ControlMaster CM30 | Universal process controller,

1

/

4

DIN | DS/CM30–EN Rev. L 3

Highly scalable

The CM30 is highly scalable in terms of both hardware and software, to fulfill the demands of the simplest to the most complex

process. The basic CM30 meets the needs of a simple control loop. Templates and control functionality can be increased by

adding function keys to the basic model. Each function key added provides additional templates and functionality as shown in

Fig. 1, while retaining previous templates and functionality. For I/O builds, see also Ordering information on page 23.

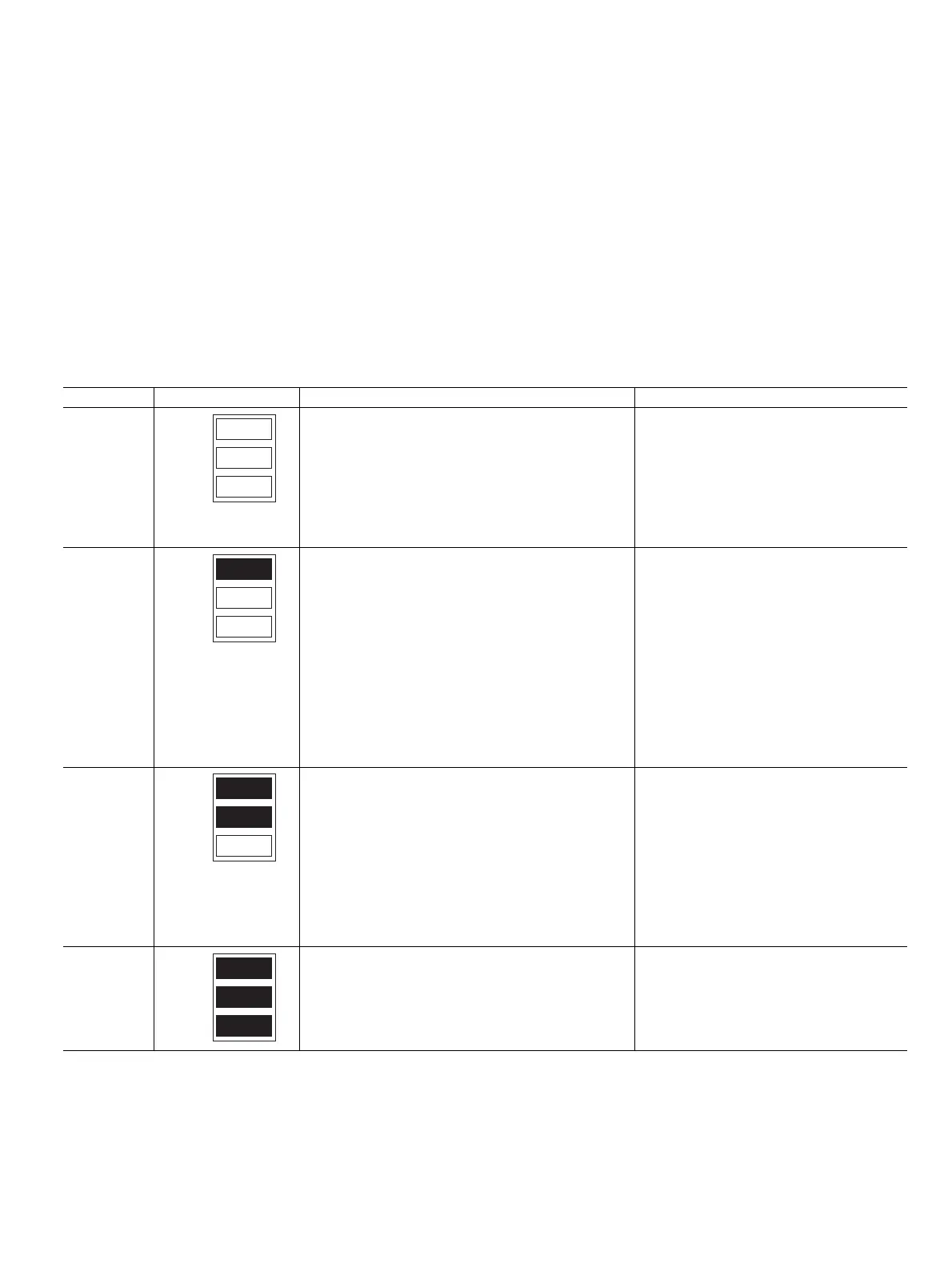

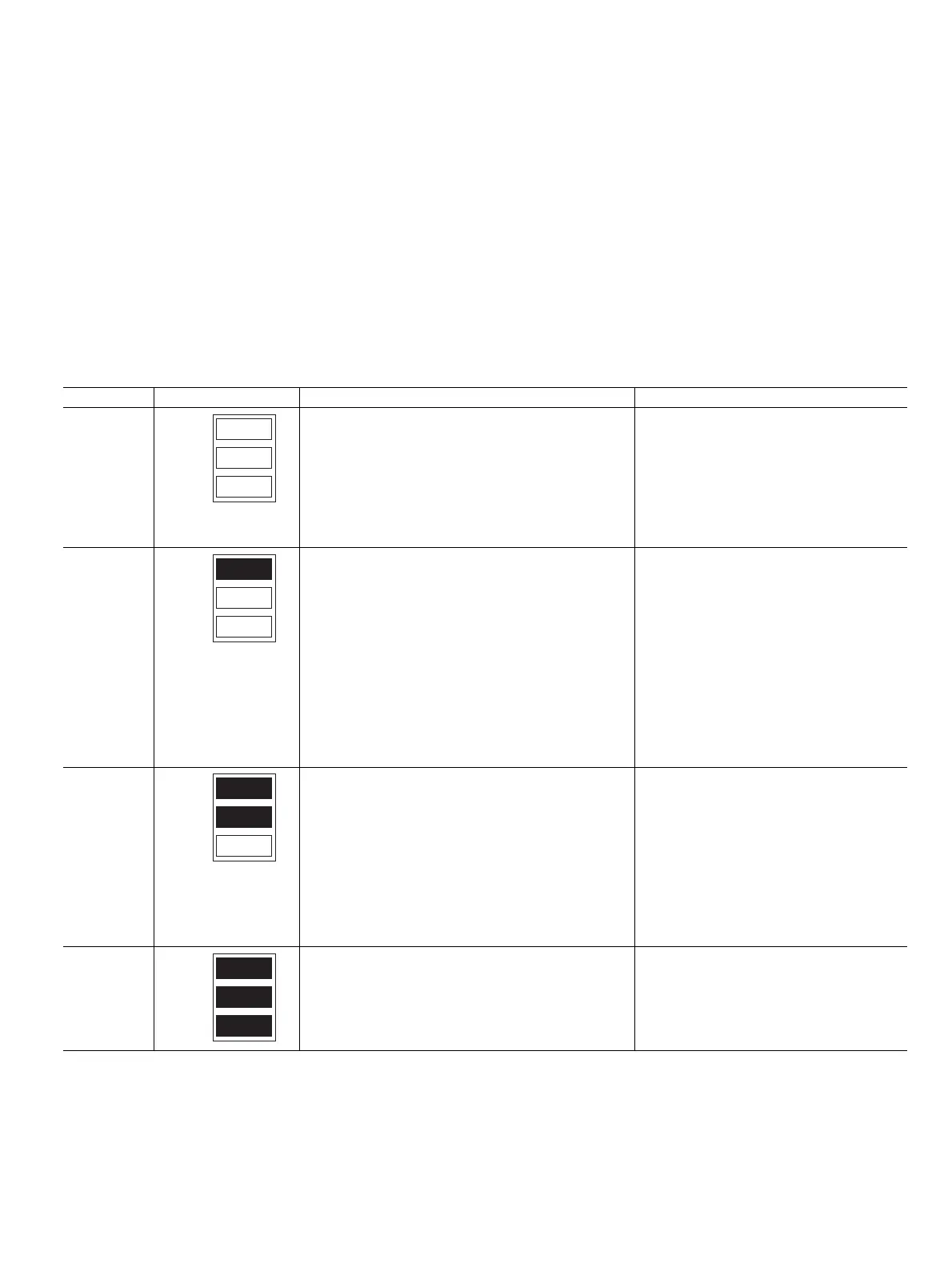

Level Function Keys Template Functionality

Base 0 Single loop

Single loop with remote setpoint

Process alarms

Basic setpoint switching

Basic control

— Analog PID

— On / Off or time proportioning

—Auto tune

— Split output control

Standard 1 Auto / Manual station low signal selection

Auto / Manual station digital signal selection *

Analog backup station low signal selection

Analog backup station digital signal selection *

Single indicator / manual loader

Dual indicator / manual loader

Standard setpoint switching *

Standard control

— Gain scheduling

— Motorized valve control †

Output tracking

Logic

Math

Custom linearizers

Delay timers

Real time alarms

Template customization

Extended 2 Single loop with feedforward

Single loop with feedforward and remote setpoint ‡

Cascade

Cascade with remote setpoint ‡

Cascade with feedforward ‡

Ratio controller (internal ratio)

Ratio controller (external ratio) ‡

Ratio station (internal ratio)

Ratio station (external ratio) ‡

Tot a l iza t i on

Advanced control

— Feed forward

— Predictive control

— Adaptive control

Historical trending

Display customization

Dual Loop 3 Dual loop – local / local ‡

Dual loop – remote / local ‡

Dual loop – remote / remote ‡

Recommended I/O Build: * Basic + option board 1, † Basic + option board 1a, ‡ Basic + option boards 1 and 2

Fig. 1: Overview of template options

Loading...

Loading...