The Advanced

®

Model 3250/4250 Service Manual

48

1. Turn on the instrument. If there is a

Supervisor/Operator keyswitch, turn it to

the Supervisor position (if required).

Place an empty sample tube in the sample

well.

2. Press TEST. Press < or > to select

“Head Up/ Down Test”, and then press

START.

3. Place an empty sample tube into the

freezing chamber.

4. At “[START] Test [STOP]”, press

START.

The head should move continually up and

down.

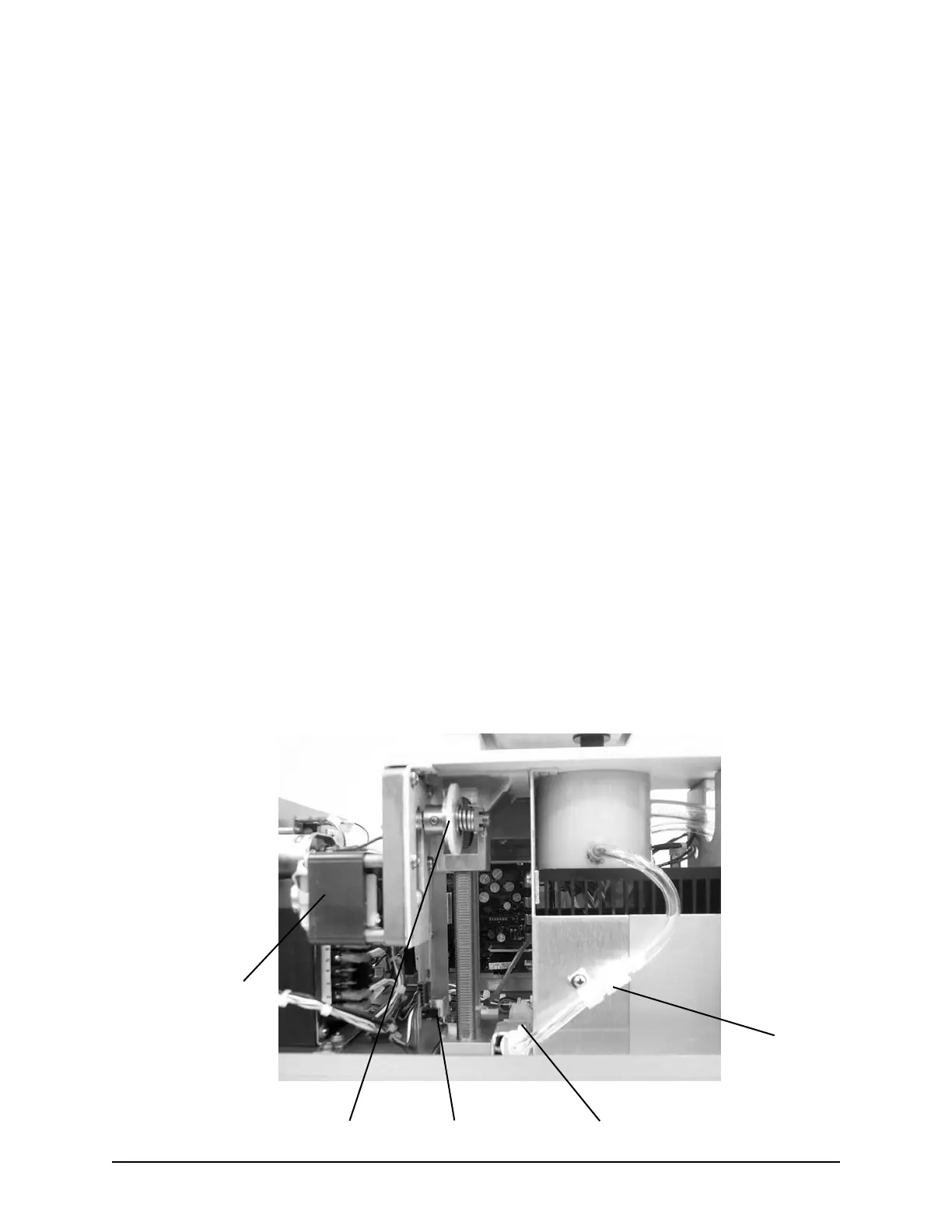

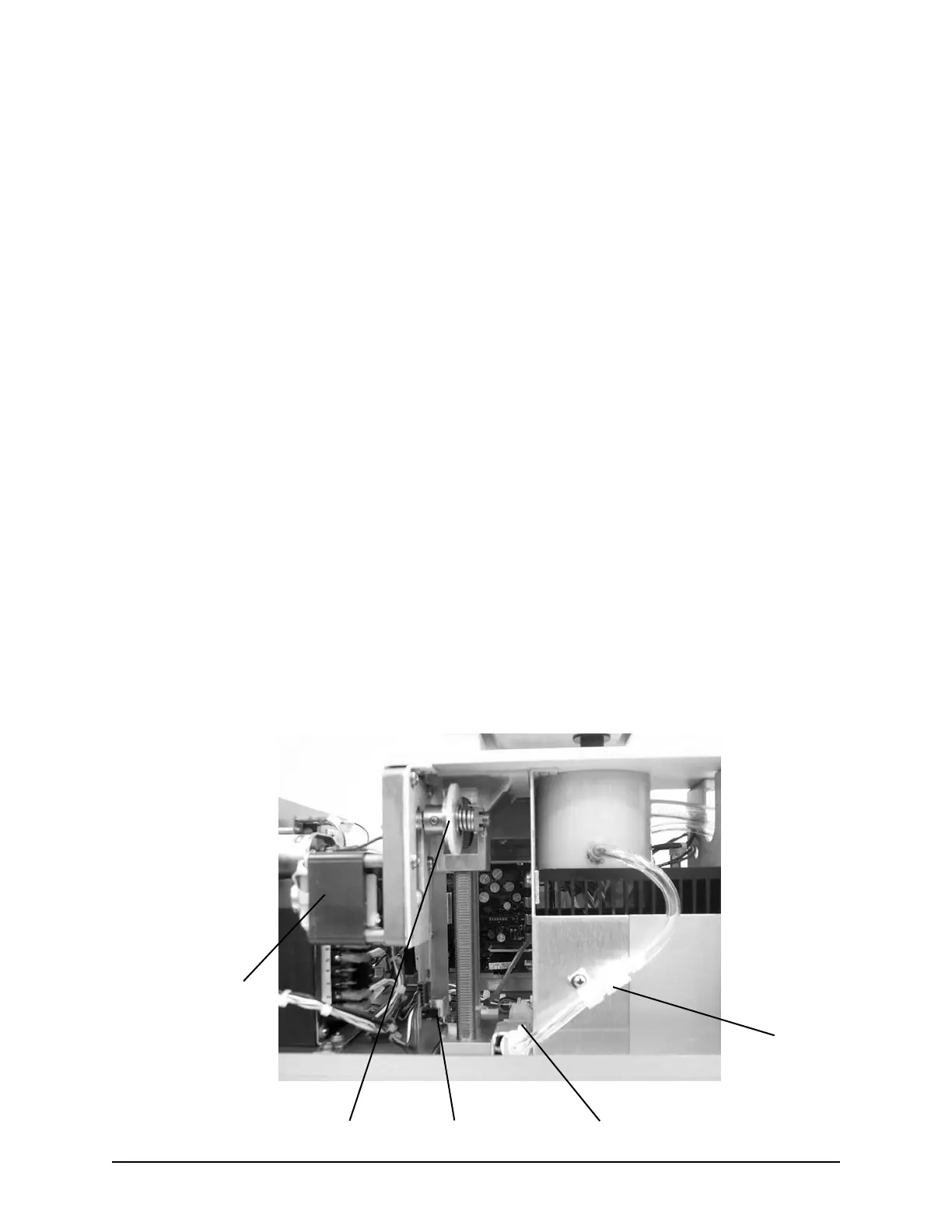

Use this test to ensure the following compo-

nents are working properly:

• The motor (A) is running.

• The gears (B) are turning properly.

• The sensors (C) are detecting the head-up

and head-down conditions.

• The sample well fluid passage (D) is not

obstructed by debris, and the pump is mov-

ing the heat transfer fluid into the freezing

chamber.

Note: If the sample well fluid passage is

obstructed, disassemble and clean the

sample well following the instructions

found earlier in this section. Also,

examine the one-way check valve (E)

to make sure it is not stuck open or

closed.

Note: Your instrument is equipped with a

series of diagnostic LEDs on the main

application board PCB605 to allow

visual identification of drive signals

and sensor activation.

• The yellow LEDs marked “Drive

Up” and “Drive Dn” indicate that

the control electronics have issued a

command to the head motor relays.

• The red LEDs marked “Head Up”

and “Head Dn” indicate that the

corresponding optical sensor has

been tripped.

A

B

C

D

Head Up/Down Test

E

Loading...

Loading...