diagrams and datasets as per the requirements. The SCT exports the SCD file back to a

SAM600 IED configuration tool where then a SAM600 configuration is finalized.

SAM600 supports the

bottom-up

engineering workflow.

2.2.1 SAM600 system configuration with PCM600

GUID-9790DA31-D7BB-4222-905D-8CBF3365C689 v1

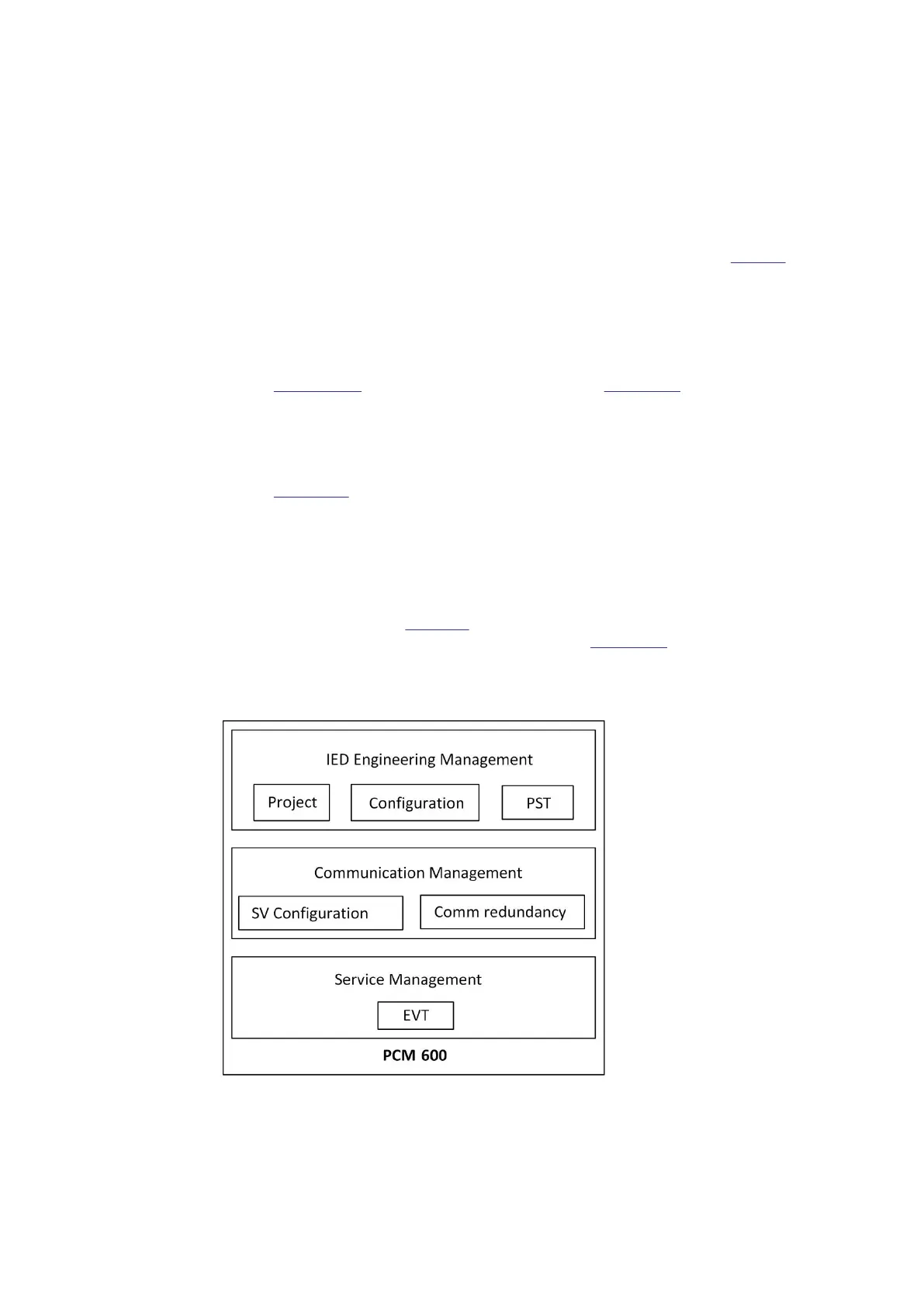

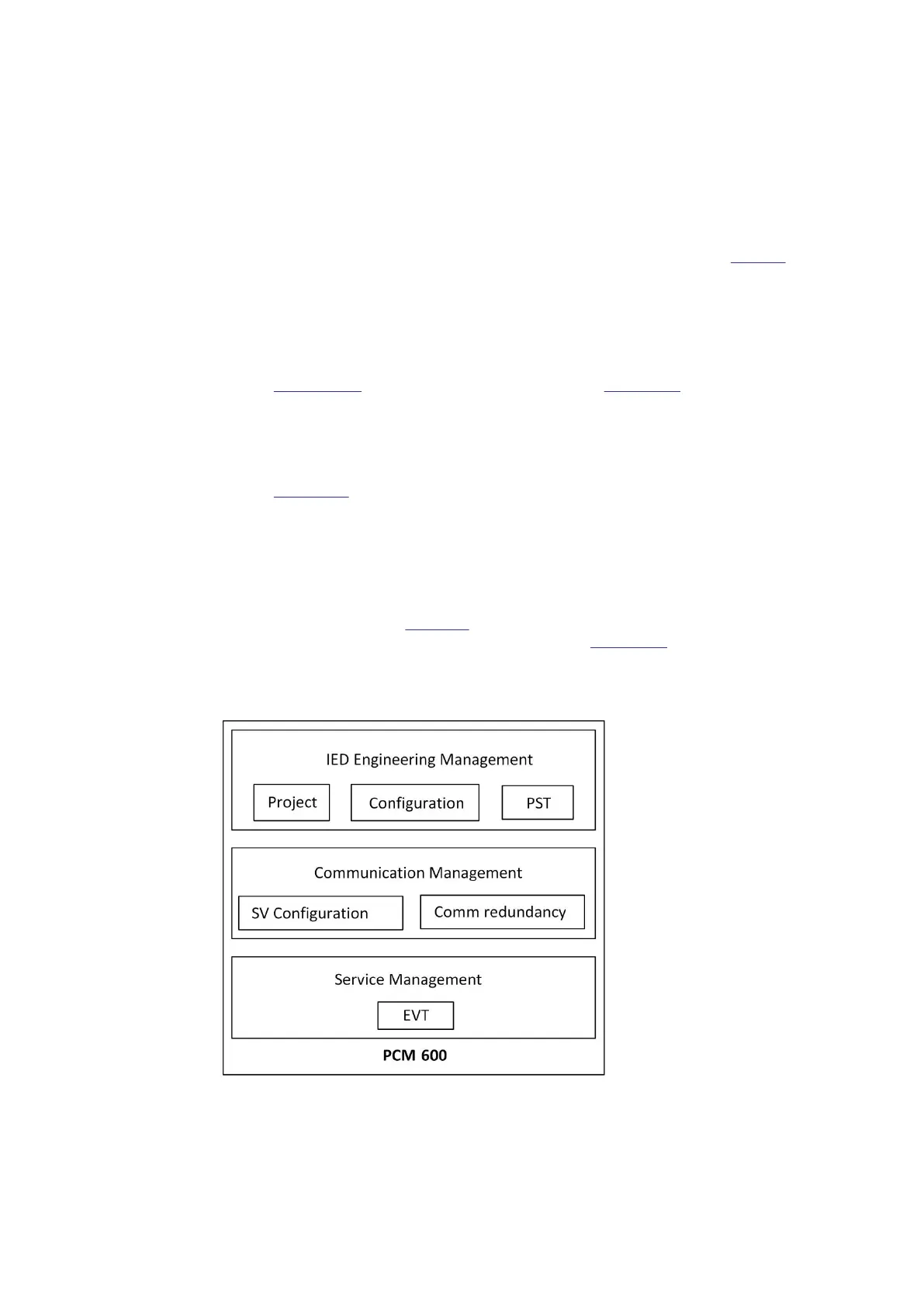

PCM600 is used for various tasks in a SAM600 system engineering process, see Figure 1.

• SAM600 system engineering management

• Organizing the bay SAM600 systems in the structure of the substation by defining

voltage levels and bays below the substation. A PCM600 project can have only one

substation.

• Configuring or updating the SAM600 modules by using the Configuration Wizard,

see

Section 4.4.1or Composition Upgrade Tool, see Section 5.3.

• Configuring communication settings per SAM600 module, such SAM600 system bus

(daisy chain or ring), and IEC 61850 process bus communication redundancy

configuration.

• Configuring the parameters and setting values for a SAM600 system itself and for

the process functionality by using the Parameter Setting Tool. For more information,

see

Section 5.1.

• Communication Engineering

• Sampled Values can be configured with the PCM600 built in SV Stream and Port

Configuration Tool.

• Service Engineering

• Listing the existing SAM600 system internal events and process events by using the

Event Viewer Tool, see Section 7.

• Interact with SAM600 system via commands, see Section 5.6.

IEC18000104 V1 EN-US

Figure 1: Organization of PCM600 in different management tasks

Section 2 1MRK 511 433-UEN B

Engineering tool set

6 SAM600 Process Bus I/O System

Engineering manual

© Copyright 2017 ABB. All rights reserved

Loading...

Loading...