49

UNIT MAINTENANCE

ATTENTION!

Wear proper personal protective equipment (PPE) to perform

maintenance.

ATTENTION!

Before accessing the unit for maintenance and/or

cleaning, make sure that it is not live, that it cannot be

powered without the operator knowing it and that the

heat exchange coils are not on.

ATTENTION!

Pay particular attention when working near the nned

coils as the louvers are particularly sharp.

ATTENTION!

When maintenance is nished, always close the unit

with its panels, xing them with screws.

The TA series units have been designed to require little maintenance

and to make every operation convenient. The following is simple

advice for correct maintenance of the unit.

In any event the maintenance program must be carried out by a

specialised technician.

ROUTINE MAINTENANCE

Routine maintenance consists in simple operations which should be

performed monthly as follows:

- check that the screws xing the fans to the panels are tight;

- check that the unit’s electric power cable has no alterations which

would jeopardise its insulation;

- check that the screws xing the conductors to the electric

opponents on the electric control board are tightened properly in or-

der to guarantee correct electric connection; the same must be done

for the earth connections.

FILTER MAINTENANCE (IF ANY)

Cleaning the lters is fundamental to keep the air quality in the room

at a high standard. The synthetic lters mounted on TA units can be

regenerated with a compressed air jet or washed with cold water. To

remove the lters, do as follows (see gure below):

• remove the inspection panels provided with knobs;

• pull the lters o;

• clean the lters;

• put all the components back on in inverse order.

MAINTENANCE OF FANS

It is essential to control and clean the fans to keep noise low in the

room where the unit is installed. Check yearly:

- check rotor cleanliness;

- check bearings noise;

MAINTENANCE OF COILS

Checking and cleaning the coils is fundamental to keep the air quality

and renewal in the room at a high standard.

Check yearly:

- check the nned pack cleanliness;

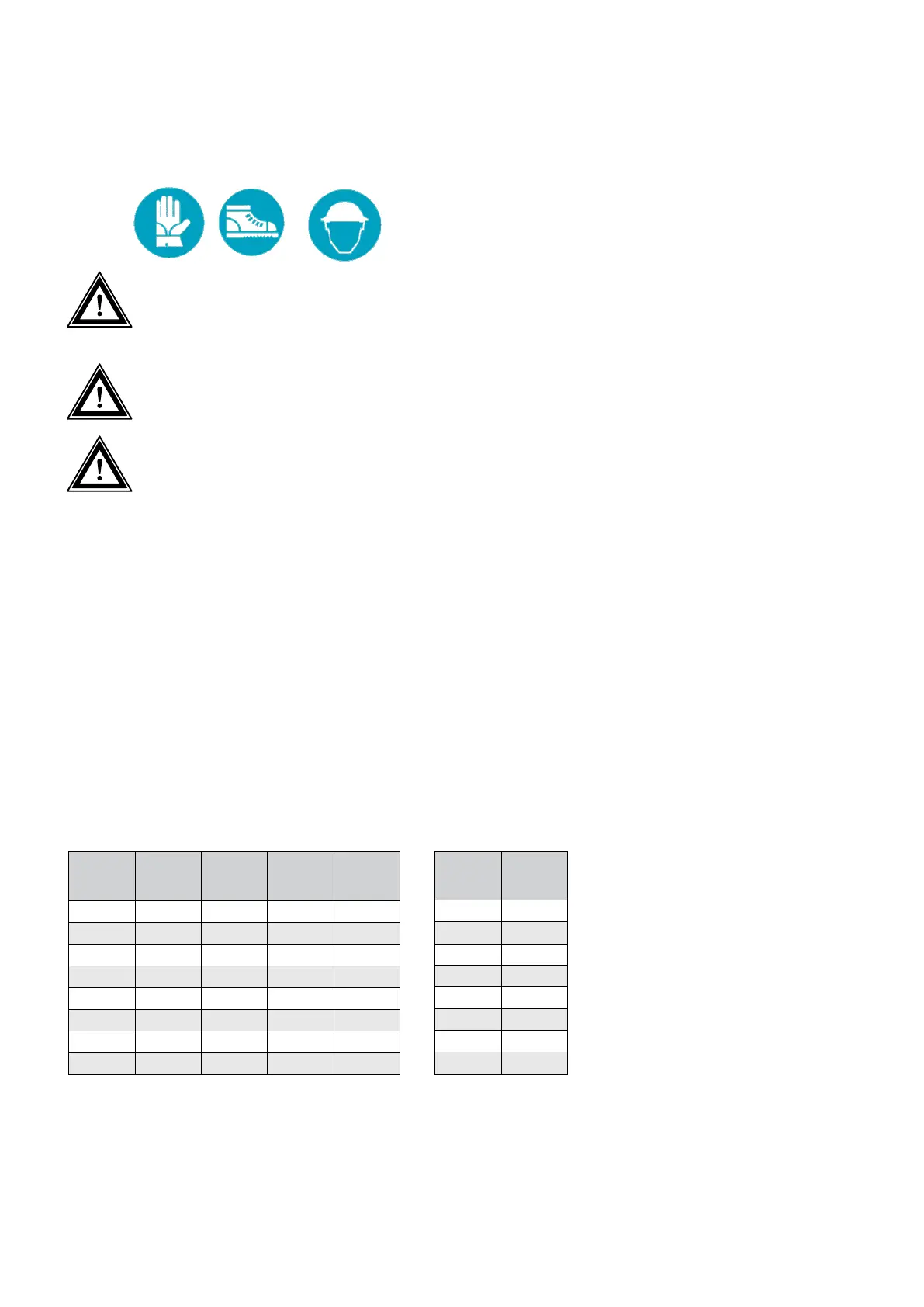

Dimensional table of filters used in the TA units

TA

FLAT

FILTER

665 x 265

FLAT

FILTER

1015 x 265

FLAT

FILTER

1440 x 355

FLAT

FILTER

2065 x 355

09 1

11 1

15 1

19 1

24 1

33 1

40 1

50 1

TA

BAG

FILTER

287 x 592

09 1

11 1

15 1

19 1

24 2

33 2

40 3

50 3

Loading...

Loading...