Absolute Boilers ABS 1500-2000-2500-3000-4000

70

Max. 70 PSI air pressure to clean burner

11.1.5 Cleaning the burner assembly

CAUTION

Turn electrical o, then ensure gas has been shut o at the main shut o valve. Next purge all gas in the system

as per code. The burner may be hot, allow enough time to allow the boiler to cool before removing the burner tube.

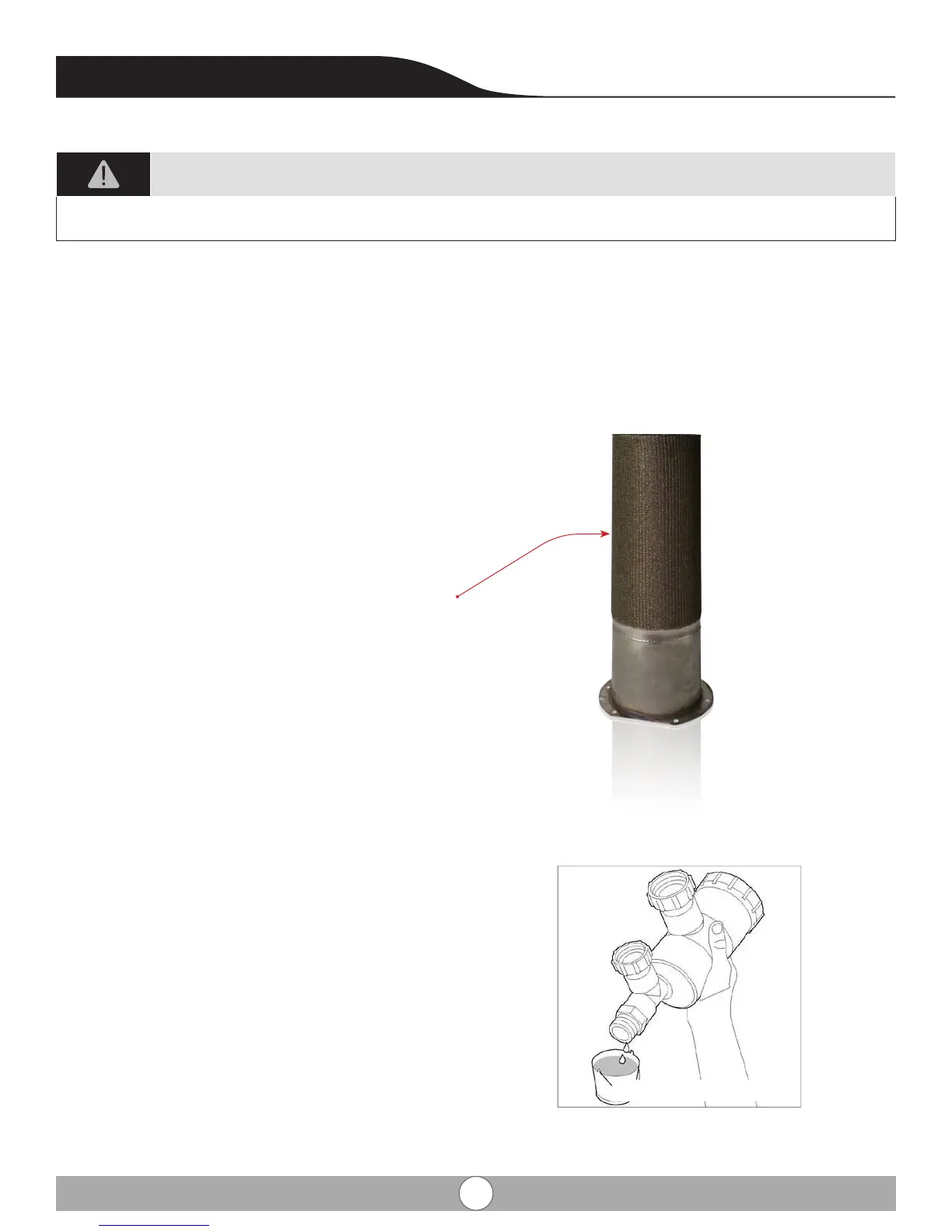

Upon removal of the burner tube, inspect it for any damage to the woven mesh and ensure no damage has been done

to the tube from heat. If the burner is in good condition, clean the burner assembly by using compressed air only –

between 30 – 70 psi [2-5 bar] with the nozzle positioned a min of 3/8” [10mm] away and towards the face of the burner.

If there is any damage to the mesh or tube, the burner must be replaced. Check the retaining bolts are tight. If the

burner is removed from the front plate ensure burner-retaining screws are tight on re-assembly

11.1.6 Cleaning the siphon

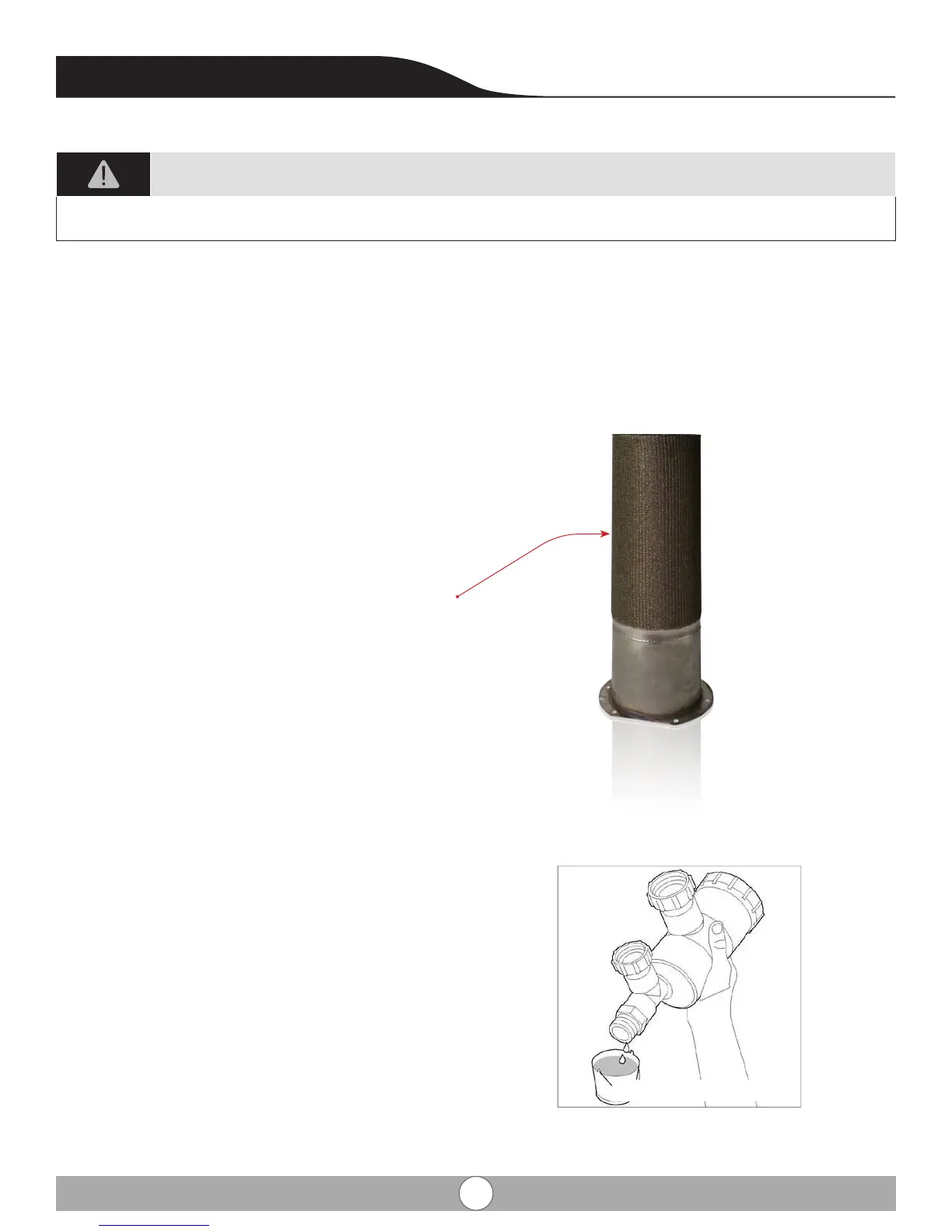

Remove the complete siphon (located underneath condensate

collector beneath the ue connection). Remove siphon, clean and

rell with clean water and re-t.

Fig. 35 – Condensate siphon assembly

Loading...

Loading...