Do you have a question about the Advanced Instruments OsmoTECH PRO and is the answer not in the manual?

Remove the rear and side enclosure as explained in OsmoTECH PRO Disassembly and Reassembly.

Remove the cable clamp [A] securing the C10 sample probe cable and C11 block probe cable.

Unplug the C10 and C11 connectors from the control PCB.

Disconnect B1-B4, B6-B10 connectors on the motor/sensor cable harness.

Disconnect A1-A4 connectors on the cooling system harness from mating connectors.

Rest the instrument on its back side before proceeding.

Remove the two screws [B] securing the power supply and controls assembly to the chassis bottom.

Place the instrument in the upright position.

Remove the two screws [C] securing the power supply and controls assembly to the chassis rear.

Slide the power supply and controls assembly out of the base assembly.

Remove four socket head cap screws and washers [D] from the mounting bracket.

Carefully slide the osmometer module out of the instrument.

Remove hex nut and washer [E] securing SPG and BPG ring terminals.

Remove four socket head cap screws and washers [F] mounting the module bracket.

Lift the osmometer module off of its mounting bracket.

Remove four screws [F] securing cooling fan, finger guard, and diverter to heatsink.

Disconnect the sample well drain tubing [G] from the drain tube [H].

Remove four socket head cap screws [I] securing cooling assembly to mounting block.

Remove block probe, thermo-electric, and solenoid cables from cable clamps [J].

Detach the cable clip [K] from the thermo-electric wire leads.

Carefully lift the sample cooling assembly out of the osmometer module assembly.

Record block probe cable position and insertion depth before removal.

Fill the syringe with thermal grease.

Inject grease into the block probe hole [M] while withdrawing syringe tip.

Record the four-digit resistance value [M] listed on the block probe cable.

From the main menu, press SETTINGS > PROBE RESISTANCE.

Log in to your account to access settings.

Enter the resistance value [M] previously recorded for the block probe cable.

Recalibrate the instrument after replacing the block probe.

Secure the sample cooling assembly and cable clip using screws and washers [1].

Lift up the sample well mounting block until the sample tube is below the stripper bracket.

Carefully lower the movable plate securing the sample probe until it enters the sample tube.

Mount the replacement osmometer module using screws and washers [F].

Secure SPG and BPG ring terminals using hex nut and washer [E].

Slide the osmometer module into the instrument.

Mount the osmometer module mounting bracket using screws and washers [D].

Place the instrument in an upright position.

Plug A1-A4 connectors on the cooling system harness into their mating connectors.

Plug B1-B4, B6-B10 connectors on the motor/sensor cable harness.

Plug the C10 and C11 connectors into the control PCB.

Secure C10 and C11 probe cables to the power supply assembly with clamp and screw [A].

Reassemble the instrument following disassembly instructions.

When powered on, press SETTINGS > PROBE RESISTANCE.

Change the block probe resistance value to match the previously recorded value.

Calibrate the instrument as per the service guide.

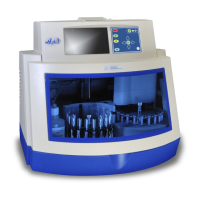

The OsmoTECH® PRO is a multi-sample micro-osmometer designed for precise measurement of osmolality in various samples. This document outlines a replacement procedure for the block probe (p/n 222123R), a critical component for the instrument's operation. The device is intended for use in conjunction with service procedures requiring access to its internal components, ensuring accurate and reliable performance.

The OsmoTECH® PRO operates by measuring the freezing point depression of a solution, which is directly proportional to its osmolality. The block probe is a key sensor in this process, responsible for accurately detecting the temperature changes during the freezing point determination. The instrument is designed for multi-sample analysis, indicating its capability to process multiple samples efficiently, likely through an automated or semi-automated system. The replacement procedure detailed in the manual ensures the continued accuracy and functionality of this critical measurement.

While specific numerical specifications like measurement range or accuracy are not directly provided in this excerpt, the document implies several technical aspects:

The manual primarily focuses on maintenance rather than daily operational usage. However, some usage features can be inferred:

The document is a detailed guide for a specific maintenance procedure, highlighting several key maintenance features:

| Brand | Advanced Instruments |

|---|---|

| Model | OsmoTECH PRO |

| Category | Measuring Instruments |

| Language | English |

Loading...

Loading...