AHT Cooling Systems GmbH

22.05.2018 14:09 Page 38

347163_0917_BA_ AC-COOLER_V8_06.09.2017_U_enUS_CD.docx

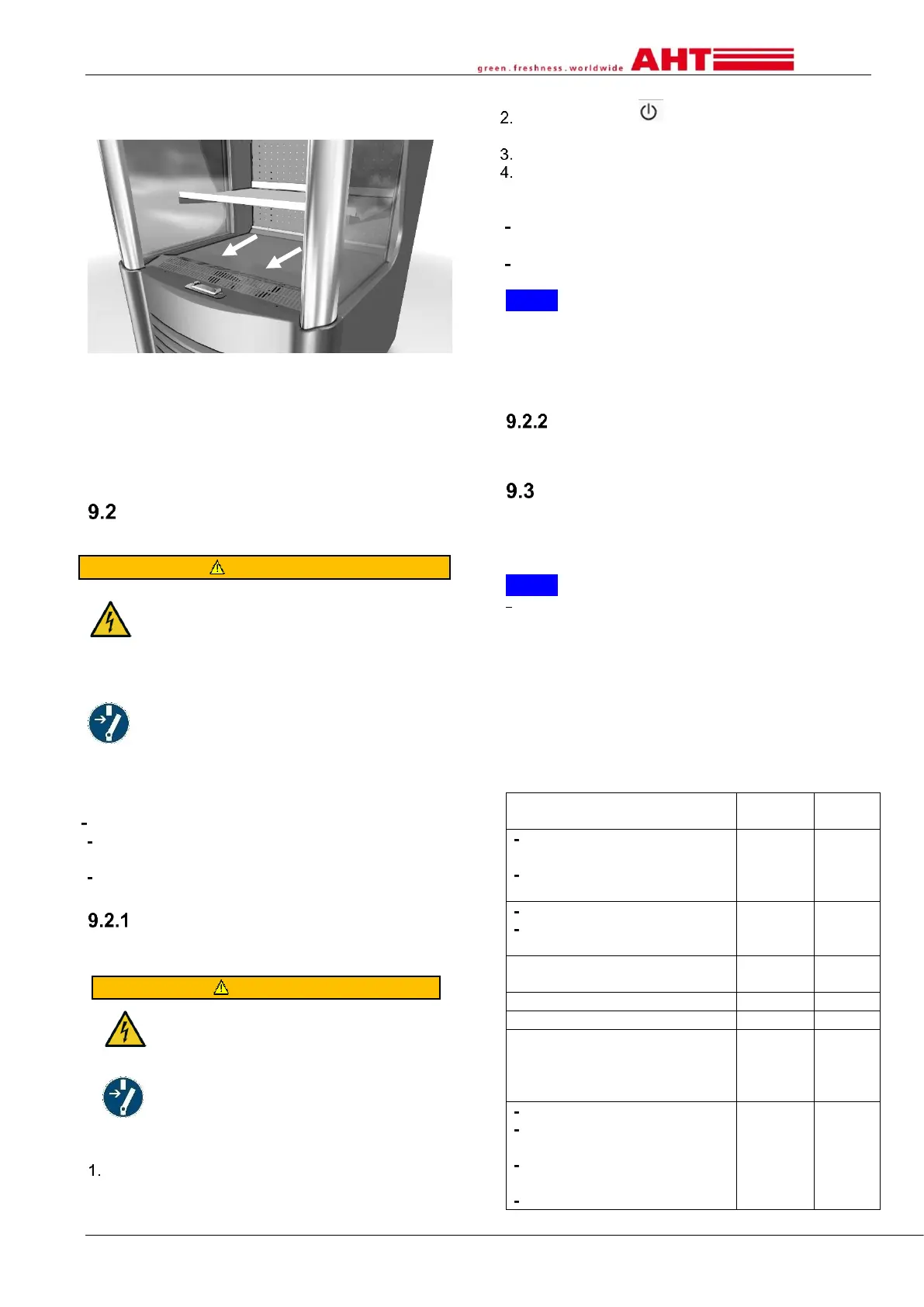

►Loading is only permitted up to the limit of the

return air intake grille (see → Fig. 5).

Fig. 5: Return air intake grille

►Do not load beyond the end of the shelf.

►Do not block the night blind by loading with

goods. The night blind must be able to close

completely (see → Chapter 4.2.4).

Decommissioning and

recommissioning

Work on the electrical system.

Contact with live parts may cause electric

shock.

►Work on the electrical system may only

be performed by qualified staff.

►Observe the electrical safety rules

before starting work.

1. Disconnect the device.

2. Secure the device against restarting.

Reasons for decommissioning by qualified staff

Maintenance, service, repair (see → Chapter 10.2)

Main cleaning (see → Chapter 10.1.2)

by operating staff

Damage to the device

Decommissioning

The decommissioning must only be performed by

trained operating staff.

Decommissioning of the device.

Contact with live parts may cause

electric shock.

►Only previously trained staff may

turn off the device.

►Switch off the device and secure it

against restarting.

Steps for decommissioning for operating staff:

Move the goods to another device with the same

product temperature class.

Disconnect the device:

Press button [5] on the operating element

(see → Chapter 4.2).

If fitted, switch off the main switch.

Disconnect the plug.

Prolonged decommissioning:

Perform steps for decommissioning (see →

above).

Carry out the basic cleaning (see → Chapter

10.1.1).

NOTE

• Material and property damage in the case of

prolonged decommissioning.

►Do not expose the device to heat radiation.

►Do not place anything on the device.

►Store the device only in its operating position.

Recommissioning

See commissioning → Chapter 8.

Faults in operation

Display operating element: (Fault code and

buzzer): see → Chapter 4.2.

NOTE

• Material and property damage with alarm display

by the fault code/buzzer.

►Move the goods to another device with the same

product temperature class.

►Contact the maintenance service immediately

(see → Chapter 10.4).

10 Maintenance

Monitoring tasks by operating staff:

Check that the device is in

perfect condition

Check for foreign objects in

the goods compartment

Damaged glass element

Breakage of stored glass

containers

Checking for contamination

Development of puddles in front

of/underneath the device

(defrosted water, fluids from

damaged packaging)

Contamination of the device

Food waste and packaging

waste

Visual inspection of the area

under the air intake grilles

Floor (around the device)

Loading...

Loading...