5

Pre-Wired

Pre-wired units are supplied with a 16 AWG cable(s) with 3-wire grounded USA 115 volt plug for incoming

power and 3-wire grounded receptacle cords for all control relay outputs also 16 AWG.

Conduit

Conduit units are predrilled at the factory and supplied with conduit knockouts for easy hard wiring to supplied

detachable connectors on the relay card(s) located in the lower section of the controller. Remove the screws

of the lower panel for access.

NOTES:

1. Do not drill holes in upper section of enclosure.

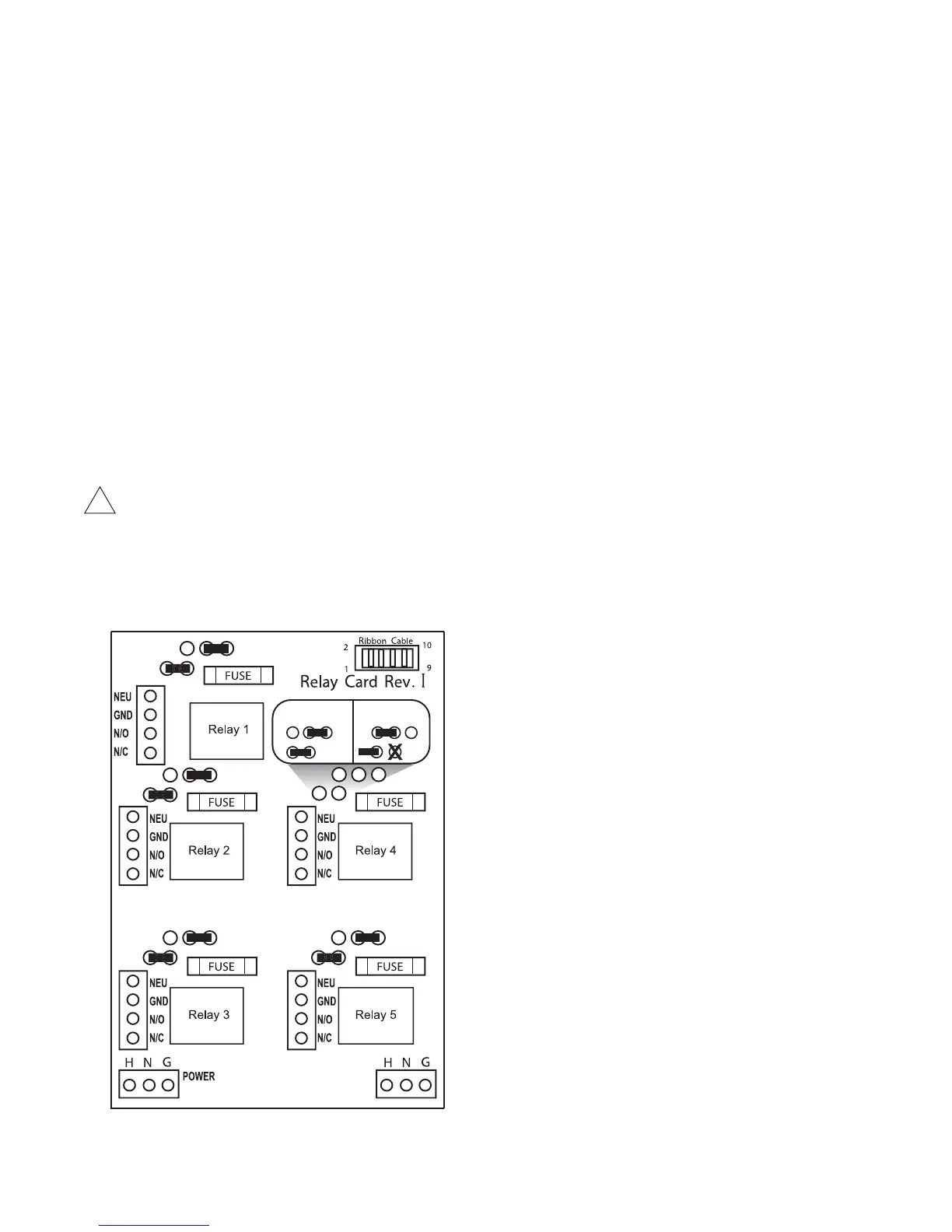

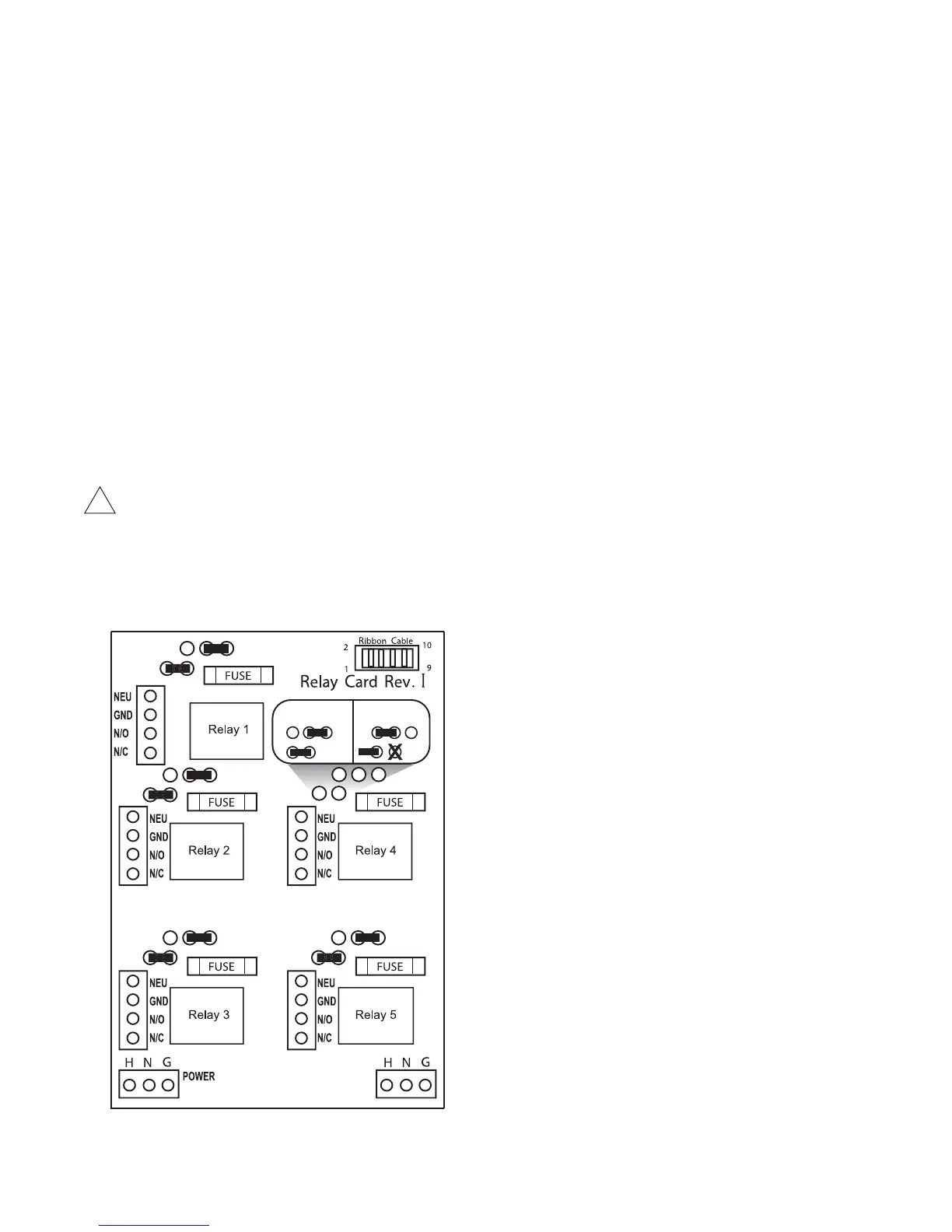

2. All relays provide a N.O. and N.C. output.

7KHFRQWUROIXQFWLRQWKDWDFWLYDWHVHDFKUHOD\RXWSXWLVSUHFRQ¿JXUHGDWWKHIDFWRU\

based on the options selected. To change relay activation, see on page 30.

4. See page 34 for common bleed / blowdown valve wiring.

5HIHUWRODEHOLQVLGHORZHUSDQHOFRYHUIRUVSHFL¿FUHOD\ERDUGFRQ¿JXUDWLRQVXSSOLHG

5HOD\VFRQ¿JXUHGDV³GU\FRQWDFW´VKRXOGRQO\KDYH'&YROWDJHUDQWKURXJKWKHP7KH*1'

FRQQHFWLRQSRLQWUHSODFHVWKH1(8ZKHQFRQ¿JXUHGIRUGU\FRQWDFW([DPSOH8VH*1'DQG12

for a normally open dry contact relay output.)

WARNING:,IMXPSHUVDUHQRWFRQ¿JXUHGIRUGU\FRQWDFWOLQHYROWDJHZLOOEHVXSSOLHG

Relay Card Wiring

Rev. I Relay Card

!

Powered relay Dry contact

INPUT

Loading...

Loading...