50

DISPOSAL OF UNIT

The components of the TA series have been designed to run

continuously. The duration of some of the main components depends

on the maintenance they have received.

At the end of their life, the TA series units must be disposed of in

compliance with that foreseen by standards in force.

The unit must be dismantled by specialised personnel.

The main materials making up the units of the TA series are:

• galvanised steel sheets (panels, fans, condensation drip tray);

• aluminium or aluminium alloy sheets (coil louvers, grids, electric

motor casing);

• copper (coil pipes, electric motor windings);

• expanded polyurethane (insulation of sandwich panels).

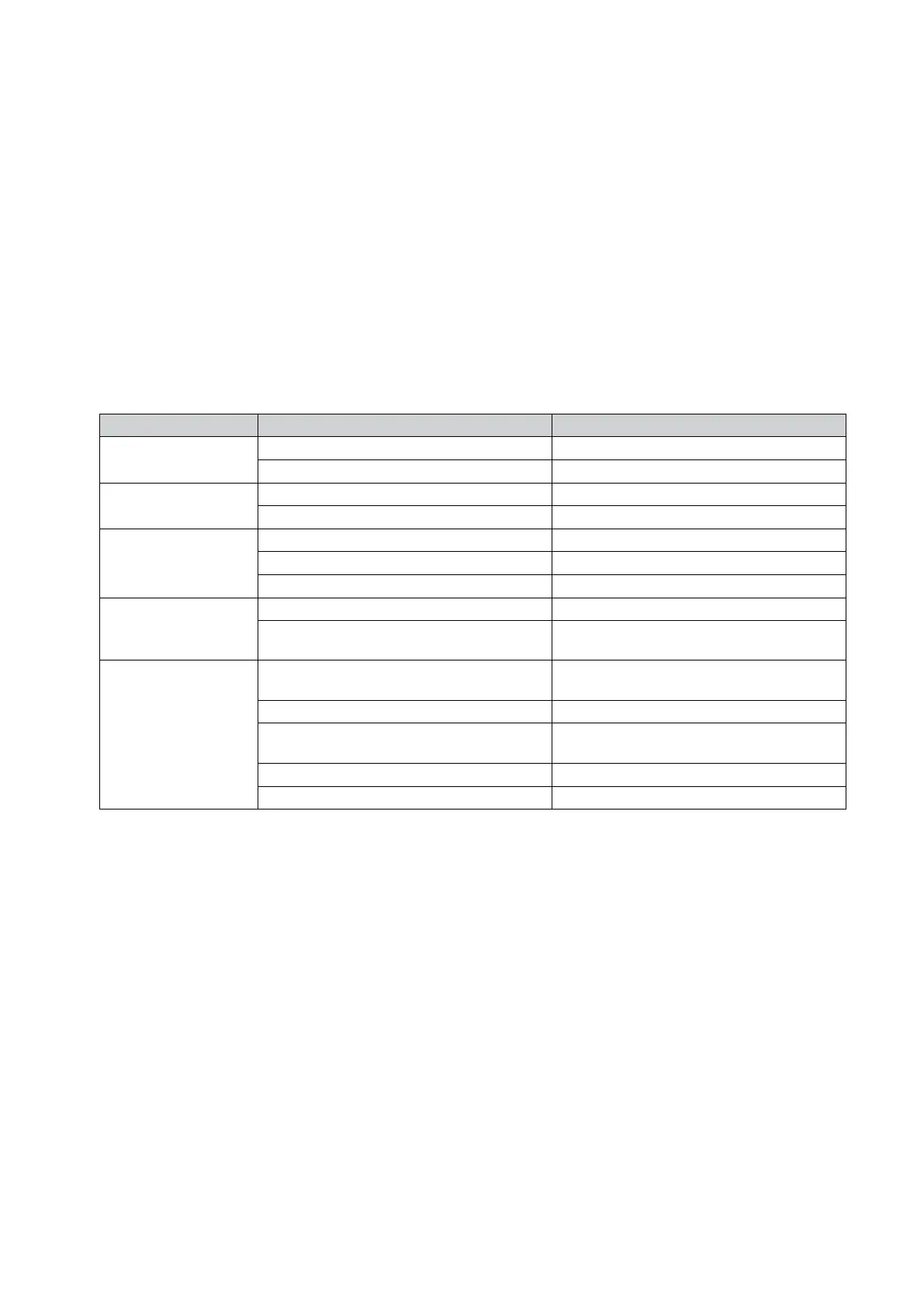

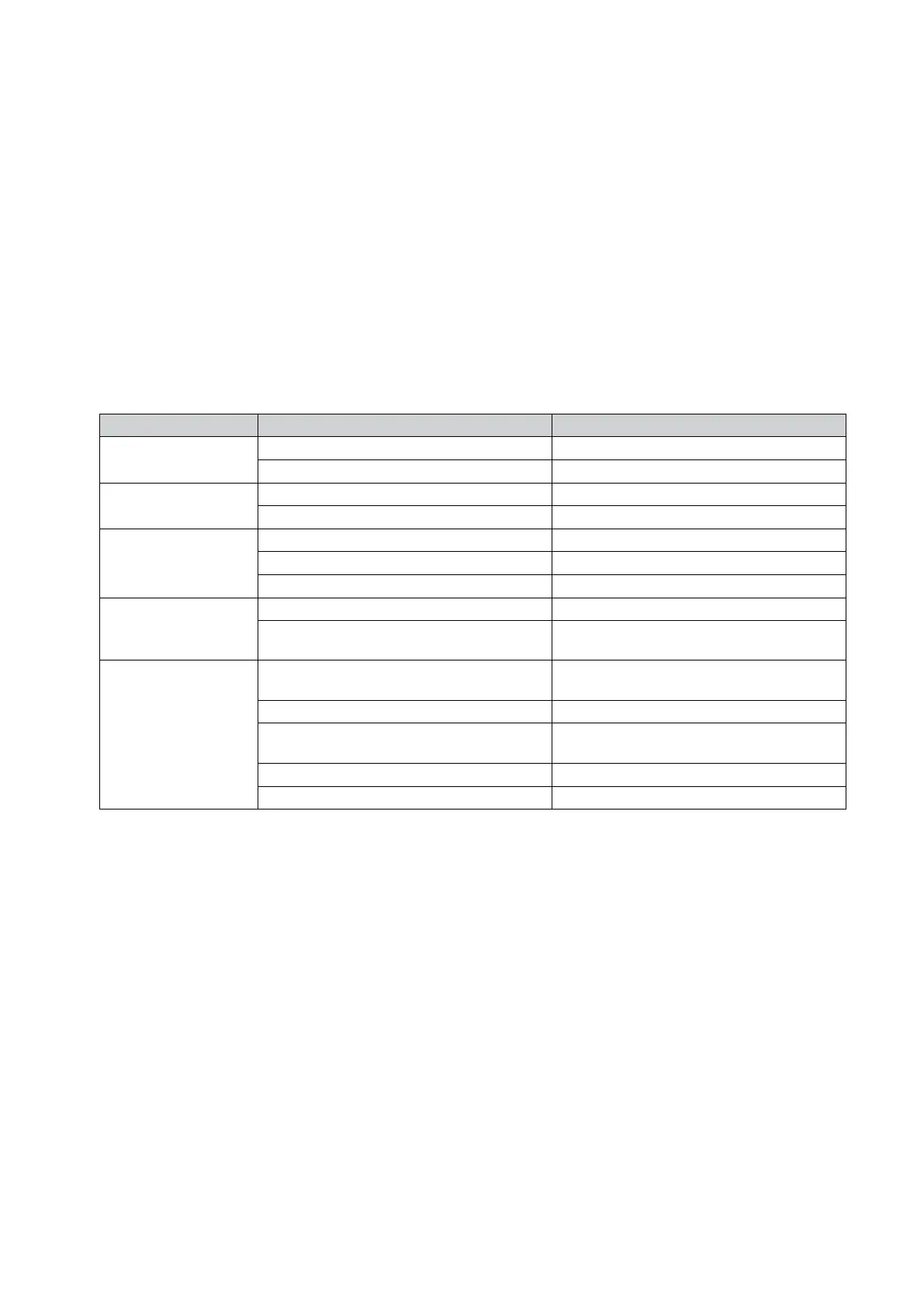

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

1. AIR FLOW RATE

INSUFFICIENT

1. Filters clogged - Clean the lters

2. Coils clogged - Clean the coils

3. NO AIR FLOW

1. Power disconnected - Check the presence of voltage

2. Electric motor burnt - Replace the electric motor

4. UNUSUAL NOISE

1. Excessive ow rate - Reduce ow rate

2. Fan bearings worn or faulty - Replace the bearings

3. Extraneous bodies on fan rotor - Clean the rotor

4. WATER CARRY OVER

1. Siphon clogged - Clean the siphon

2. No siphon or not installed properly

- Provide a properly installed siphon as indicated in

this manual

5. THE UNIT DOES NOT

REACH THE DESIRED

TEMPERATURES

1. Temperature of air entering coil outside of

foreseen limits

- Check water temperature

2. Air in water coils - Bleed the coils

3. Insucient water ow rate in water coils - Increase water ow rate

4. Insucient coil inlet water temperature - Check water temperature

5. Surface of coil pack dirty - Clean pack surface

Loading...

Loading...