Observe the echosounder’s performance, and compare it to the

baseline. Look for a stable depth reading that is similar to the

baseline. If you are testing a fishfinder, compare the thickness and

intensity of the bottom trace.

If the performance is close to the baseline, this is a good mounting

location. Remember, some energy is lost transmitting through the

hull. If the test reading differs markedly from the baseline, you will

need to find another location to install the sensor.

If there is no reading or it is erratic, the transducer may be

positioned over coring which is absorbing the acoustic energy.

Choose another location. If no other spot is available,

check with

the boat manufacturer to be certain coring is present before

proceeding

with the instructions for “Installation in a Cored

Fiberglass Hull” on page 4.

Installation

1. Measure the deadrise angle of the hull at the selected location

using a digital level, or bubble level and protractor (see Figure 4).

Measure carefully, since the installed transducer must be within

5° of vertical.

Warning

: Always wear safety goggles and a dust mask.

2. The hull surface to be bonded must be smooth and free of paint

or any other finish. If the surface is rough, use a disk sander to

smooth an area 100mm (4") in diameter.

3. To ensure a tight bond, clean and dry both the selected area

and the underside of the base.Remove any dust, grease, or oil

with a weak solvent, such as alcohol.

4. Using a carpenter’s square, draw a line on the hull

perpendicular to the keel through the center of the mounting

location. This will be used as a guideline to orient the base.

5. The numbers on the flange of the base represent deadrise

angles. Identify the number that most closely corresponds to

the deadrise angle of your hull. Find its match on the opposite

side of the flange. Keeping the keel direction arrows on the side

of the base nearest the keel, align the two raised marks

indicating your deadrise angle with the guideline drawn on the

hull (see Figure 5).

Caution

: The base must be liquid-tight.

DO NOT use an epoxy adhesive, polyurethane based

sealant, or the previously recommended Boatlife® Life Seal®

or 3M™ 4200.

6. When you are satisfied that the location of the transducer is

optimal and the orientation of the base corresponds to the

deadrise angle of your boat, apply a bead of silicone sealant

(such as GE Silicone

I

or Silicone

II

) to the underside of the

flange of the base. (Follow the sealant manufacturer’s

instructions for its use.) Press the flange firmly in place to form

a liquid-tight seal. Allow the sealant to cure.

7. Slide the transducer into the locking ring. Turn the housing until

the rib that most closely corresponds to the deadrise angle of

your hull is aligned with the angle indicator on the locking ring.

To secure the housing to the locking ring, insert the two screws

(see Figure 6).

Do not

over-tighten the screws.

3

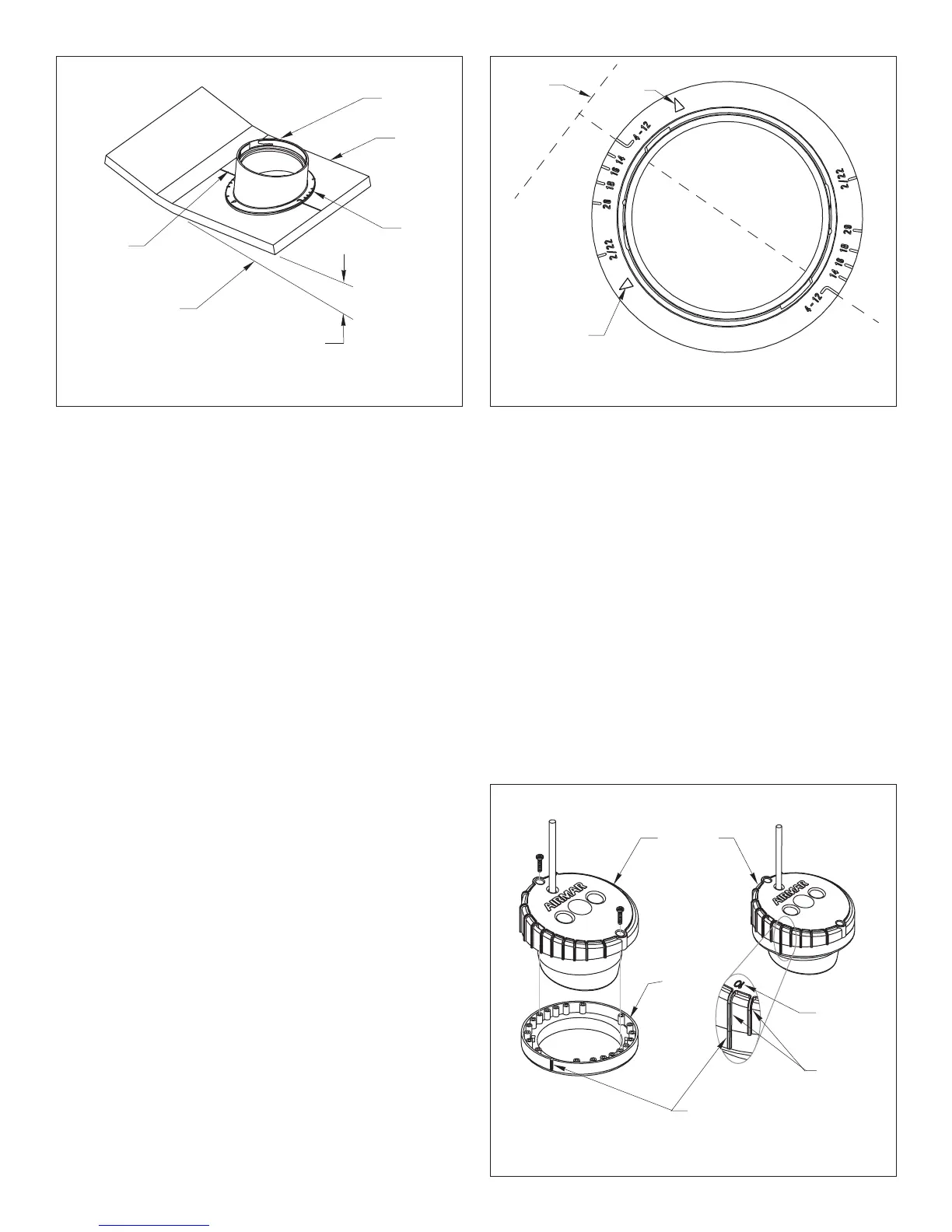

Figure 4. Deadrise angle

deadrise angle

parallel to

hull

waterline

perpendicular

to keel

base

flange

Figure 5. Aligning the flange of the base

keel direction

keel

direction

guideline

keel

arrow

arrow

(4°–12° deadrise angle shown)

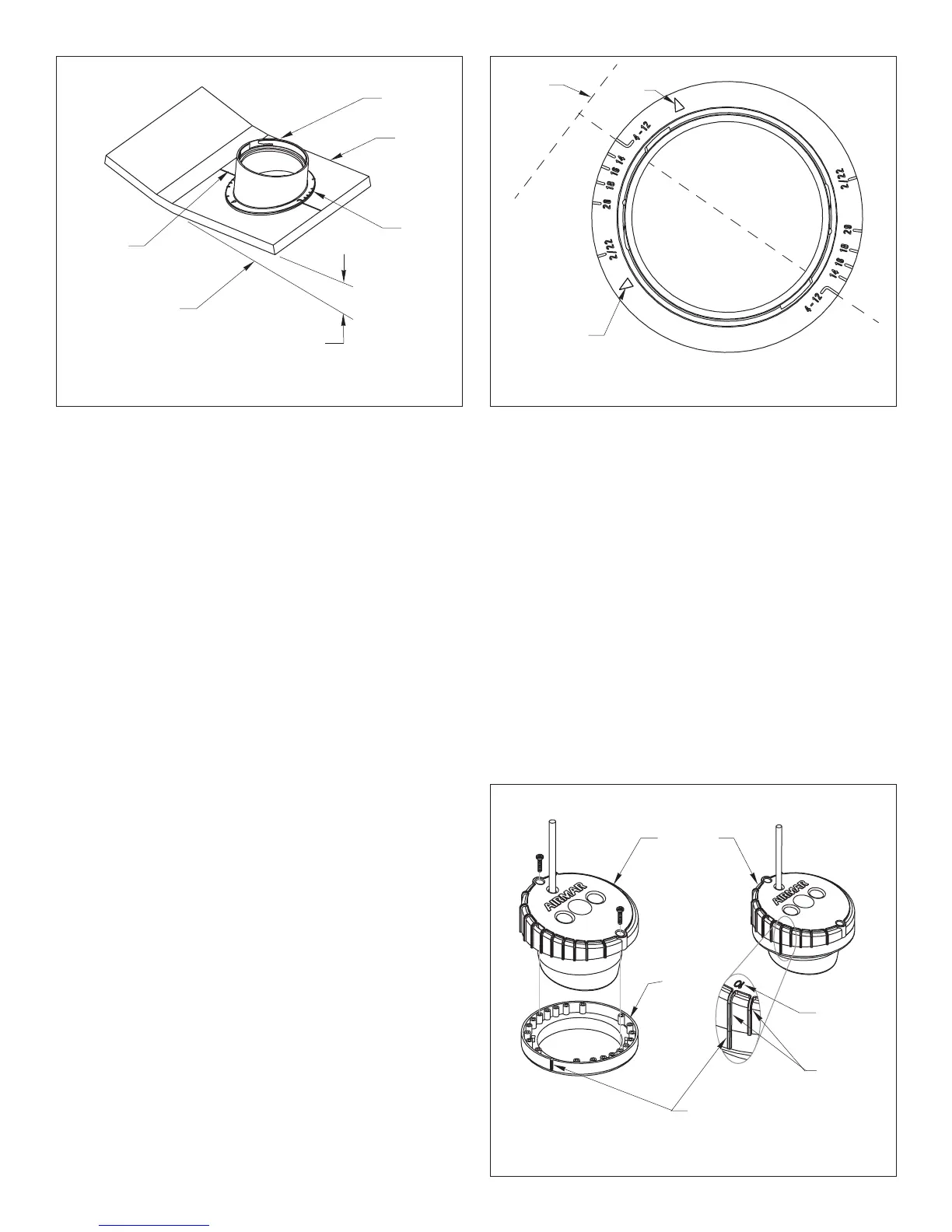

Figure 6. Joining the transducer to the locking ring

angle indicator

detail

locking

ring

transducer

ribs

10

•

deadrise

angle

shown

AIRMAR

®

AIRMAR

®

AIRMAR

®

Loading...

Loading...