223

Theory of Operation

Autosampler Main Board (ASM)

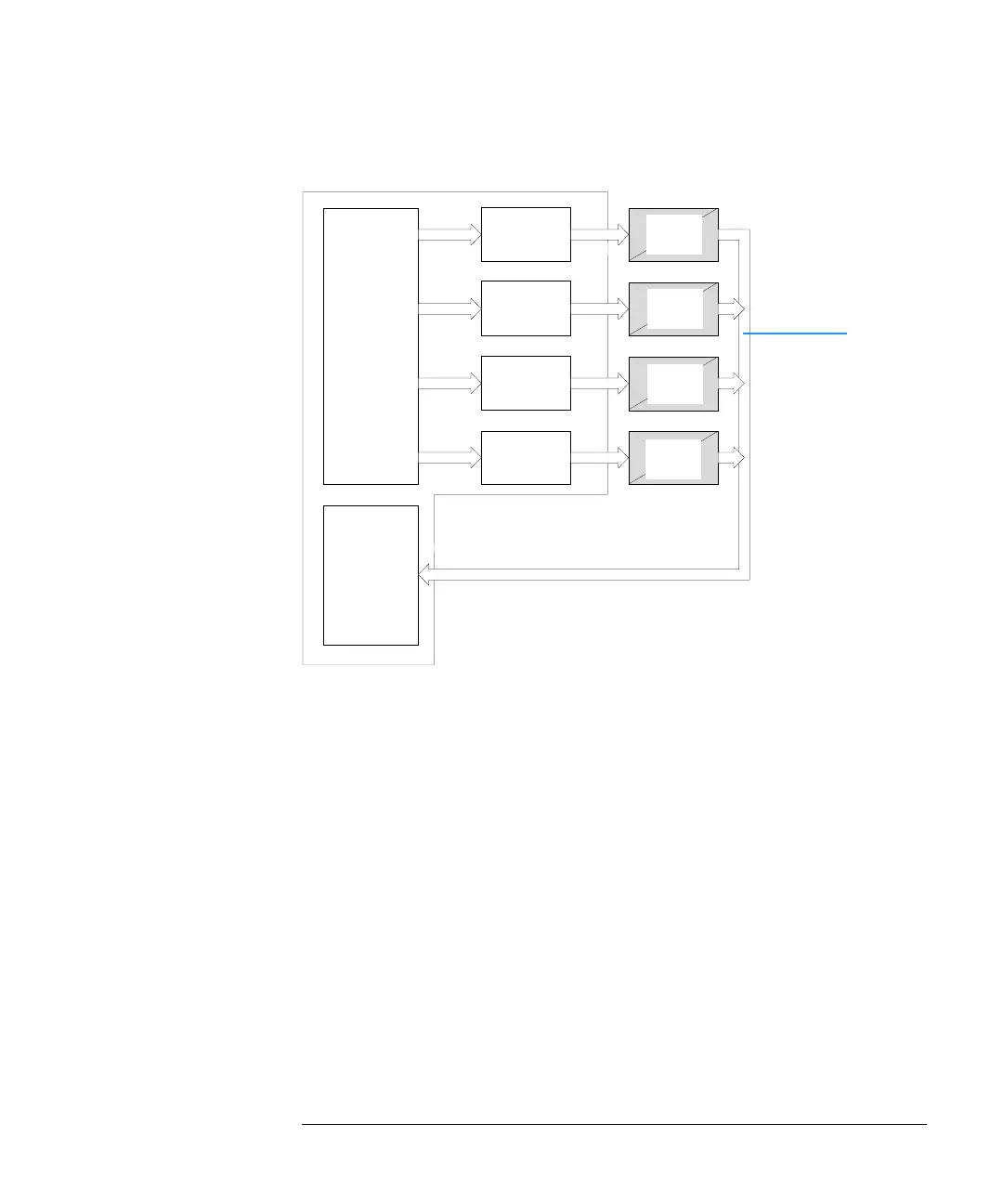

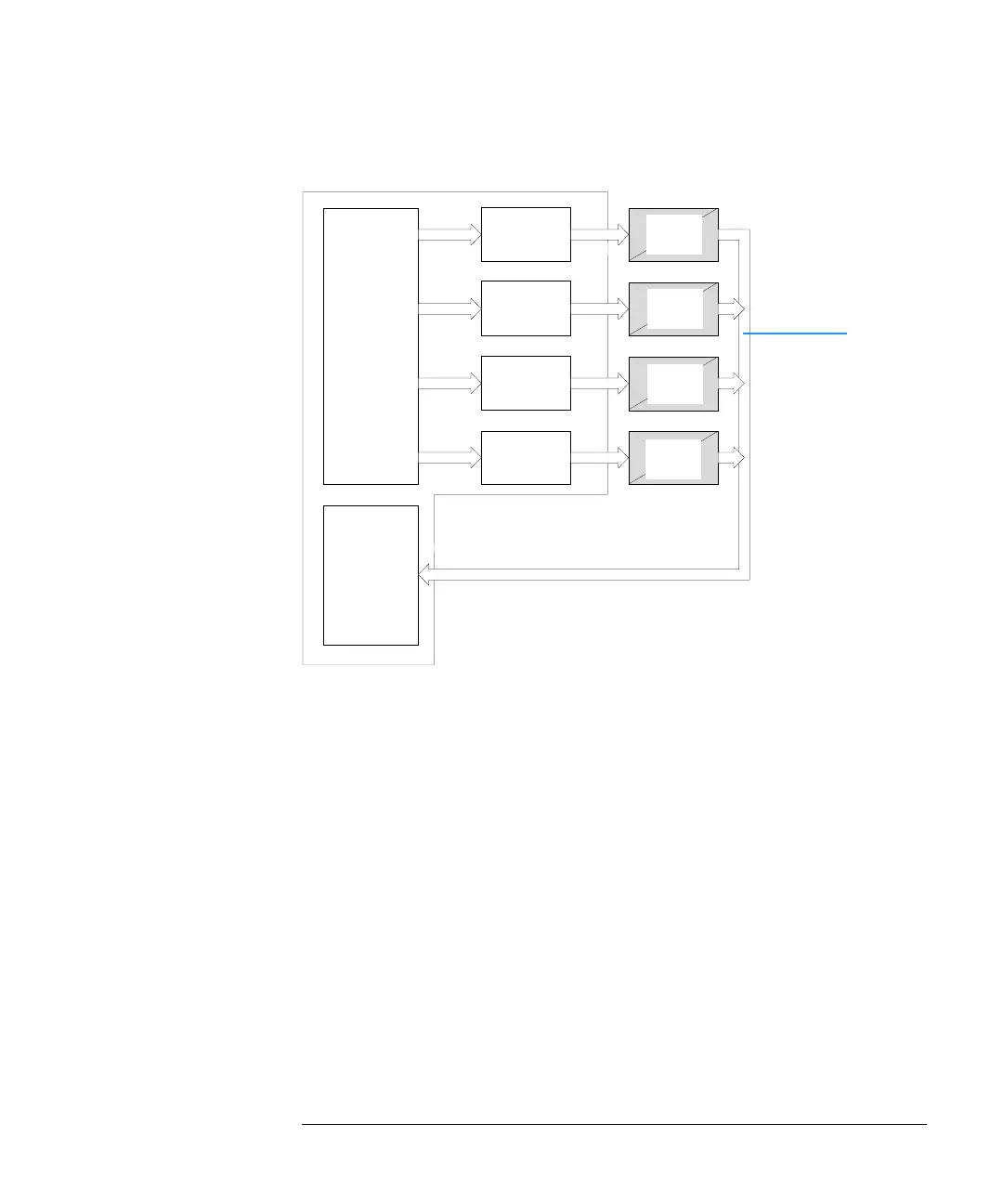

Figure 38 Transport unit control

Sampling Unit Control

Needle arm, metering device and valve motors are driven by controlled

pulse-width modulation in the same way as the SGS L6506 (see “Transport

Unit Control” on page 221). The motors require fast speed but do not

require precise position control. Therefore, a closed loop servo system is

not required. Commutation is done in FPGA logic. The needle arm,

metering device and valve motors use SGS L6203 output drivers to deliver

the higher currents required for fast movement or high torque.

The movement sensing of the valve motor is done by two microswitches.

Two reflection light sensors are used to detect the end positions of the

needle arm. One photo sensor is required to detect the home position of

the metering device. Two hall sensors detect correct closure of the door

(needle arm movement is interrupted if the door is open). All the sensors

are mounted on one flex board. The flex board and motors are connected

to the sampling unit distribution board (SUD). The SUD board is

connected to the autosampler main board (ASM) via a flat-band cable (64

pin).

FPGA

Theta Drive

Gripper Drive

X-Axis Drive

Z-Axis Drive

ASIC

Motor

Encoder

Motor

Encoder

Motor

Encoder

Motor

Encoder

Via transport

unit flex board

Reflection sensors on transport unit flex board:

Tray decoding (6), gripper decoding (1), initialization sensors

(3).

Loading...

Loading...