EB AT-RP-4GU EN 9-5

Service

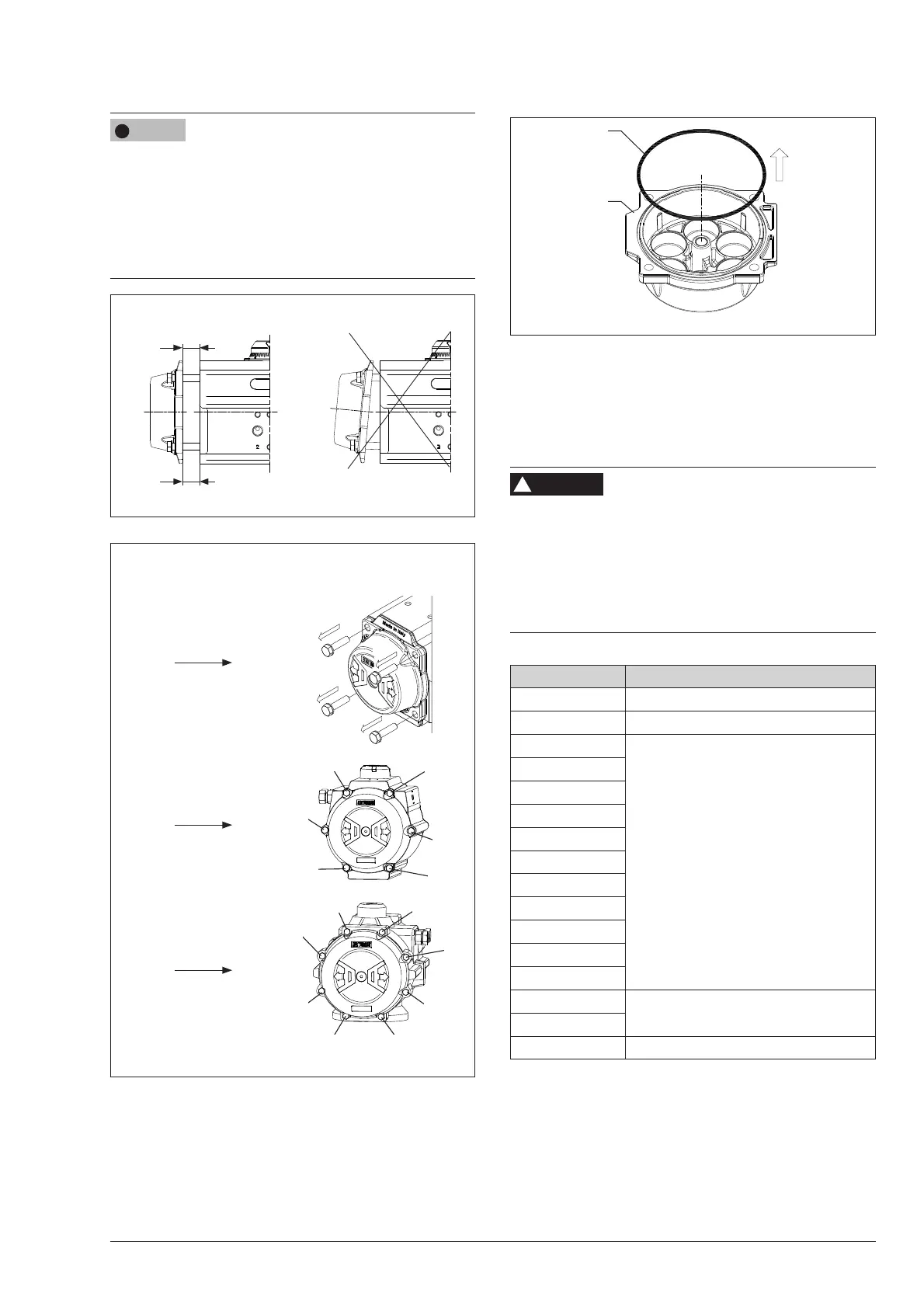

Risk of components damage due to incorrect disassembly.

During disassembly the end caps can be damaged due to un-

even force generated by compressed springs.

Î Remove the end caps as shown in Fig. 9-4 keeping a

constant distance (A = B) between the actuator body and

the end cap interface.

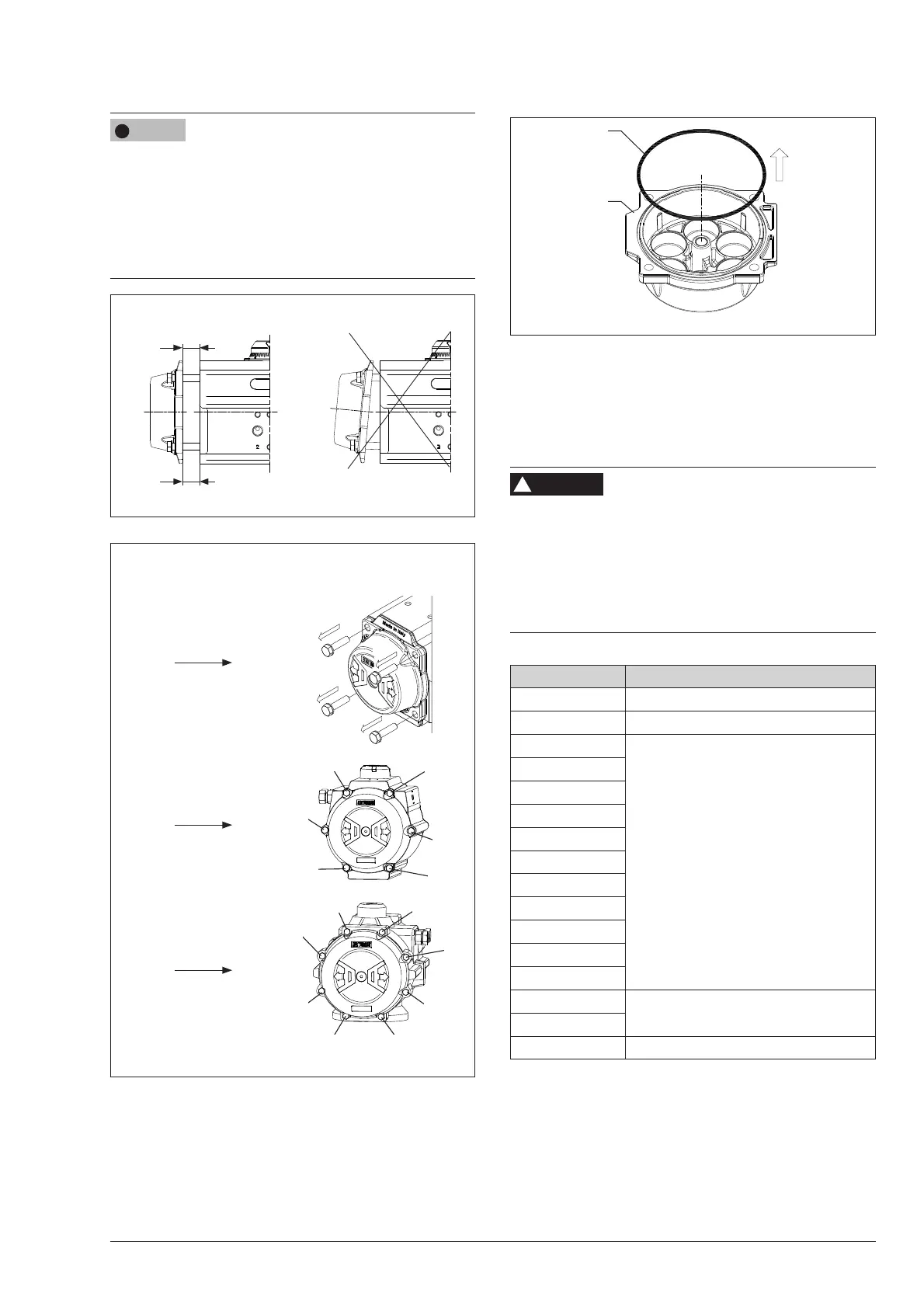

Î Observe the specied sequence shown in Fig. 9-5.

Fig. 9-4

B

A

A = B

Fig. 9-5

3

2

4

1

1

2

5

3

4

6

1

7

2

5

3 8

4

6

TOTAL QUANTITY OF

CAP SCREWS (13)

PER ACTUATOR:

− 8

− 12

− 16

SEQUENCE OF

DISASSEMBLY:

Fig. 9-6

14

30

30R

Spring return actuators

− Release the springs compression by partially unscrewing

each end cap bolt (13) 1 turn at a time as per the sequen-

ce shown in Fig. 9-5 for the number of turns indicated in

Table 9-2.

Risk of personal injury due to compressed springs.

End caps are under tension when the springs are compressed.

Î If there is still force on the end cap (30/30R) after

uscrewing the cap screws (13) for the number of turns in-

dicated in Table 9-3, the spring cartridge may have been

damaged or the pistons are not completely closed: stop

the disassembly and contact AIR TORQUE.

Table 9-3

ACTUATOR MODEL NUMBER OF TURNS FOR SCREWS (13)

AT045U 16 ÷18 turns

AT051U 26 ÷ 28 turns

AT101U

5 ÷ 7 turns

AT201U

AT251U

AT301U

AT351U

AT401U

AT451U

AT501U

AT551U

AT601U

AT651U

AT701U

6 ÷ 8 turns

AT751U

AT801U 8 ÷ 10 turns

− Completely unscrew and remove the end cap bolts (13)

− Remove the end caps (30).

− Remove the spring cartridges (17).

− Remove the o-rings (14). (Fig. 9-6)

NOTICE

!

WARNING

!

Loading...

Loading...