27

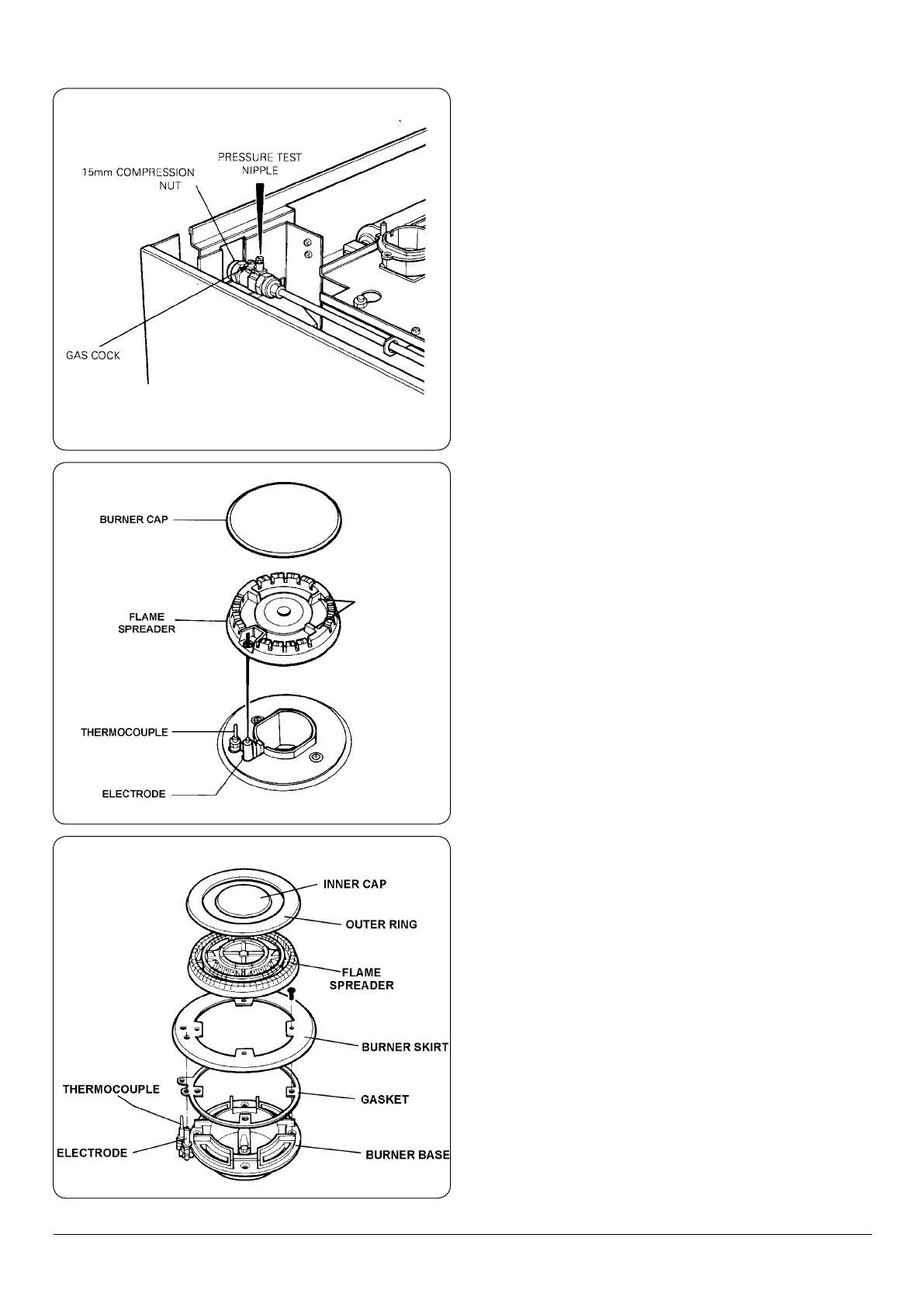

Connecting To Gas

The cooker must be installed by connection to rigid

pipework, which should not be less than 15 mm diameter.

Connection is made to the 15 mm compression tting

located just below the hotplate level on the rear left hand

side of the cooker.

1. Mark o approximate position on wall for gas supply to

cooker (See Specication).

2. Isolate the gas supply and connect pipework as required

up to the position marked.

3. Check for gas tightness after connecting the gas supply.

4. Make nal gas connection to the cooker (15 mm

compression) into the combined gas cock/pressure test

tting (See Fig. 11.6).

5. Check for gas tightness after connecting the gas supply.

Pressure Testing

The pressure test point is situated at the rear left hand side of

the appliance just below hotplate level. (Fig. 11.6).

1. Remove screw from pressure test nipple. Fit the pressure

gauge onto the pressure test nipple.

2. Turn the gas cock to the ON position.

3. Place one of the burner heads and burner cap into

position on the burner body. Push in and turn the

appropriate control knob anti-clockwise to full-on

position, and light the burner with a match.

4. For Natural Gas appliance, the pressure should be

nominal 20mbar (8 inches water gauge).

5. For LPG appliance (propane) the pressure should be

nominal 37mbar (14.8 inches water gauge).

6. Turn o the tap, turn o gas cock, disconnect the

pressure gauge and ret pressure test screw to pressure

test nipple.

7. Turn the gas cock back to the ON position.

8. Check for gas tightness.

Fig. 11.6

DESN 516858

DESN 513513

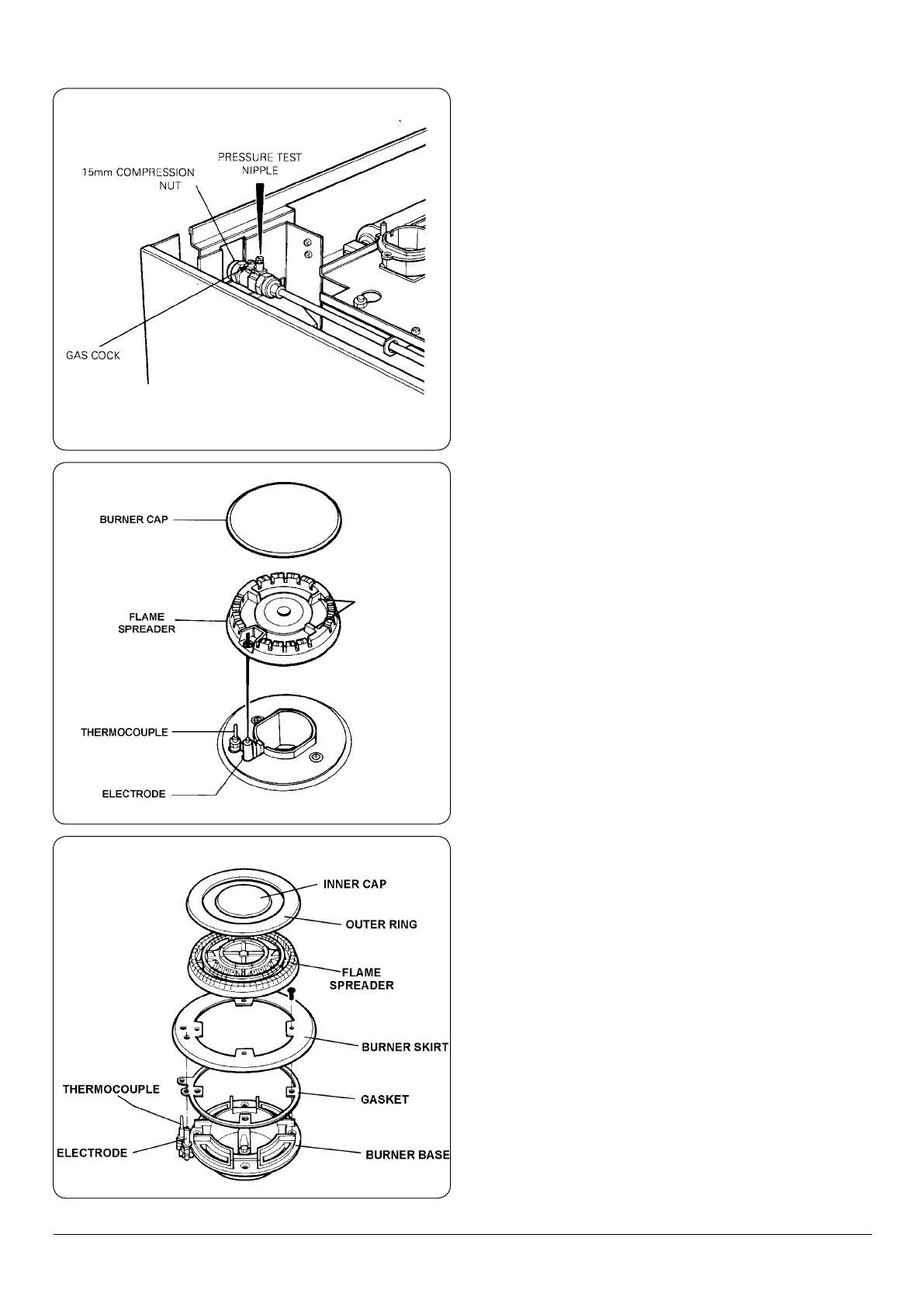

Fig. 11.7

BURNER CAP

RETAINING

LUGS

Fig. 11.8

DESN 513898

Loading...

Loading...