20

EN

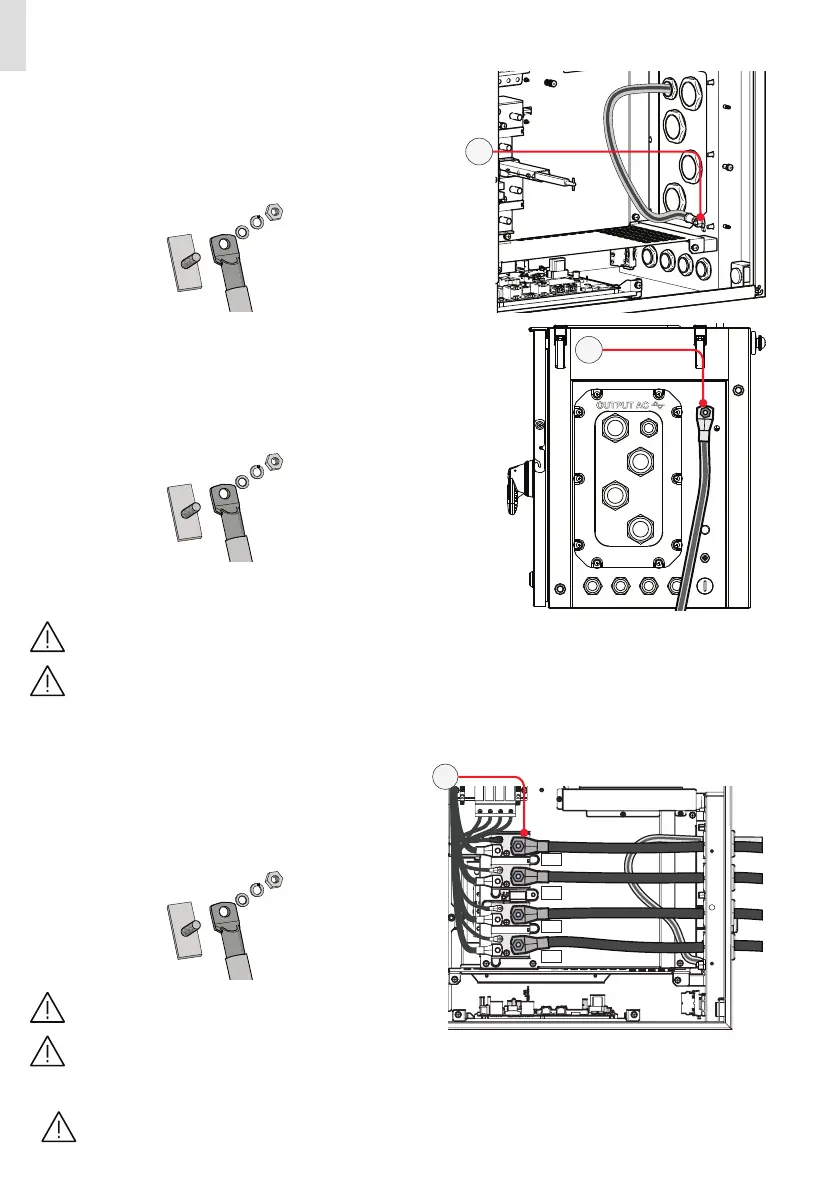

• Depending on the earth connection method (internal (25) or external (10)) follow the procedures described below:

INTERNAL EARTH CONNECTION:

• Pass the protective earth cable trought the proper cable gland on

the AC panel.

• Fix the protective earth cable lug to the protection earth connec-

tion point (int.) (25) using the washers and bolt pre-installed on

the M10 stud, as shown in the following diagram:

1 = cable lug

2 = flat washer

3 = spring washer

4 = M10 nut

1

2

3

25

EXTERNAL EARTH CONNECTION:

• Fix the protective earth cable lug to the protection earth connec-

tion point (ext.) (10) using the washers and bolt pre-installed on

the M8 stud, as shown in the following diagram:

1 = cable lug

2 = flat washer

3 = spring washer

4 = M8 nut

1

2

3

10

The cable lug must be installed with a minimum tightening torque of 21Nm.

Before connecting the inverter to AC or DC sources use a suitable multimeter to test the conductivity of the earth

connections between the protection earth connection point (ext.) (10) and a handles thread (04) on the housing of

power module.

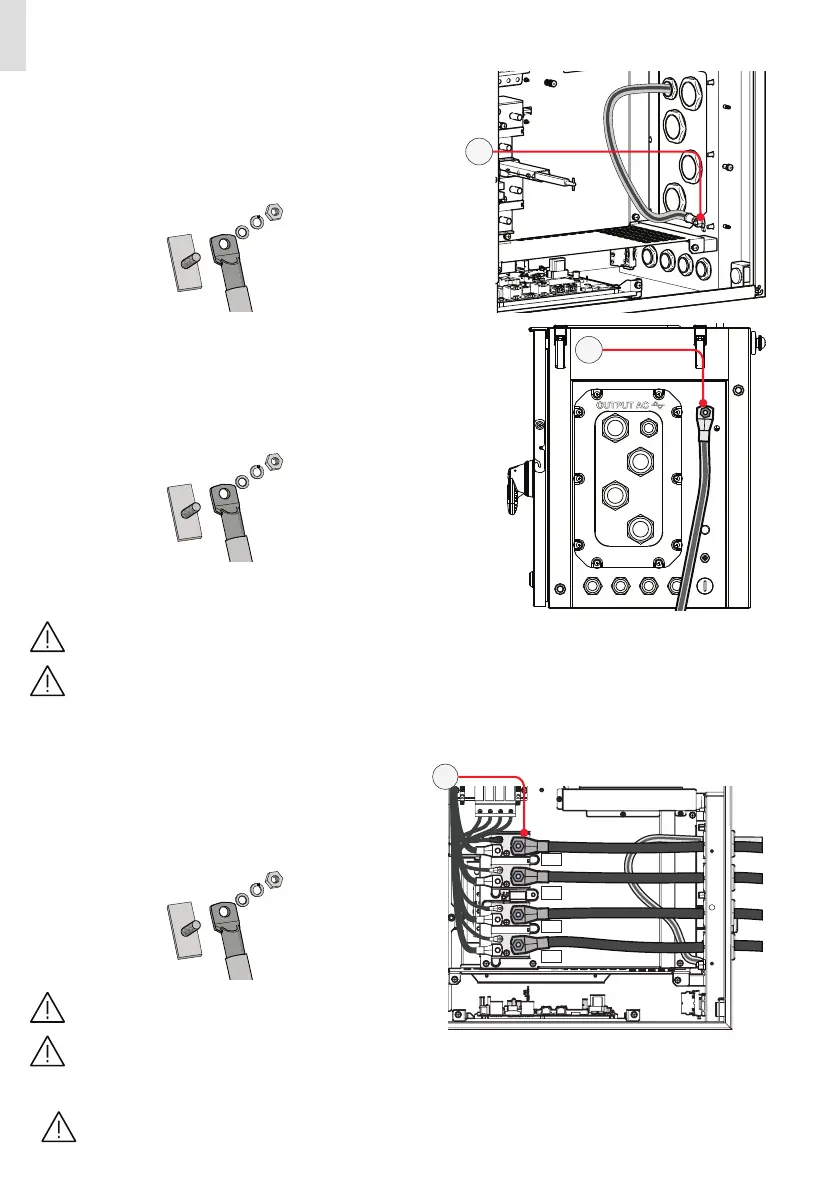

INTERNAL AC CONNECTION:

• Pass the phases cables through the cable glands on the AC

panel.

• Fix the phases and neutral (if required) cable lugs to the AC con-

nection busbars (21), paying attention to the corrispondence of

the phases with the labels, using the washers and the M10 nuts

pre-installed on the busbar as shown in the following diagram:

1 = cable lug

2 = flat washer

3 = spring washer

4 = M10 nut

1

2

3

The minimum recommended cross section for the

phases conductors is 70 mm².

The cable lugs must be installed with a tightening

torque of 25Nm.

21

• Check the tightness of the AC cable glands at the end of the installation.

Make sure the cable glands are properly sealed to ensure to keep IP65 protection degree.

Loading...

Loading...