Page 76 of 84

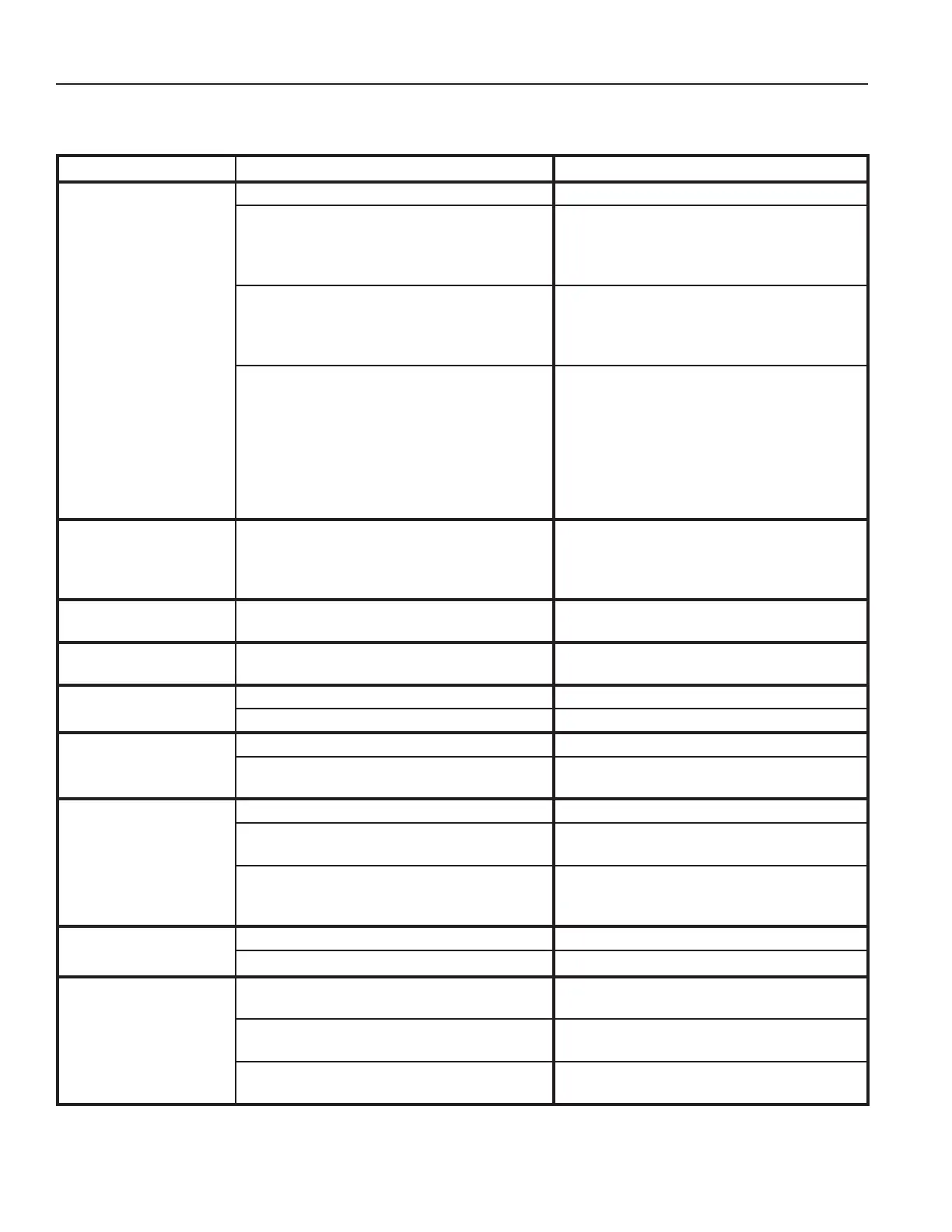

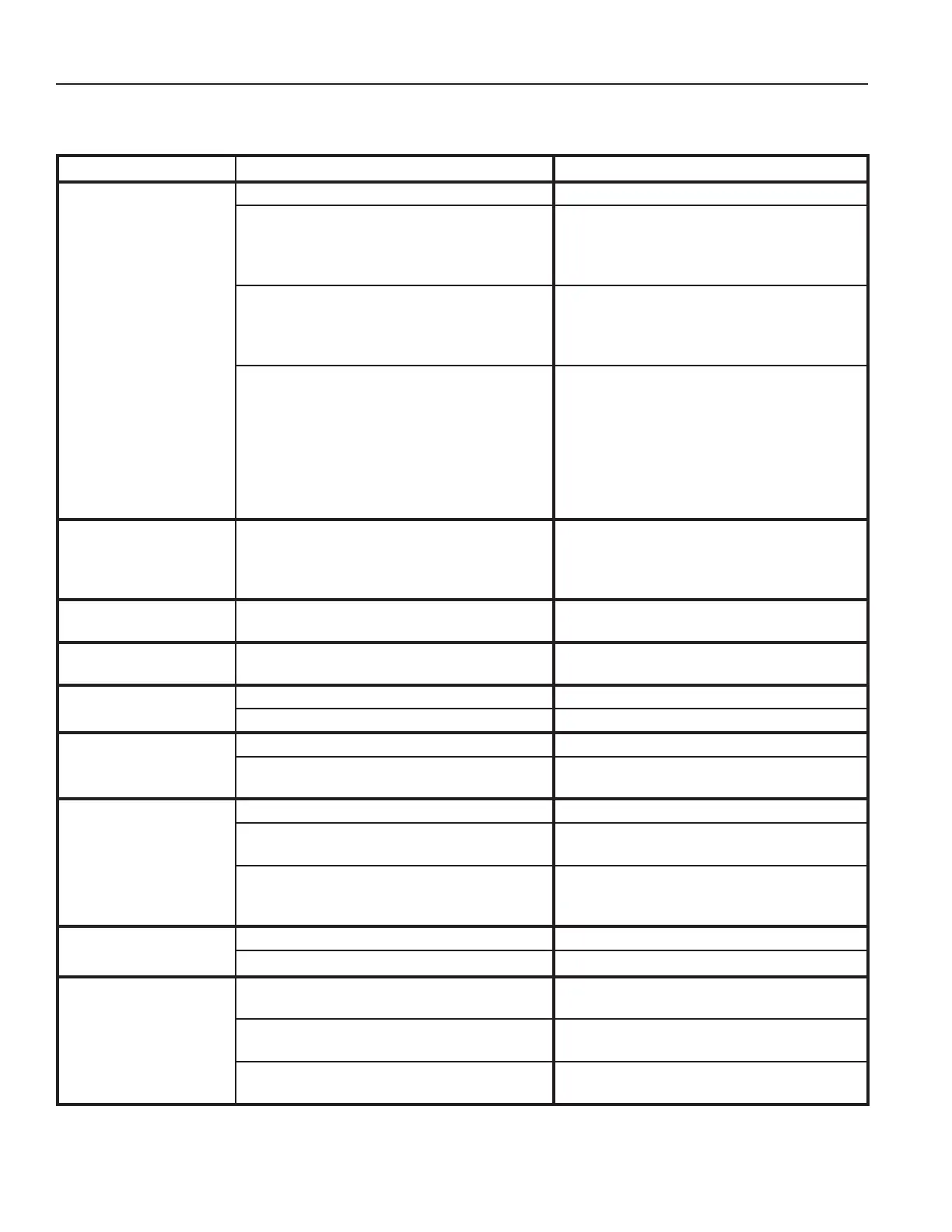

Problem Probable Cause Solution

No Fan Operation

No 24V control voltage Check for 24 VAC at control

No input pressure to control

Check alignment of capillary fitting

Schrader valve depressor must depress

Schrader valve enough to allow pressure

into capillary

Bad fan motor

Disconnect power, when P266 is used,

place a jumper from L1 to M1 and connect

power, if fan does not start, motor is bad

and should be replaced

Pressure transducer problem

Disconnect 6 pin connector from right side

of control, place a jumper wire between

third pin from the top and bottom pin on

the control (not the cable) If fan goes to

full speed, check for input pressure If it

has been determined there is adequate

pressure, the transducer is bad and the

control must be replaced

Fan Stops When

Pressure Reached

The High End Of The

Operating Range

Control is not wired correctly See wiring diagrams

No Fan Modulation

(On-O Operation)

Control is not wired correctly See wiring diagrams

Fan Starts At

Full Speed

Control is not wired correctly See wiring diagrams

Erratic Fan Operation

Control is not wired correctly See wiring diagrams

Dirty or blocked condenser coil Clean condenser coil

Fan Motor Is Cycling

On Thermal Overload

Dirty or blocked condenser coil Clean condenser coil

Wrong motor for fan speed

control application

Replace with motor approved for fan speed

control application

Erratic Pressure

Control

Defective regulator Replace defective part

Dirt causing regulator to bind

Disassemble regulator and clean internal

parts Install strainer

Power source to hot gas solenoid or

operation of the solenoid is intermittent

Determine if problem is caused by supply

voltage, solenoid or excessive MOPD, make

changes necessary to correct problem

Regulator Leakage

Dirt in regulator causing seat to remain open Clean regulator Install strainer

Worn or eroded seating surface on regulator Replace defective part

Regulator Hunting

(Chattering) With

Large Fluctuations

In Controlled Pressures

Regulator is oversized

Contact Addison for correctly

sized regulator

Regulator and liquid injection thermovalve

have control interaction

Increase superheat setting, dampen bulb

response by repositioning

Regulator and cylinder unloaders have

control interaction

Increase dierential between the controls

by lowering the regulator’s setpoint

Table 13.4: Variable Speed Head Pressure Control

PR Series Installation, Operation, and Maintenance Manual

Loading...

Loading...