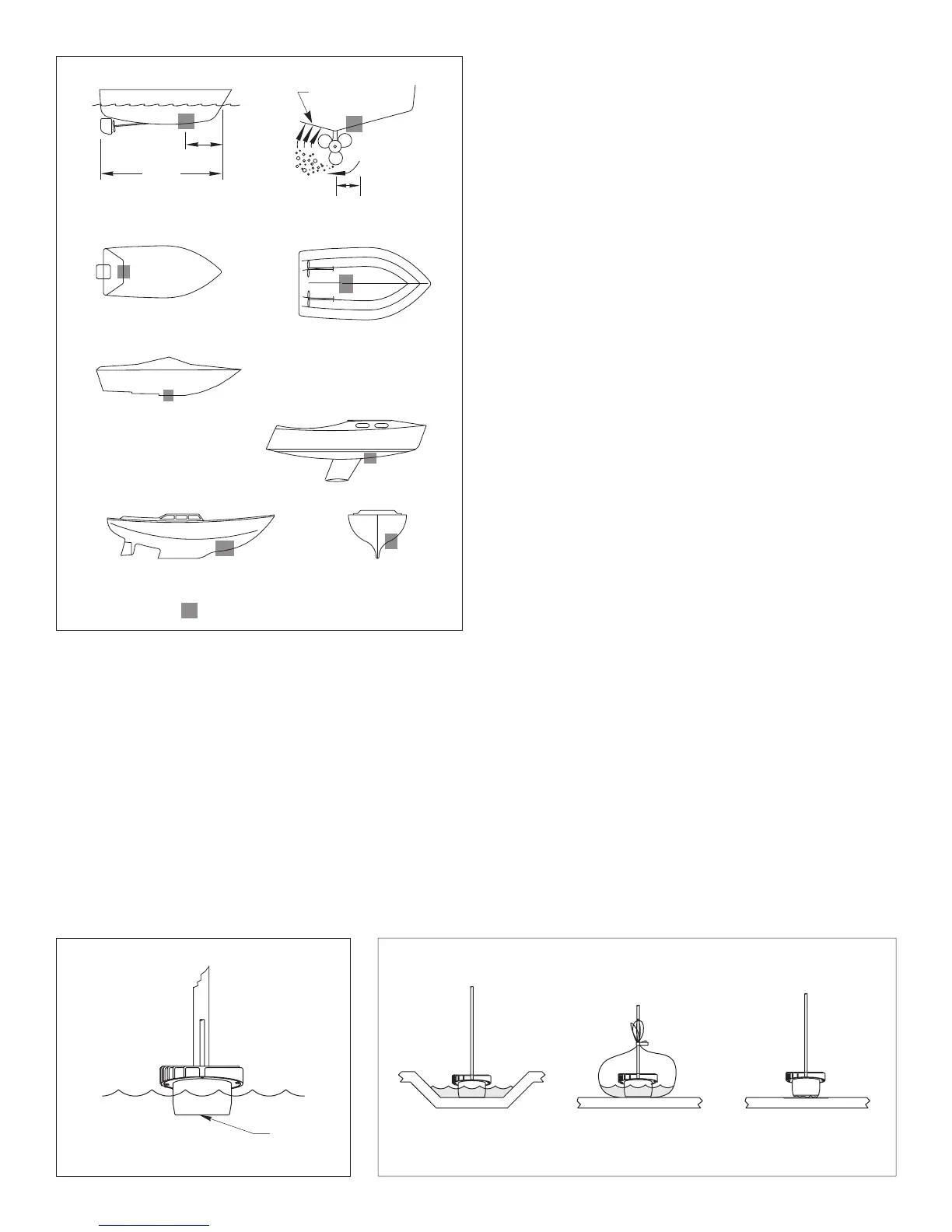

Boat Types

(see Figure 1)

•

Displacement hull powerboat

—Locate 1/3 aft LWL and

150–300mm (6–12") off the centerline on the side of the hull

where the propeller is moving downward.

•

Planing hull powerboat

—Mount well aft, on or near the

centerline, and

well inboard of the first set of lifting strakes

to

insure that the transducer is in contact with the water at high

speeds. Mount on the side of the hull where the propeller is

moving downward.

Outboard and I/O

—Mount just forward of the engine(s).

Inboard

—Mount well ahead of the propeller(s) and shaft(s).

Step-hull

—Mount just ahead of the first step.

•

Fin keel sailboat

—Mount to the side of the centerline and

forward of the fin keel 300–600mm (1–2').

•

Full keel sailboat

—Locate amidships and away from the keel

at the point of minimum deadrise angle.

Test the Selected Mounting Location

Establishing a Performance Baseline

The results of this test are used as a basis of comparison to

determine the best in-hull location for the sensor.

1. Take the boat to the maximum depth for which your instrument

is rated [up to 150m (500')] or the maximum depth in which you

will be operating the echosounder. If deep water is not available,

find a location with at least 30m (100').

2. Connect the transducer to the echosounder.

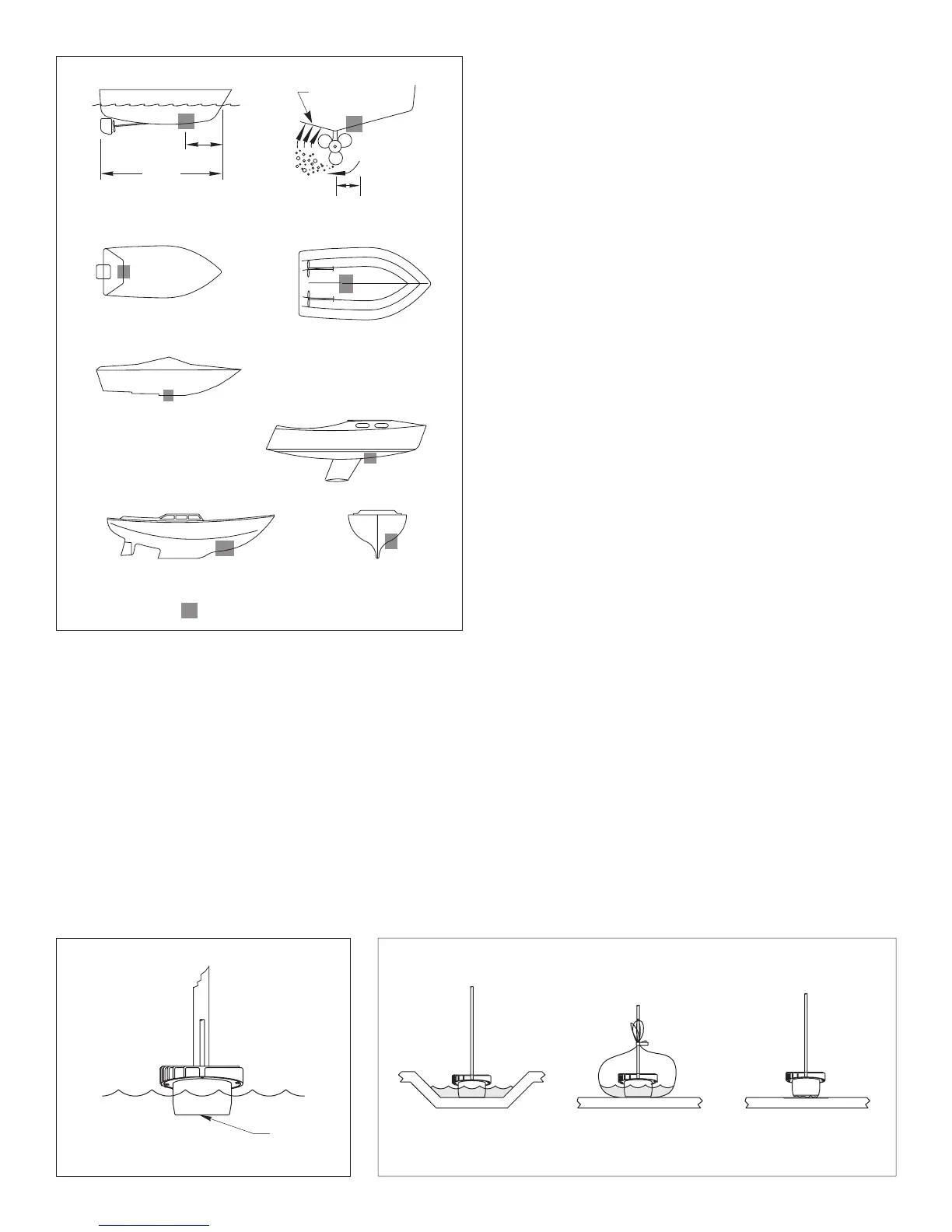

3. Tape the transducer to a pole with the cable side up. Hold it over

the side of the boat with the active face submerged in the water

(see Figure 2).

Be sure to keep the active face of the transducer

parallel to the surface of the water and fully submerged

.

4. Observe the echosounder’s performance and the depth

reading.

Testing the Mounting Location

While the boat is at the same site (depth of water), test the

transducer inside the hull at the mounting location. Use one of the

methods below:

A.This method is recommended if the sensor will be located near

the stern and the boat has a minimum deadrise angle. Clean

away any large build-up of dirt and/or grease using detergent or

a weak solvent such as alcohol. Place the transducer against

the hull and allow bilge water to cover the surface where they

touch (see Figure 3-A).

B.

Warning

: Always wear safety goggles and a dust mask.

This method can be used at any location. If the hull surface is not

smooth, grind it with a disc sander. Partially fill a thin plastic bag with

water, place the transducer inside the bag and close it tightly with a

twist-tie. Wet the surface of the hull and press the transducer’s

active face against it through the bag (see Figure 3-B).

C.

Warning

: Always wear safety goggles and a dust mask.

This method can be used at any location. If the hull surface is not

smooth, grind it with a disc sander. Coat the active face of the

transducer with a water-based lubricant (such as K-Y

®

jelly).

Press the active face against the hull with a twisting motion (see

Figure 3-C). After testing, wipe all traces of the lubricant from the

transducer’s face.

2

AIRMAR

®

inboard

Figure 1.

pressure waves

1/3 aft

full keel sailboat

displacement hull

(6-12")

fin keel sailboat

150-300mm

LWL

Best location for the transducer

(Load Waterline Length)

step-hull

planing hulls

Figure 2. Establishing a performance baseline

Figure 3. Testing the transducer at the selected location

AB C

active face

AIRMAR

®

AIRMAR

®

Loading...

Loading...