OI-LLT100-EN Rev. D | User Guide 33

CAUTION Property damage

See note “Securing the housing cover in flameproof/

explosion proof areas” on page 8

7. Power on the LLT100.

At power-on, the sensitivity of the LLT100 through-the-glass

(TTG) interface goes through a calibration. For the TTG to work

properly, it is mandatory that the housing cover be correctly

tightened before power-on.

NOTICE

After power-on, wait at least 30 seconds before

operating the TTG display.

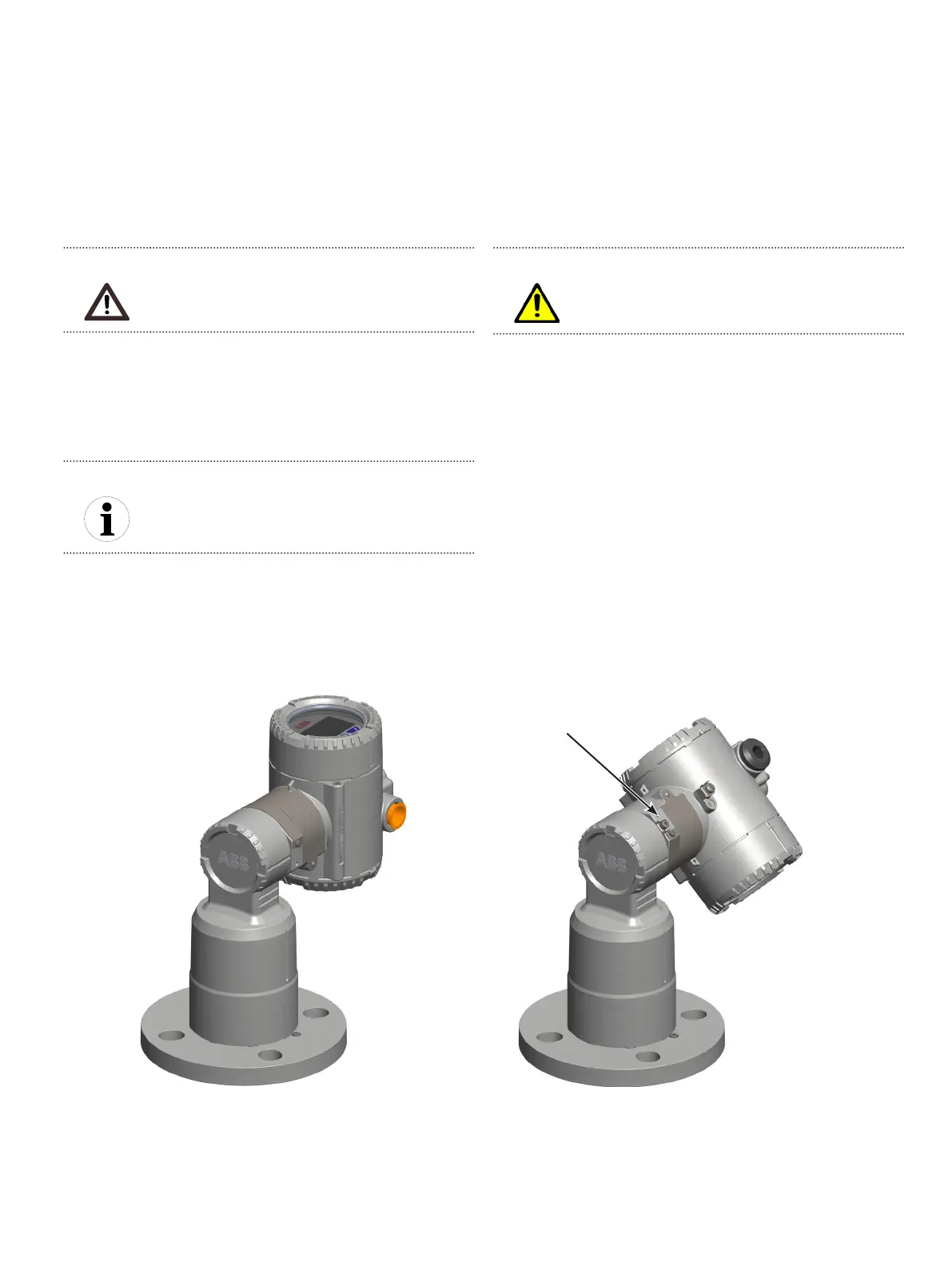

11.5 Rotating the LCD housing

To improve field access to the wiring, or LCD visibility, you may

rotate the LLT100 housing anywhere between –45° and +90°

from its initial position, and fixed in any of these positions.

A stop prevents the housing from being rotated too far.

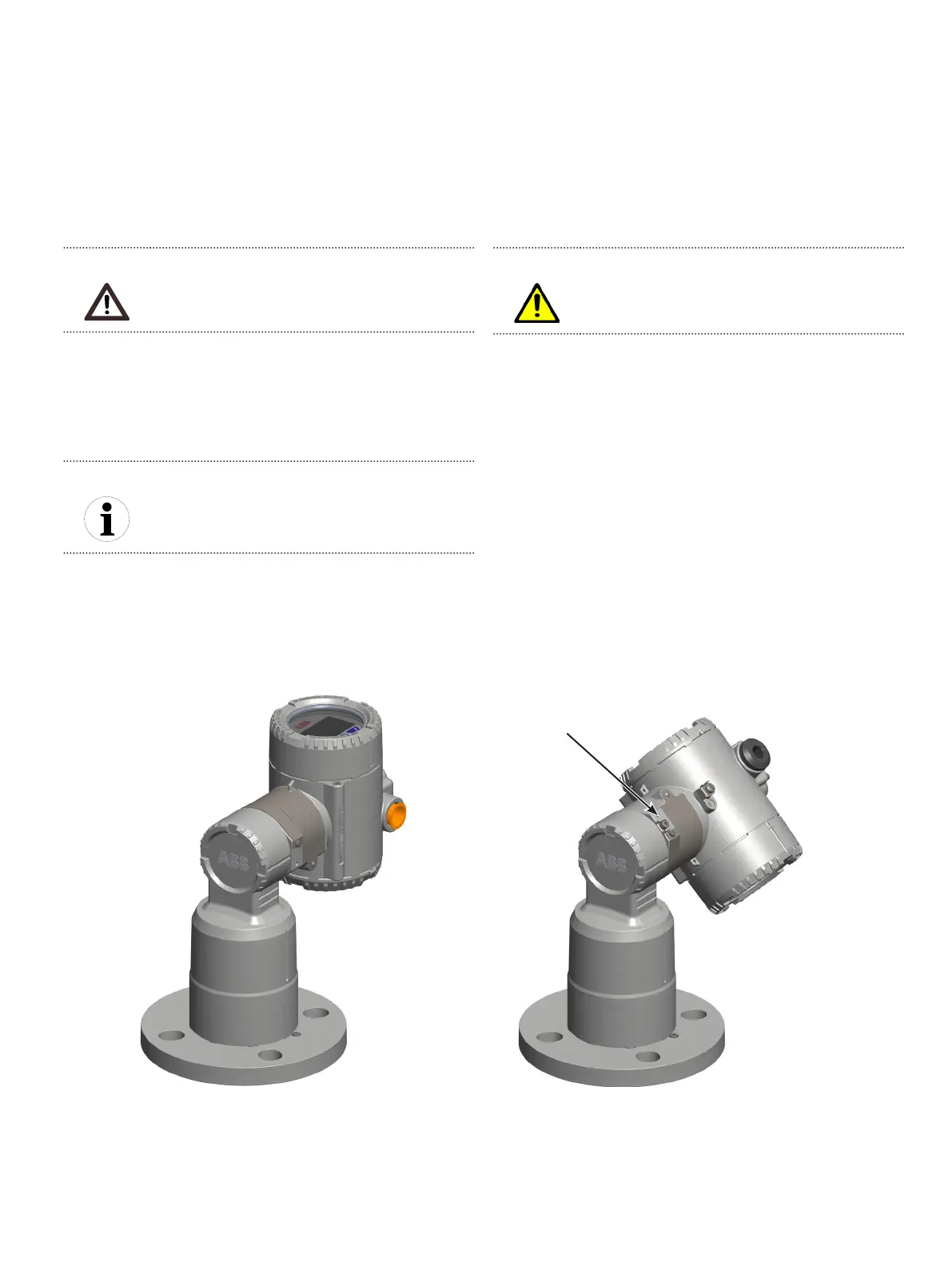

Figure23 Rotating limits of the LLT100 housing

Housing stop

tang-screw

+90° –45°

WARNING Property damage

Trying to turn the housing beyond the limits indicated

previously may permanently damage the instrument.

To rotate the housing:

1. With an Allen key, unscrew the housing stop tang-screw by

NO MORE than one turn (do not pull out the screw).

2. Position the housing in a way that is optimal to you (between

–45° and +90°). The tang-screw rotates with the housing.

3. Once the housing is in the proper position, tighten the stop

tang-screw.

11.6 Selecting installation material

The LLT100 is delivered as an autonomous assembly.

– Gaskets, washers, bolts and nuts are not included. Make sure

to procure all bolts, nuts and washers selected according to

the process and/or applicable national standards.

– Select application-specific gaskets, i.e. gaskets that complies

with the ASME B16.5 standard or the standard that you require.

– The instrument gasket and flange are to be selected

according to the application service conditions.

Mounting depends on the flange and process type. The

instrument can be bolted directly onto a flange or bracket.

– Make sure to follow the mounting setup as illustrated in

Figure 20 and Figure 21 on page 36.

Loading...

Loading...