9-6 EB AT-RP-4GU EN

Service

Double acting actuators

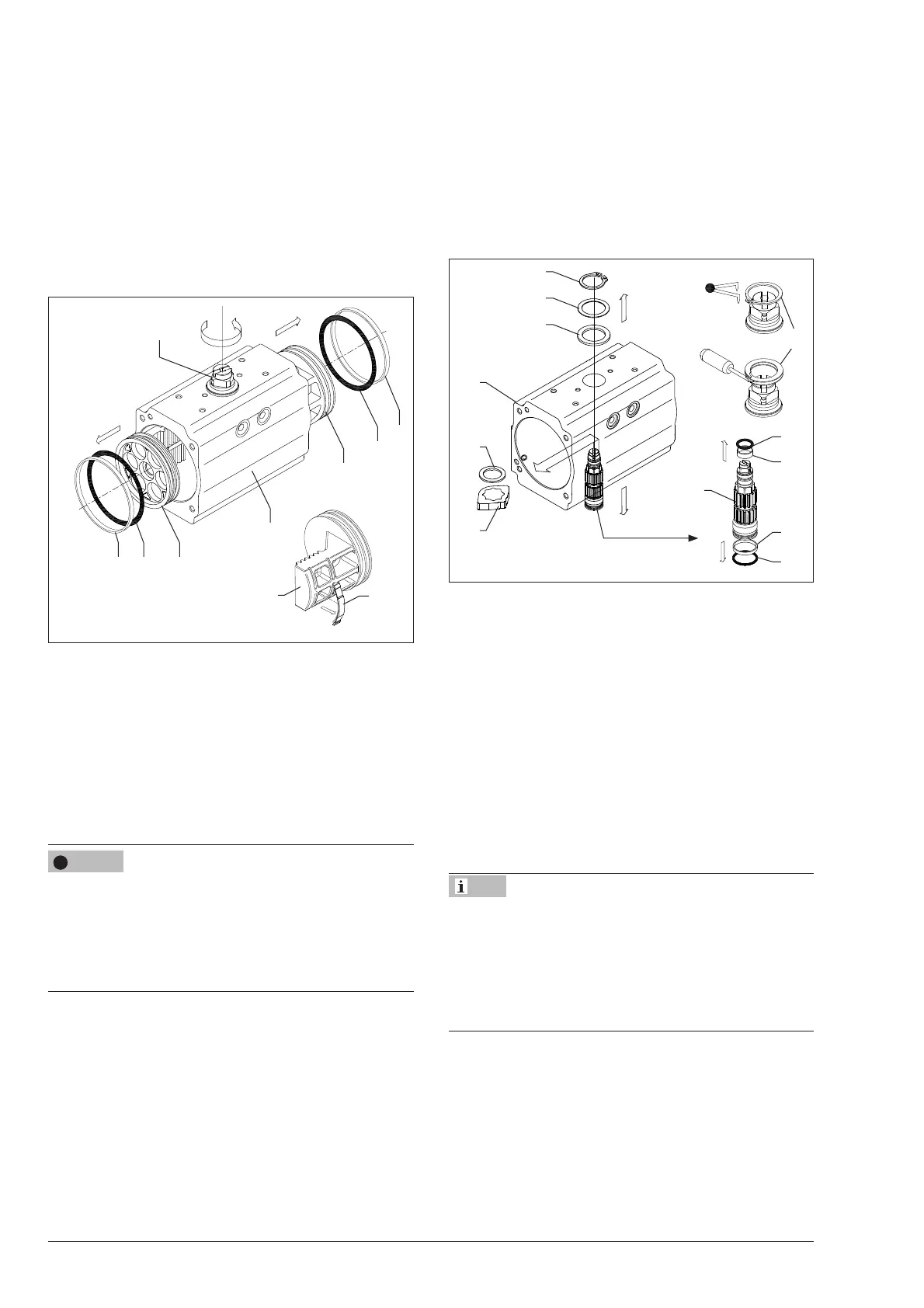

− Unscrew completely the end cap bolts (13) as per the se-

quence shown in the Fig. 9-5.

− Remove the end caps (30).

− Remove the o-rings (14). (Fig. 9-6)

9.3.4 Pistons disassembly

Refer to Fig. 9-1 and Fig. 9-7.

Fig. 9-7

60/60.1

16 40

40

16

15

15

50

40 05

− Holding the body (50) with a bench vice or a similar de-

vice, rotate the drive shaft (60/60.1) until the pistons (40)

are disengaged.

− Remove o-rings (16), the piston backs (05) and the piston

head bearings (15).

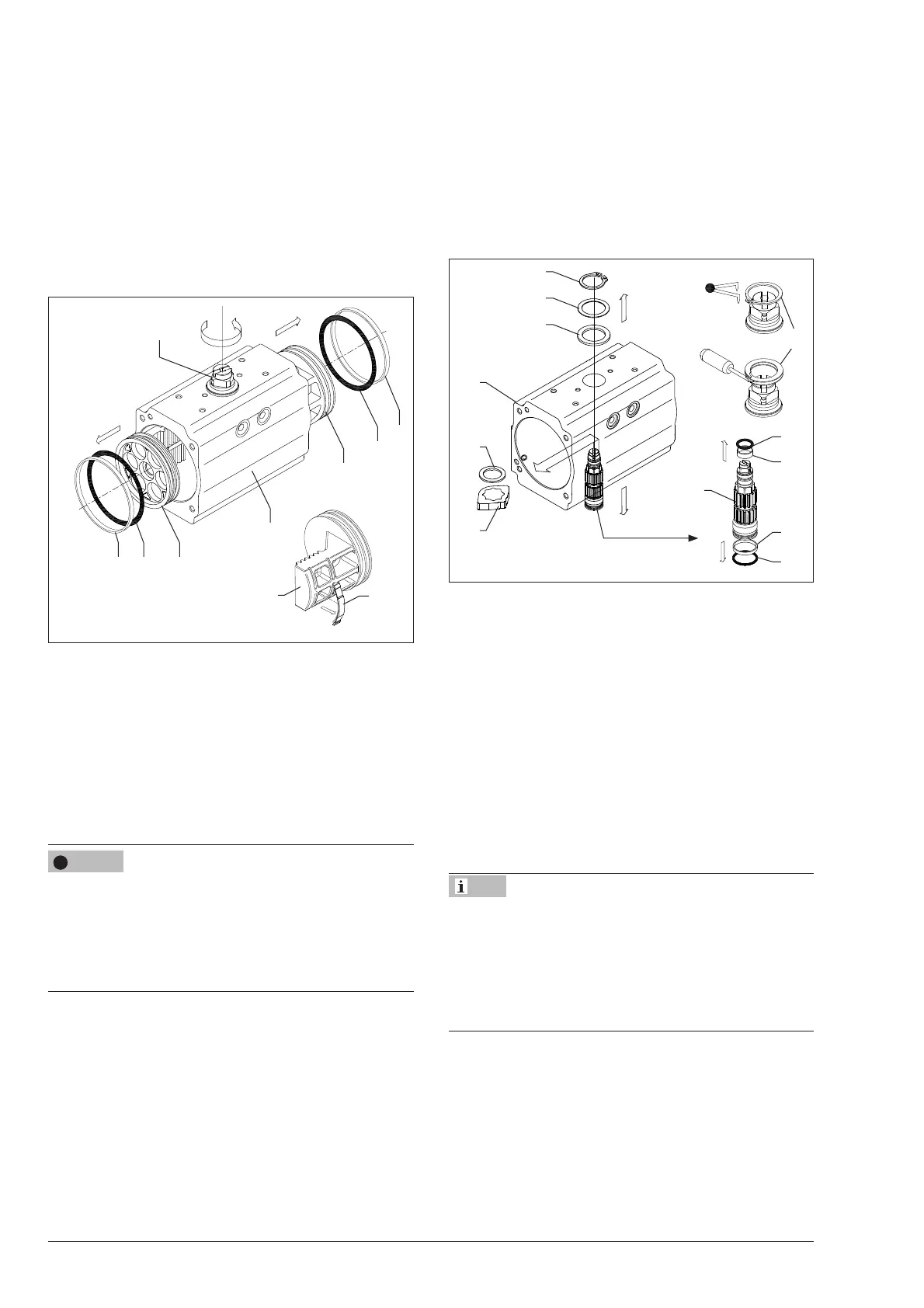

9.3.5 Drive shaft disassembly

Refer to Fig. 9-1 and Fig 9-8.

Risk of spring clip damage due to incorrect disassembly.

During disassembly the spring clip (18) can get overstressed if

not carefully handled.

Î Use proper tools to disassemble the spring clip.

Î In case of spiral spring clip (18) refer to the disassembly

and reassembly instructions available from AIR TORQUE.

− Remove the spring clip (18) by means of snap-ring pliers

or a screwdriver for spiral rings.

− Remove the thrust washer (10) and the external thrust bea-

ring (08).

− Apply downward force to the top of the drive shaft

(60/60.1), until it is partially out of the bottom of the body

and remove the internal thrust bearing (08) and the oc-

ti-cam (01).

− Push the drive shaft (60) completely out of the body.

If needed, gently tap the top of the drive shaft (60) with a

plastic hammer.

− Remove the drive shaft top bearing (06) and bottom bea-

ring (07).

− Remove the drive shaft top o-ring (21) and bottom o-ring

(20).

Fig. 9-8

06

07

21

20

60

60.1

50

18

08

01

10

08

18

9.4 Service operations

Inspect and clean every single component.

Inspect, clean and replace bolts and nuts, if needed.

Discard and replace the damaged soft components available

in the spare parts kit.

Î Refer to the spare parts kit data sheet [RP10600E] and to

the Rubber products storage instructions [T 3.3.3.1 EN].

Clean and lubricate every o-ring housing.

Î Refer to the section 15.3 ‘Lubricants‘.

9.5 Reassembly

in case of special actuators functions / features (R&P) refer to

the corresponding instructions:

- Fail mid “FM“ → EB AT-RP-4GU-FM,

- 180° SR → EB AT-RP-4GU-180SR,

- HCD → EB AT-RP-4GU-HCD,

- 3P / 3PD → EB AT-RP-4GU-3P.

Proceed as follows for the standard assembly of 4

th

GU series

actuators (AS-ST code indicated in the nameplate).

Î Refer to the TYAS technical data sheet in case of actuators

with different function/rotation.

Î Refer to the Catalogue 4THGU-E for actuators different as-

sembly codes.

NOTICE

!

Note

Loading...

Loading...