15

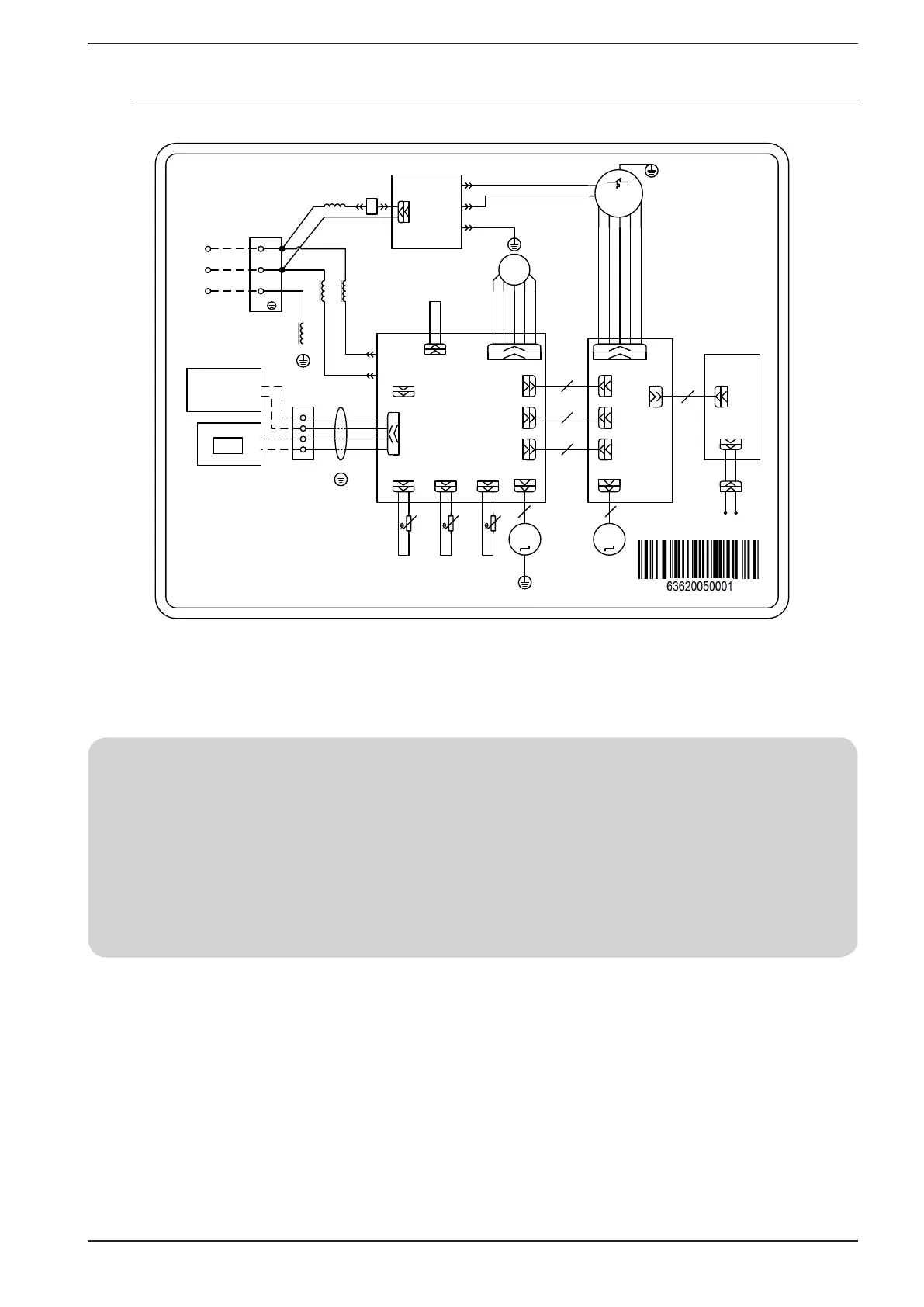

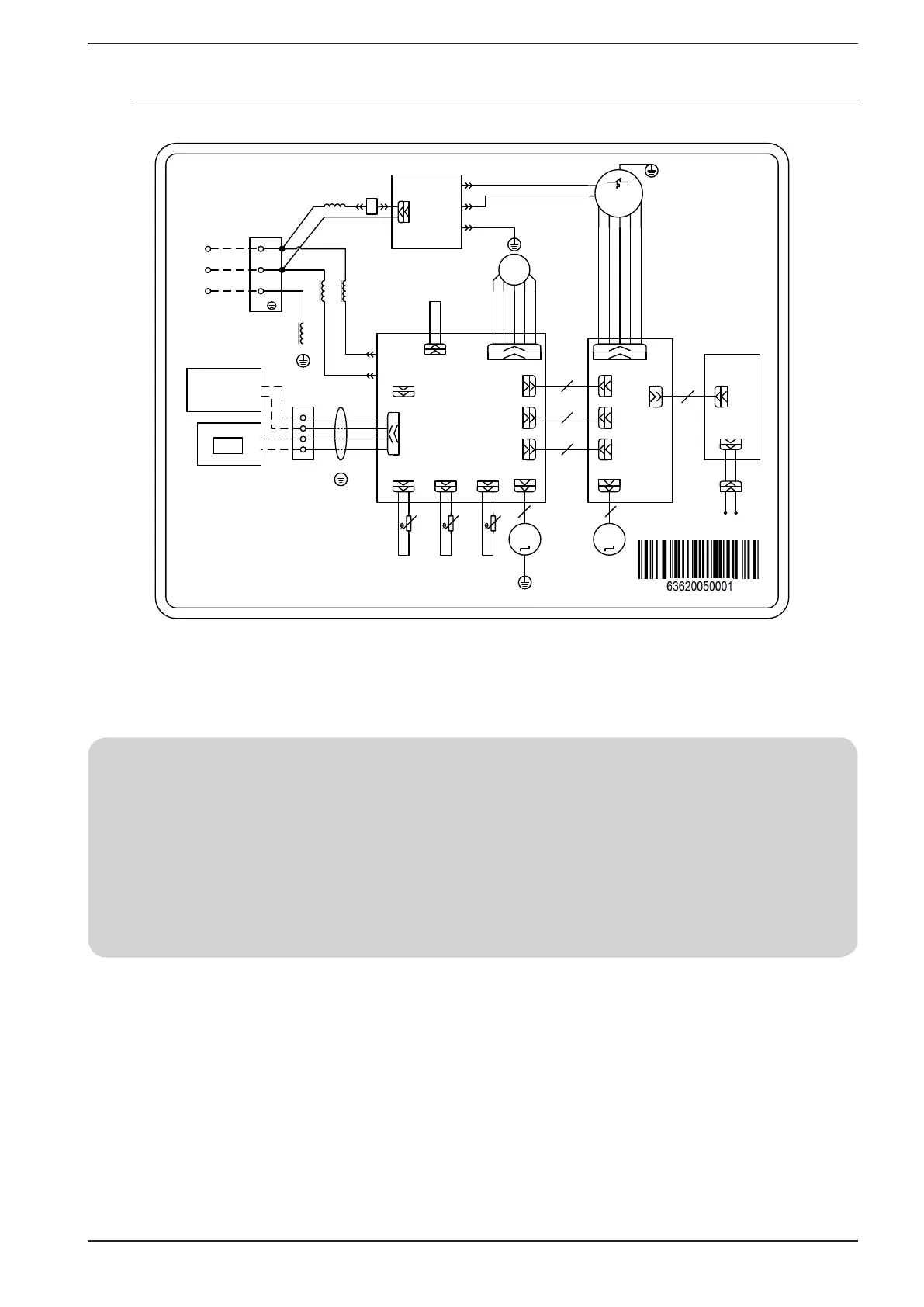

9.3. WIRING DIAGRAM MVA1000V - MVA1400V

POWER

N

L

AP1

MAI N BOARD

N

AC- L

PE

PE

NOUT

LOUT

PE1

CN1

AP2

FI LTER BOARD

~

M1

PE

CN2

CN12

D1

D2

H1

H2

I nt ercommuni cat i on

cor d f or I ndoor

and out door

Wi red cont r ol l er

AP3

LCD

JUMP

EKV

FB( FA)

FB f or el ect r oni c expansi on val ve

wi t h 5 cor es; FA f or el ect r oni c

expansi on val ve wi t h 6 cor es.

CN25

CN28

CN26

15K

RT1

20K

RT2

20K

RT4

ROOM

TUBE- O

TUBE- I

ROOM TEMP.

SENSOR

I NLET PI PE

TEMP. SENSOR

OUTLET PI PE

TEMP. SENSOR

M2

M3

CN22

5

AP4

CONNECTI ON

BOARD

CN22

5

CN11

CN21

CN17

CN21

CN17

CN11

4

6

5

RD

BK

BN

OG

RD

WH

RD

WH

YEGN

CN12

CN12

CN1

BN OG

XT1

XT2

AP5

DI SPLAY

BOARD

I NDOOR UI NT

4

YEGN

RD

BK

PE

RD

BK

BK

BK

WH

The wi r ed cont r ol l er i s

t he opt i onal accessor y.

CAP

CN35

GN

L1

L2

I nduct ance

XT3

BK

RD

1

X1

PE

XT2- H1 XT2- H2

BN OG

For the need of installation refer necessarily to the wiring diagram supplied with the unit. The circuit dia-

gram along with the manuals, must be carefully preserved and made available for future work on the unit.

NOTE IN CONNECTING THE WRC WIRE PANEL

The unit has a display on the machine from which it is possible to set all its functions, however it is also supplied with a WRC wire panel and

a WLRC infrared remote control.

In case you want to use the WRC flush panel to use the unit, you must perform the following procedure:

(1) Physically connect the wire panel to the indoor unit PCB (H1, H2 XT2 terminal board) as indicated in paragraph 9.2;

(2) The alarm message “CP” (control panel conflict) will appear on the display;

(3) While the unit is OFF, press the “Mode” and “Speed” keys simultaneously for 5 seconds to clear the “CP” alarm and enable normal ope-

ration (in this configuration the WRC panel will turn out to be the master compared to the display on the machine);

Loading...

Loading...