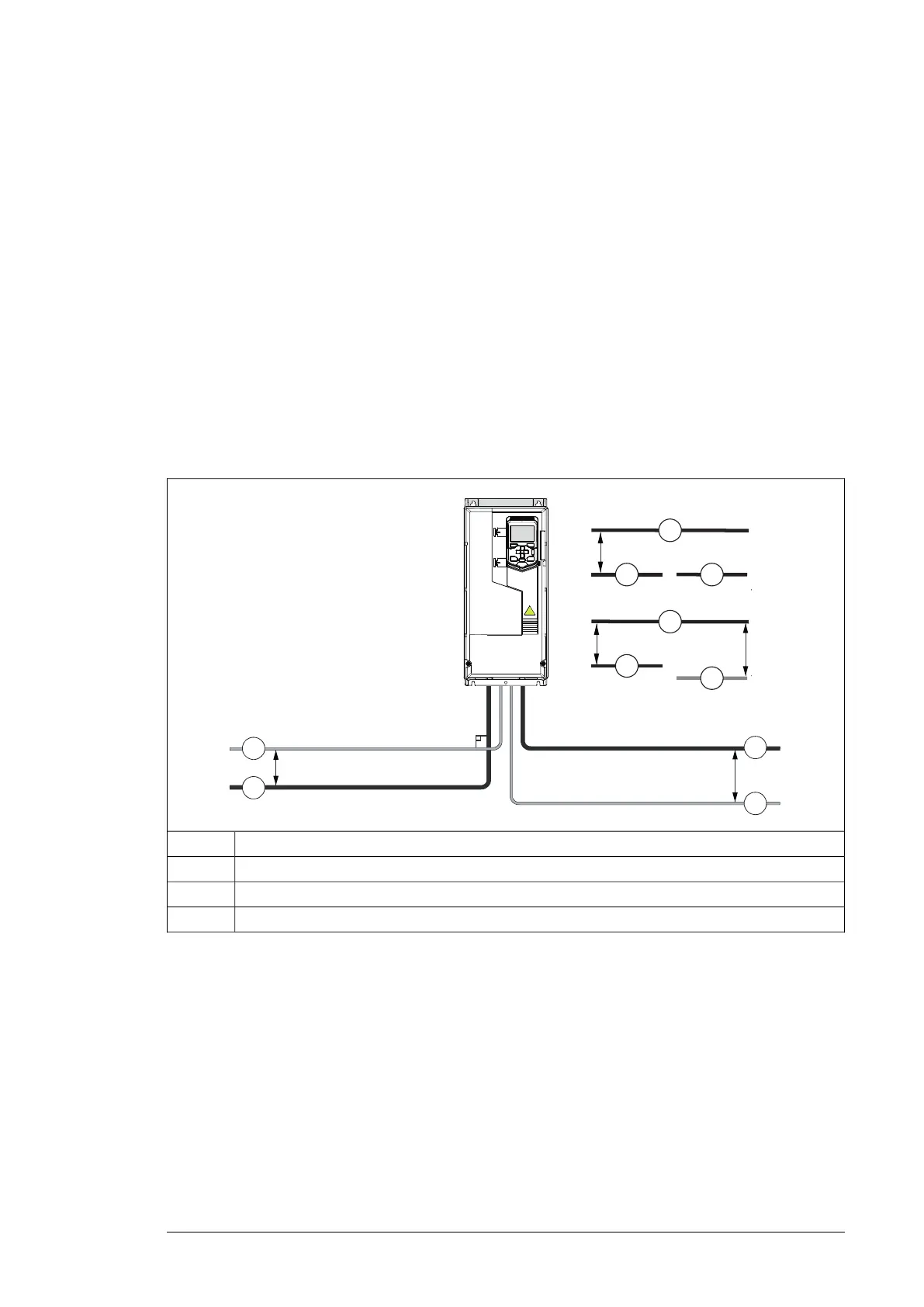

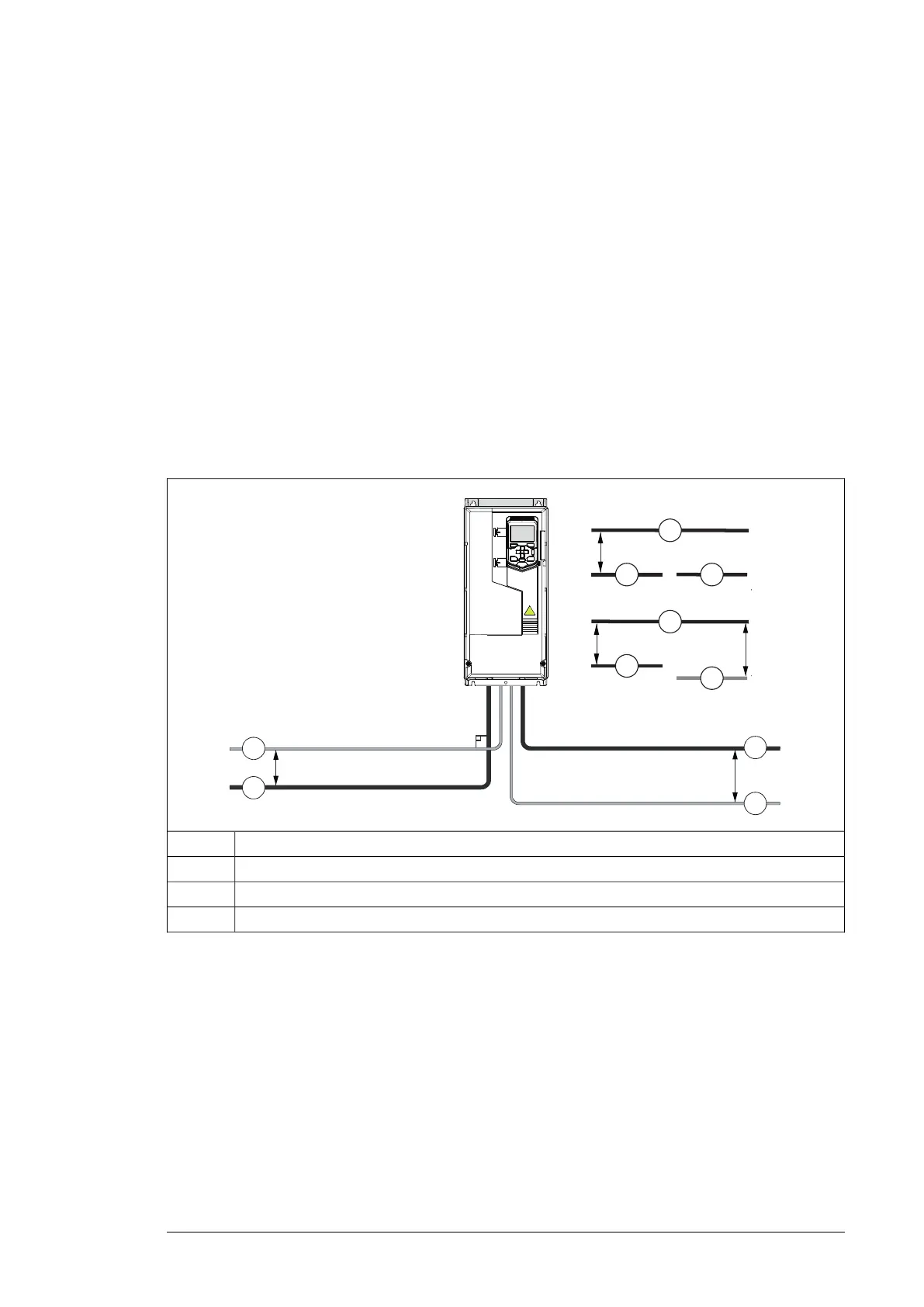

This figure illustrates the cable routing guidelines with an example drive.

min. 200 mm (8 in)

90°

*min. 500 mm (20 in)

1

2

3

3

2

1

4

min. 300 mm (12 in)

2

4

3

min. 300 mm (12 in)

*

Motor cable1

Input power cable2

Control cable3

Brake resistor or chopper cable (if any)4

Electrical planning guidelines 29

Loading...

Loading...