4

Chemical Feed Timers

Chemical feed timers are designed to automate the addition of various chemicals by activating a relay output.

Multiple timers can be supplied depending upon the model number and each timer will include a relay output.

All timers can be programmed to be one of the following types.

1. Pulse Time - Accepts pulses from a make-up water meter (supplied separately). It can accumulate

1-9999 gallons before activating the timer to run.

2. Feed with Bleed - Activates the relay output simultaneously with the bleed and limits the amount

of time the relay output will be on during the bleed cycle.

3. Feed after Bleed

for the set percentage of that bleed cycle.

4. Recycle

cycle time.

5. 28 Day - The timer is based on a 28 day cycle with four independent programmable feed cycles

with prebleed and bleed lockout settings.

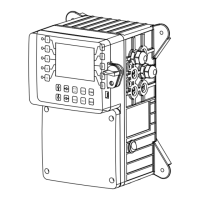

II. Installation

Electrical Wiring

VAC at 47 to 63 Hz on the incoming wiring. Each output relay is individually protected with a replaceable fuse.

Relay outputs will equal incoming line voltage.

CAUTION

1. There are live circuits inside the controller even when the power switch on the front panel is in

the OFF position. Never open the front panel without rst disconnecting power from the outlet.

Prewired controllers are supplied with an 8 foot, 18 AWG power cord with USA style plug. A #1

Phillips driver is required to open the front panel.

2. Low voltage signal wires (probes, ow switch, water meter, etc.) should never be run

in conduit with high voltage (like 115VAC) wires.

3. Never attempt to land connections to the controller without rst disconnecting power from the outlet.

4. Do not block access to disconnect power during mounting and installation.

5. The controller should be connected to its own isolated circuit breaker, and for best

results, the ground should be a true earth ground, not shared. Any attempt to bypass the grounding

will compromise the safety of users and property.

6. The electrical installation of the controller must be performed by trained personnel only and

conform to all applicable National, State and Local codes.

7. Operation of this product in a manner not specied by the manufacturer may result in damage

to equipment or persons.

8. Avoid mounting in locations that expose the controller to direct sunlight, vapors, vibration,

liquid spills or extreme temperatures; less than 0°F (-17.8°C) or greater than 120°F (50°C).

EMI(electromagnetic interference) from radio transmissions and electric motors can also cause

damage or interference and should be avoided.

! !

Loading...

Loading...