54

Installation and commissioning guide

2750 515-1 EN, REV. 14, 2020-06-26

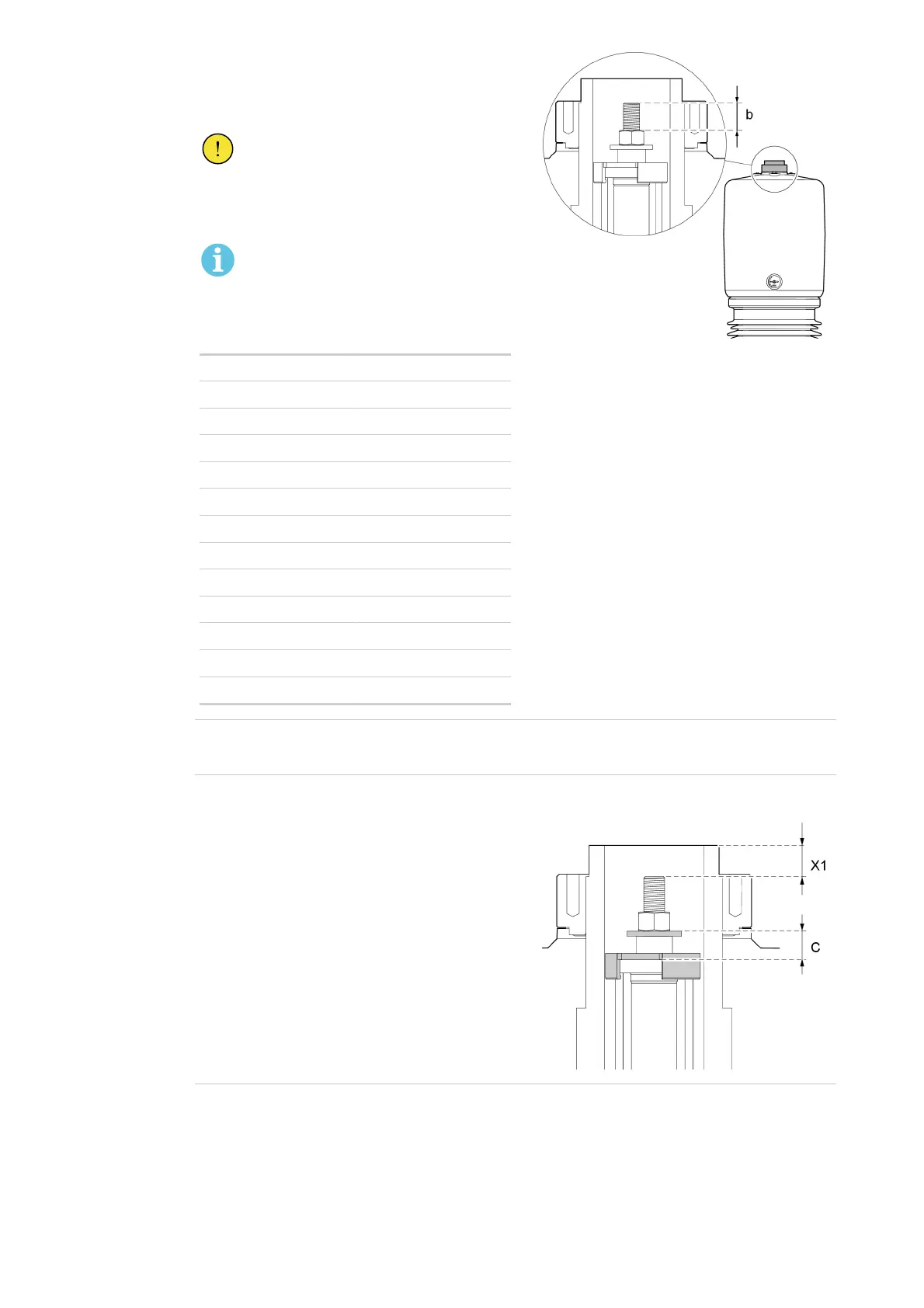

3. Turn the nut clockwise until you get the correct

extension (b).

Distance (b) = (a) + extension, refer to the table.

CAUTION!

Make sure that you do not overtighten

the nut. Use a torque wrench set to

140 Nm.

NOTE!

One turn of the nut corresponds to a

2 mm extension of the draw rod.

Type Extension

GOE 250 - 210 3.5 mm ±1.0

GOE 380 - 300 3.5 mm ±1.0

GOE 650 - 500 5.0 mm ±1.0

GOE 950 - 650 7.0 mm ±2.0

GOE 1050 - 750 9.0 mm ±2.0

GOE 1175 - 850 9.5 mm ±2.0

GOE 1300 - 1050 12.0 mm ±2.0

GOE 1425 - 1150 12.0 mm ±2.0

GOE 1550 - 1175 15.0 mm ±2.0

GOE 1675 - 1300 15.0 mm ±2.0

GOE 1800 - 1360 15.0 mm ±2.0

GOE 2550 - 1600 18.0 mm ±2.0

GOE 2550 - 1675 18.0 mm ±2.0

G005050

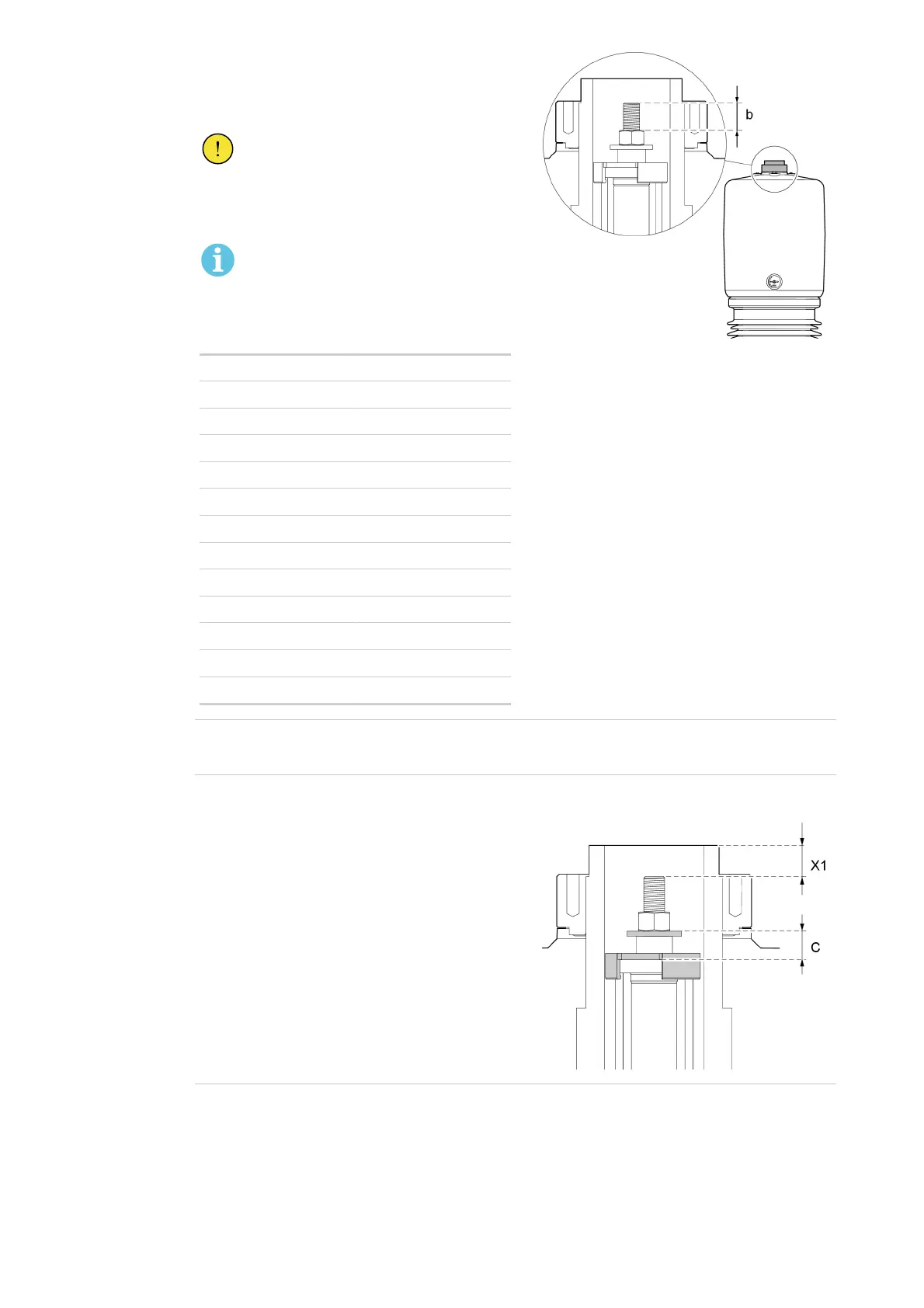

4.

Make sure with a torque wrench that the nut is tightened with a torque of more than 70 Nm and less

than 140 Nm.

5.

When installing the bushing at site:

1. Measure the values (X1) and (c).

2. Record the values in Measurement record,

page 87, for future reference.

Keep the document with the substation

documentation.

G006758

End of instruction

Loading...

Loading...