5-2 EB AT-RP-4GU EN

Mounting and assembly

Before mounting the actuator over the valve, make sure the

following conditions are met:

− The actuator is not damaged.

− The type designation, material and temperature range of

the actuator match the ambient conditions (temperatures

etc.). Refer to ‘Markings on the device‘ in section 2 for

nameplate details.

− Check compatibility of the valve stem to the actuator bore.

The length, size and configurations must match.

− Check compatibility of actuator, valve and bracket bolting

pattern.

− Before fitting the actuator over the valve, make sure that

the actuator and the valve are correctly oriented, with re-

ference to the rotation direction and fail action required.

− Make sure that the tubing, fittings and seals connected to

the actuator are cleaned to prevent foreign matter/objects

entering into the actuator’s chambers.

− When fitting accessories over the actuators, assemble

them in such a way that the emergency controls are easily

accessible for emergency manual operation.

− Check that the exhaust ports are not obstructed.

− Remove the plugs from the actuator air connections during

installation and operation, protect and close the air

connections which may not being used immediately.

− Make sure that the operating pressure media composition

used for the actuator operation meets the operating condi-

tions given in this manual and corresponds to what the ac-

tuator was manufactured for. Refer to section 3 ‘Design

and principles‘.

− It is the user responsibility to ensure that actuator and con-

trol components must be protected from electrical spikes,

surge and lightning strikes as well as all magnetic fields.

− Prevent any dangerous and/or corrosive substances in the

working environment enter into the internal chambers by

using adequate filters and/or solenoid valves and/or any

other appropriate system.

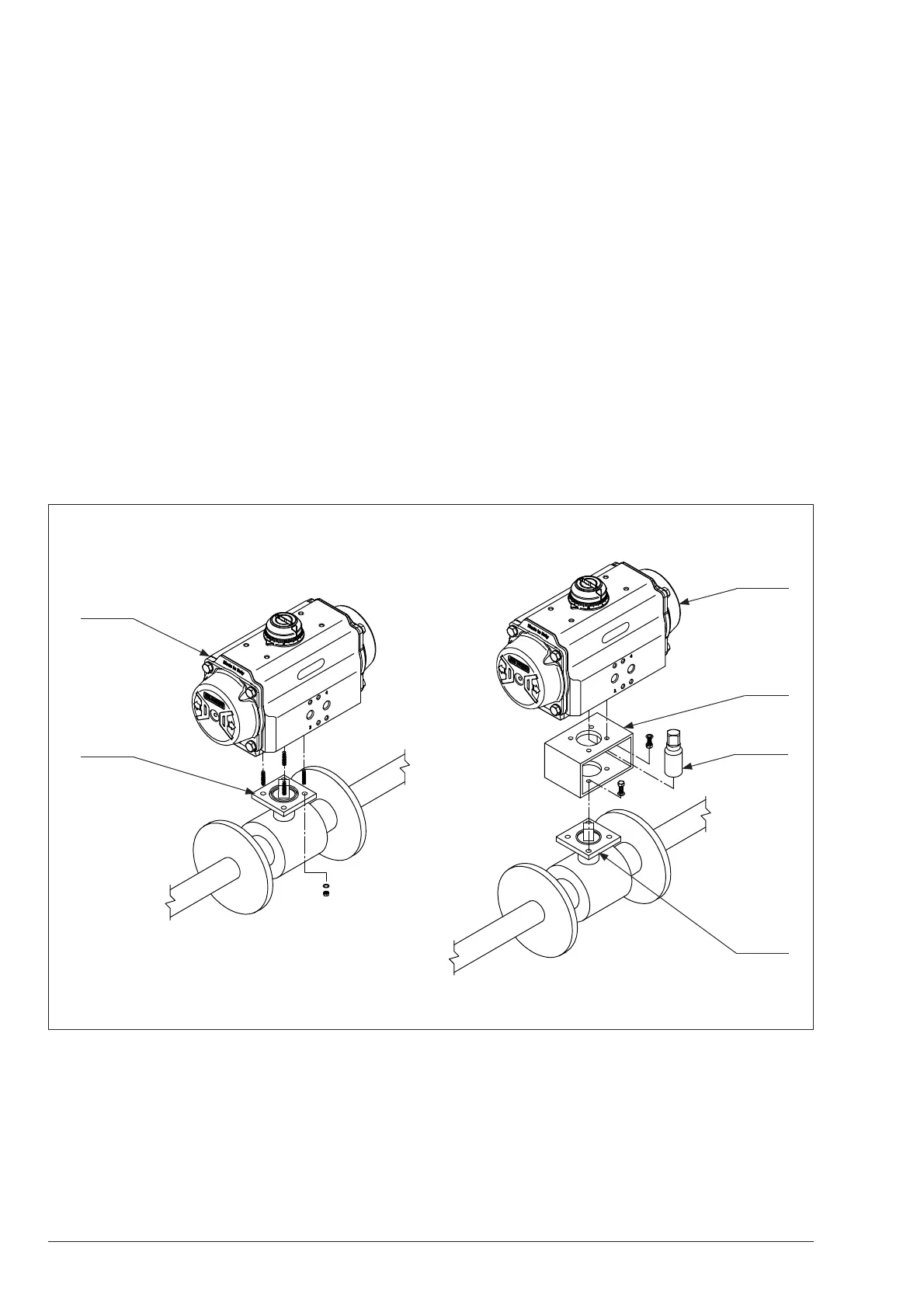

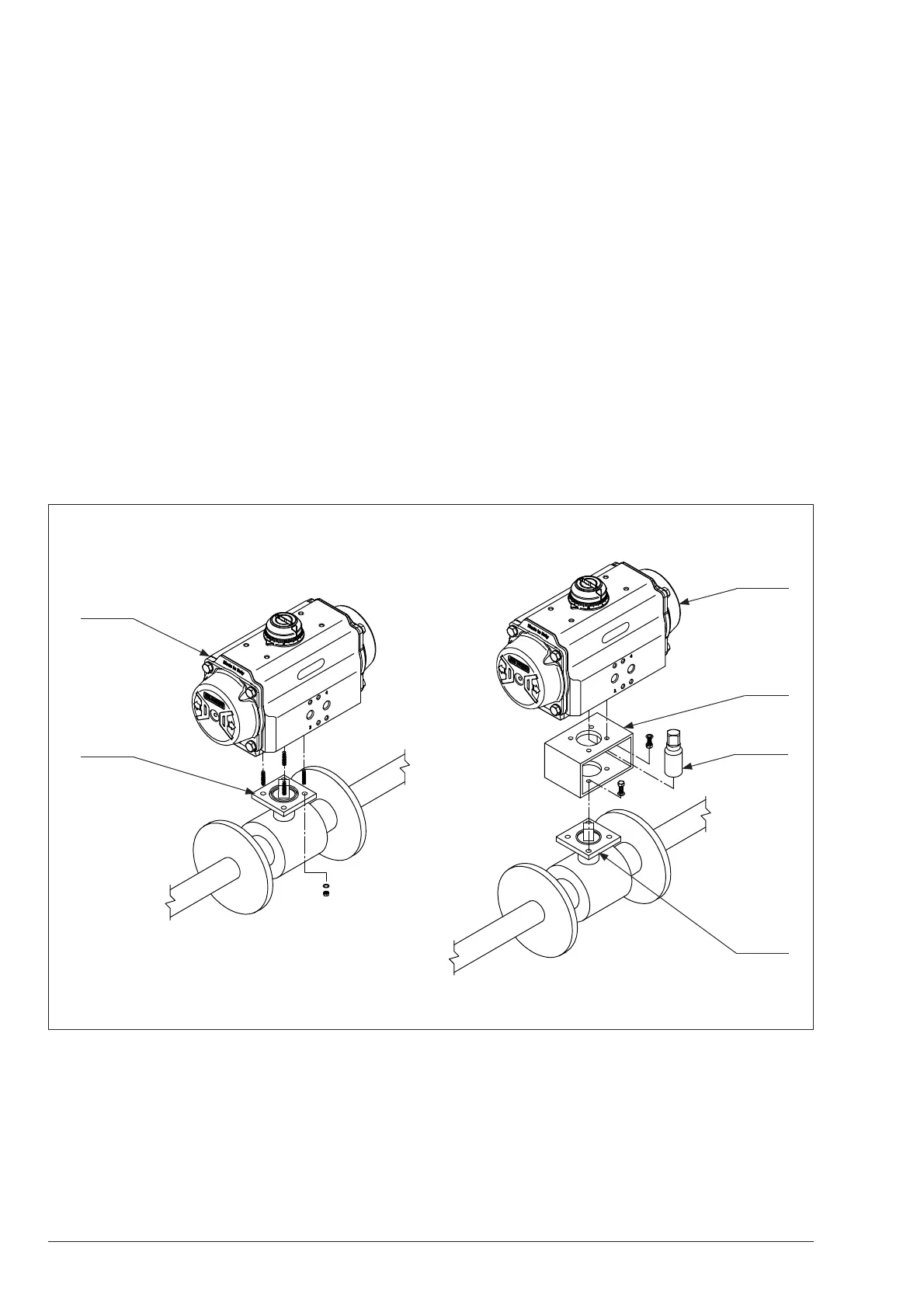

Fig. 5-2

Coupling

Bracket

Valve

interface

Actuator

Valve

interface

Actuator

DIRECT MOUNTING MOUNTING WITH BRACKET

Refer to Fig. 5-2 and proceed as follows to mount the actua-

tor over the valve:

1.

Disconnect any electrical/pneumatic/hydraulic power

supply.

2. Lay out the necessary material and tools to have them rea-

dy during mounting.

3. The actuator is supplied in the fail position (for single-ac-

ting), so drive the valve in the right position as per the ac-

tuator fail position.

4.

Clean the actuator‘s bore and the bottom flange.

5.

Clean the valve and the actuator interface to remove com-

pletely any lubricant.

Loading...

Loading...