10

B. Boiler

Standard boiler electrodes have a MNPT stainless steel bushing and are supplied with a FNPT cross

& hold). For a successful installation, it is critical to observe the recommended distances and pipe sizes

provided in the installation drawings.

the electrode is exposed to water and not steam. Properly installed and adjusted, this device will prevent

NOTES:

1. Install a fully ported type valve between the electrode and the boiler. This

allows the electrode to be isolated for removal and cleaning.

2. A ushing line and 1/4 turn type ball valve should be installed in the bottom

of the cross to periodically “ush” sediment from the electrode chamber.

3. Make sure the alignment arrows on the probe end up parallel to the ow for

best performance.

WARNINGS:

1. The probe must be fully immersed in the system water to read correctly.

Steam ashing will result in incorrect readings.

2. Do not exceed a maximum water temperature of 436°F (224°C)

3. Do not exceed a maximum pressure of 350 psi (24.1 bar)

4. A throttling device must be installed downstream from the electrode.

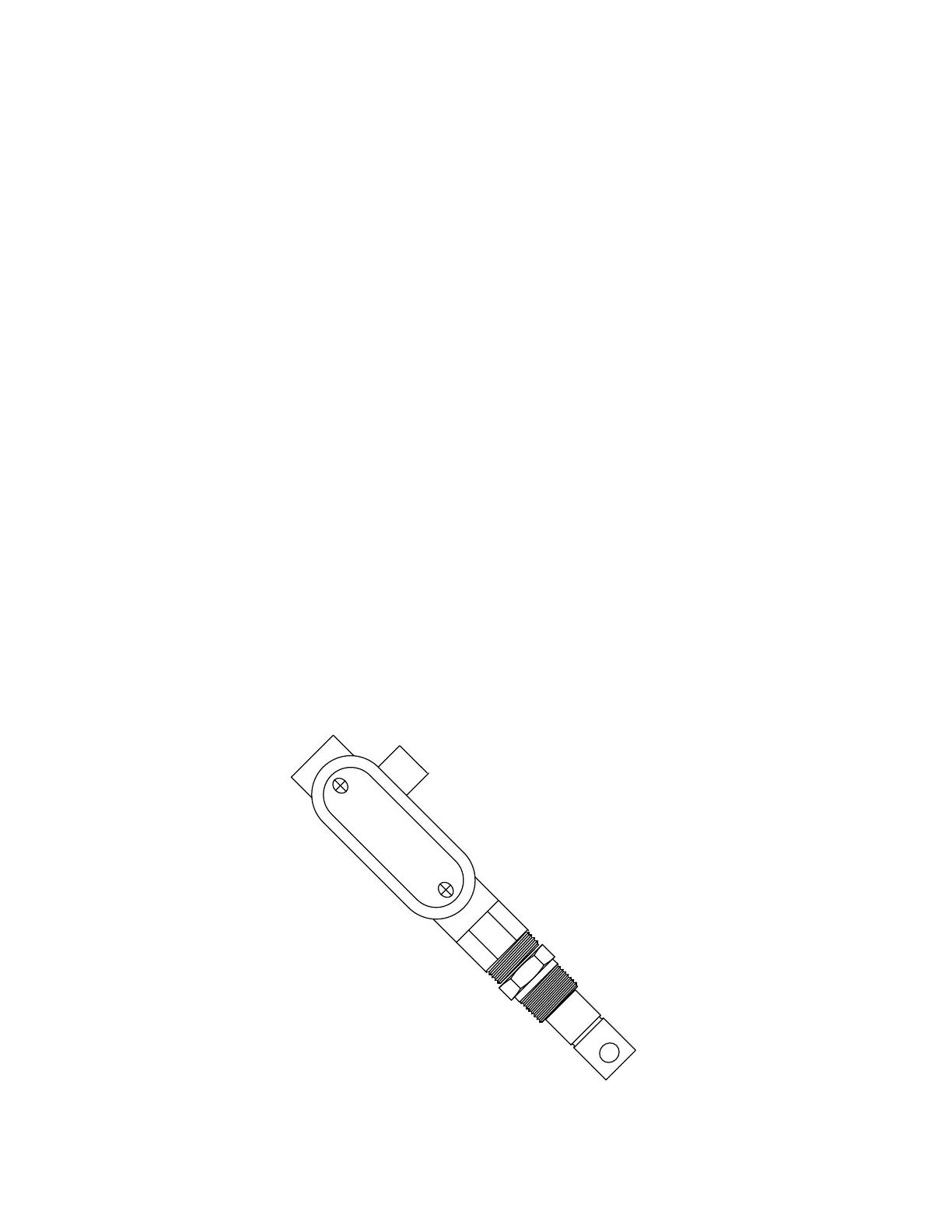

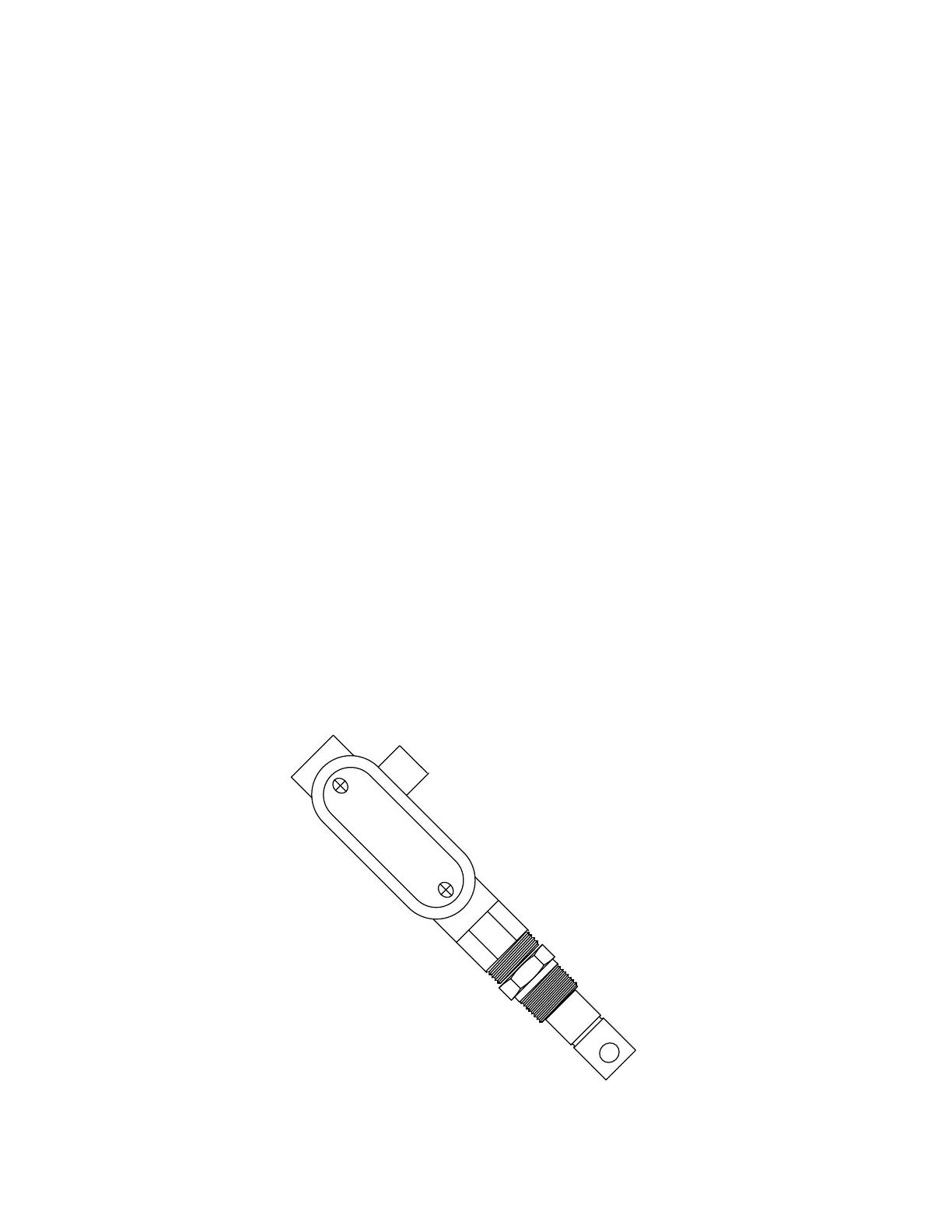

Boiler Conductivity Electrodes

BE-4RTD and BE-32

Wiring Note: BE-4RTD probes require a 6-conductor cable from controller to probe, BE-32 probes only

require a 2-conductor cable.

Loading...

Loading...