10

Ø Pipe thickness Tightening torque

1/4” ≥0,8 15 - 20

3/8” ≥0,8 30 - 40

1/2” ≥0,8 45 - 55

5/8” ≥0,8 60 - 65

7/8” ≥0,8

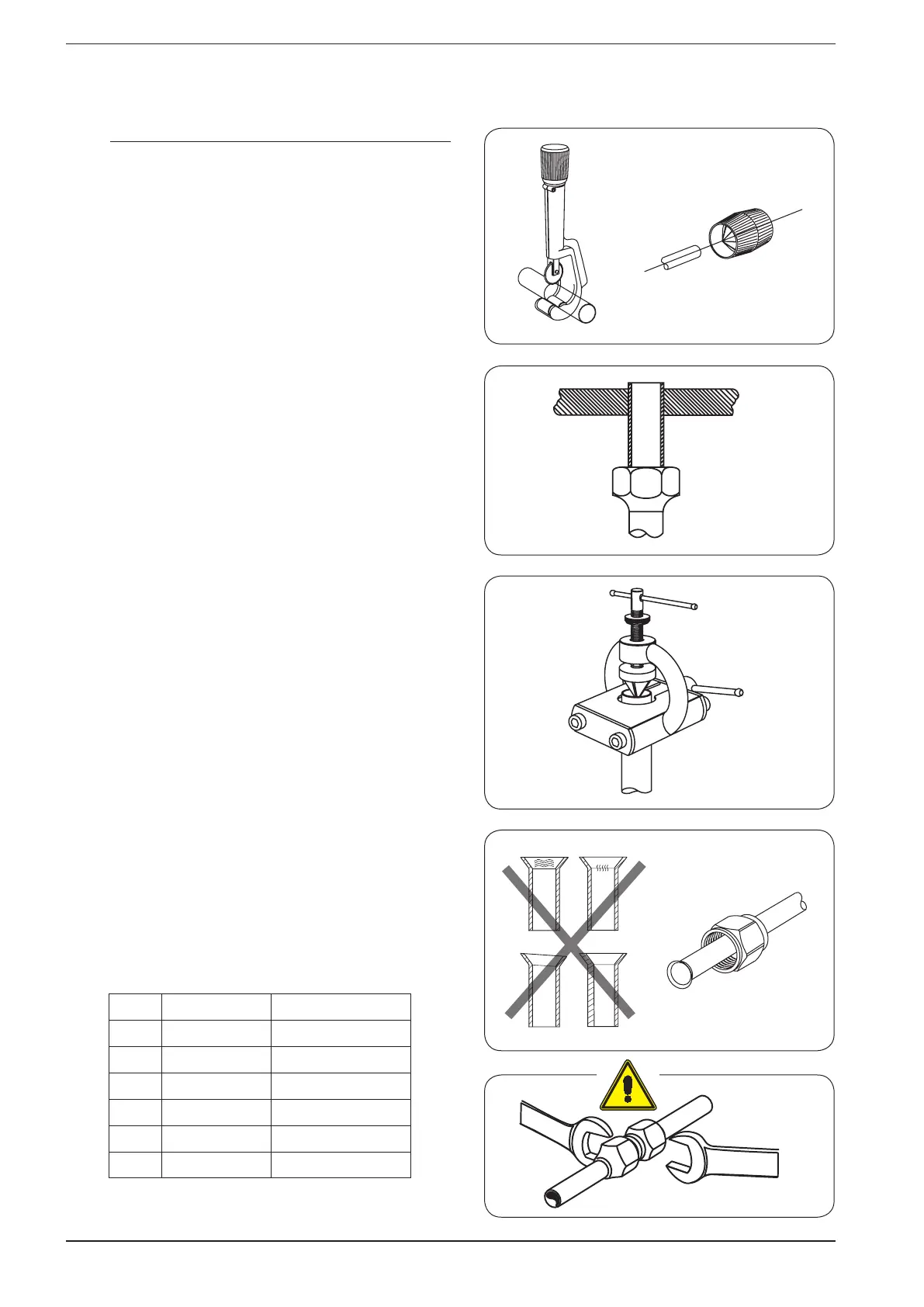

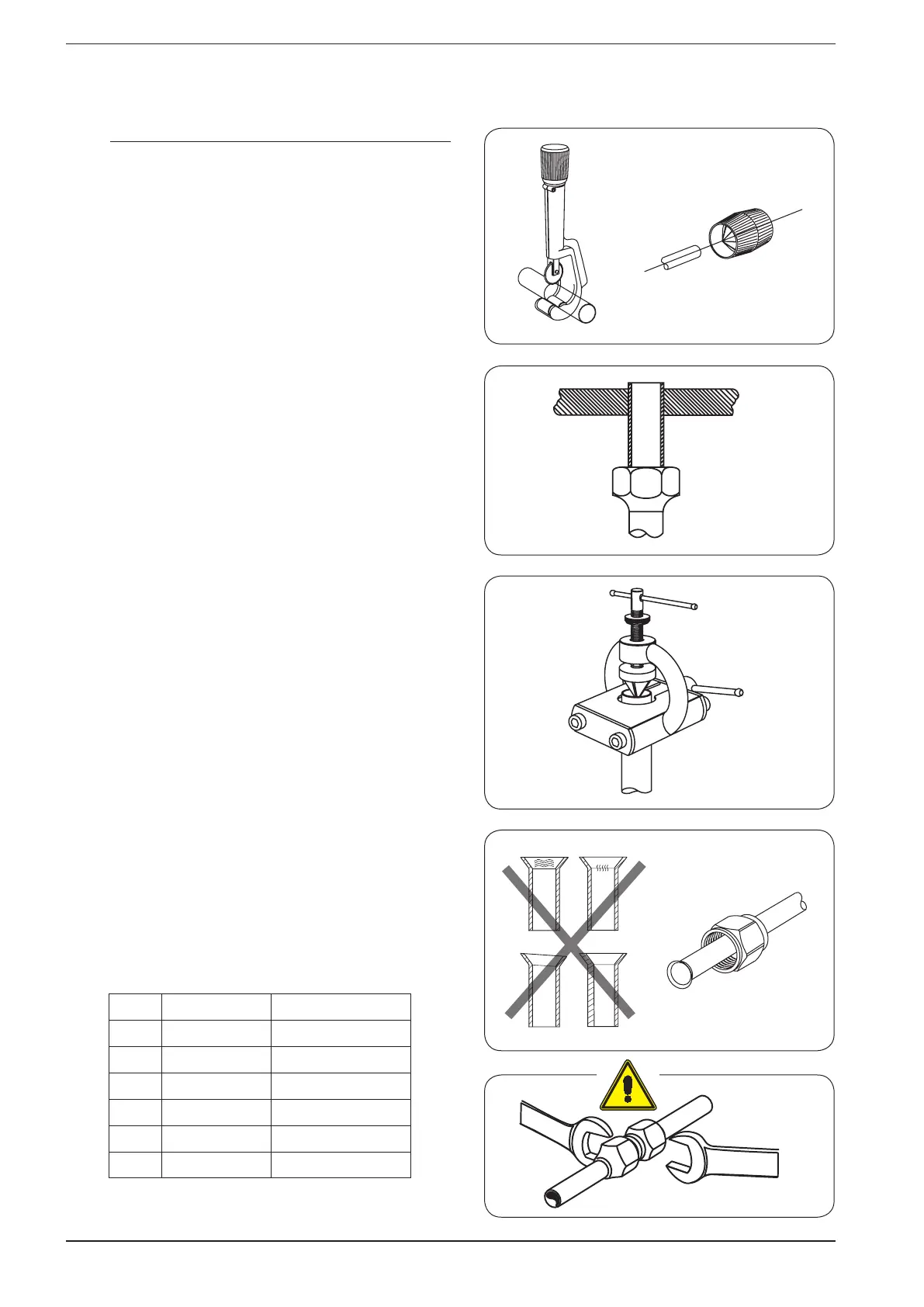

Fig. D

Fig. A

Fig. B

Fig. C

Fig. E

8.1. FITTING THE REFRIGERANT LINES

• Refrigerant R410A

• Use copper pipes for gas and liquid, as indicated in the relative

table (see the connection pipes table).

• Before assembling the insulated copper pipes on the refrigerant

lines, seal both ends of each pipe to protect the inside from dust

and humidity. The inside of the pipes must be perfectly clean and

free of any foreign bodies.

• Try to avoid bending the pipes. If you must bend them, the bend

radius should be greater than 100mm.

• The refrigerant lines in multi-split systems must meet strict limitations

related to the type of outdoor units used; for more information on

the limits and types of refrigerant connections refer to the technical

manuals or manual installation of outdoor units.

The multi-split systems can have systems connecting refrigerator, and joints,

which differ according to the type of product; However, once made va-

rious refrigerant lines (using accessories giungione refrigerator and gas di-

stribution provided by the system), the connection of indoor units to the

remaining lines of the system, follow the following points:

1. Shape the refrigerant lines from the indoor unit until they are at jun-

ctions provided on refrigerant lines of the system.

2. Prepare the lines on the side of the indoor units as follows:

• Accurately measure the inner and outer tube.

• Use a tube slightly longer than the measurement date.

• Cut the copper tube to length with the cutter and smooth the

ends using a pipe reamer (Fig. A);

• Insulate pipes and fit conical nuts before running the collar end of

the tubes (Fig. B);

• To perform the collars tapered at 45 ° using a conical tool for ed-

ging (Fig. C);

• Deburring the inside of tubes

• During the reaming, the pipe end must be higher of the reamer to

prevent the entry of dust in the pipe.

• Be sure the inside of the pipe is clean and free of residuals.

• Verify that the conical surface is in alignment with the tube, smo-

oth, free of fractures and with uniform thickness (Fig. D).

3. Check the height difference of the indoor and outdoor units to assess

the need of one or more siphons on refrigerant lines (for more details

refer to the section)

4. Before making the union of the lines with the unit, make sure that the

position is final.

5. Clean the surfaces of the joints so as to ensure perfect contact betwe-

en the clamping surfaces.

6. Lubricate with a thin layer of oil to the motor connections inside and

outside.

7. Connect and tighten the refrigerant lines at the indoor unit, use a key

and to avoid twisting the pipes (Fig. E).

8. Observe the tightening torque indicated in the table:

8. COOLING CONNECTIONS

Loading...

Loading...